Introduction

In industrial automation and process control, achieving precise and stable control of variables such as temperature, pressure, flow, and level is critical. One effective method to enhance control performance, particularly in systems with significant disturbances and lag, is cascade control. This article explores the principles, components, advantages, applications, and implementation of cascade control systems.

Understanding Cascade Control

Definition

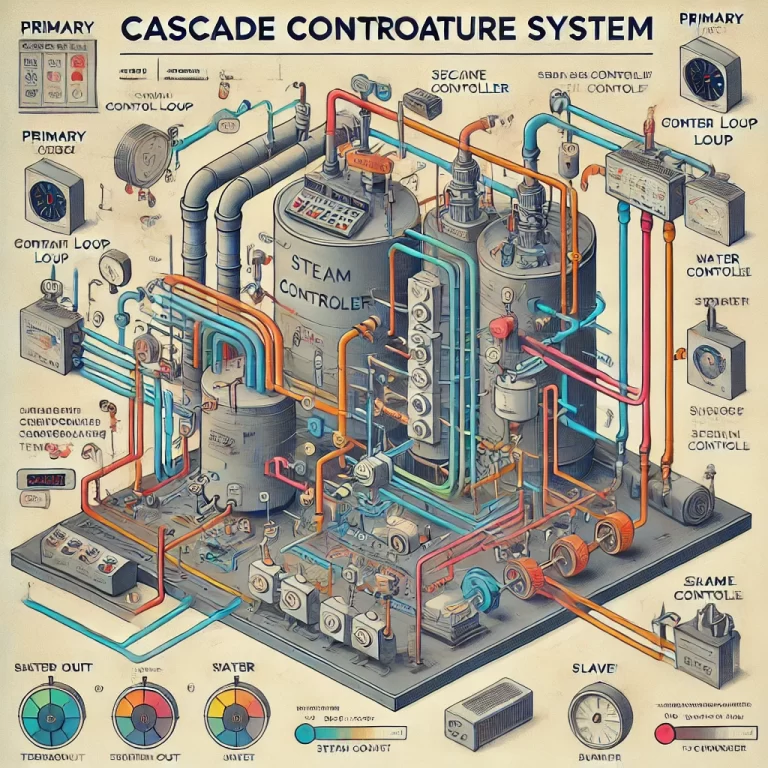

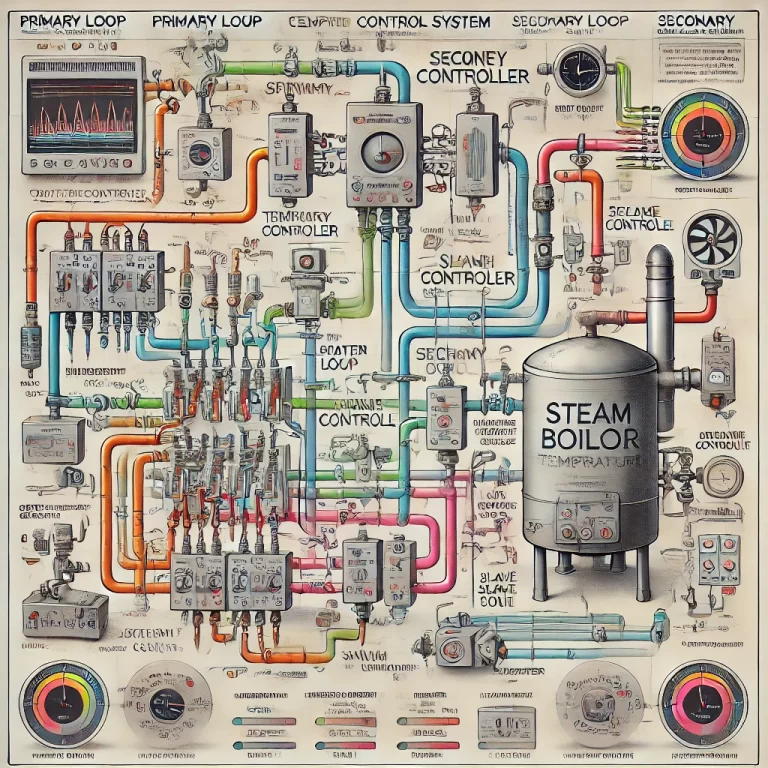

A cascade control system is a control strategy that employs two or more control loops in a hierarchical structure to improve system performance. The primary controller regulates the main process variable, while the secondary controller manages an intermediate variable that directly affects the primary process variable.

Structure and Components

A basic cascade control system consists of two control loops:

Primary (Outer) Loop: This loop monitors the primary process variable (e.g., temperature, pressure) and sends a control signal to the secondary loop.

Secondary (Inner) Loop: This loop monitors an intermediate process variable (e.g., flow rate, steam pressure) and directly influences the actuator.

The primary controller (Master Controller) provides a setpoint to the secondary controller (Slave Controller), which in turn adjusts the final control element (such as a control valve, motor speed, or heating element).

Working Principle

The primary controller measures the main process variable and compares it to the setpoint.

The primary controller generates an output that acts as the setpoint for the secondary controller.

The secondary controller regulates an intermediate process variable by adjusting the actuator.

The system responds faster to disturbances at the secondary loop level, improving overall control performance.

Advantages of Cascade Control

Cascade control offers several advantages over single-loop control systems:

Improved Disturbance Rejection: The secondary loop quickly corrects disturbances before they affect the primary process variable.

Faster System Response: Inner loops handle fast-changing dynamics, reducing overall response time.

Better Control Precision: By controlling an intermediate variable, the system achieves more stable and accurate control.

Reduced Effect of Process Lag: The inner loop compensates for delays and enhances the main loop’s stability.

Enhanced Process Safety: More reliable control minimizes fluctuations that could lead to unsafe operating conditions.

Applications of Cascade Control

Cascade control is widely used in industries where precise process regulation is essential. Some common applications include:

Temperature Control in Chemical Reactors

Primary Loop: Controls the reactor temperature.

Secondary Loop: Regulates coolant or steam flow to maintain the desired temperature.

Steam Boiler Pressure Control

Primary Loop: Controls steam pressure.

Secondary Loop: Adjusts fuel flow rate to regulate combustion.

Liquid Level Control in Tanks

Primary Loop: Maintains liquid level.

Secondary Loop: Adjusts feed pump flow rate.

Motor Speed Control in Conveyors

Primary Loop: Maintains material flow rate.

Secondary Loop: Adjusts motor speed to achieve desired throughput.

Implementation Considerations

When designing and implementing a cascade control system, the following factors should be considered:

Selecting Appropriate Process Variables

The secondary loop should regulate a variable that directly affects the primary variable.

Tuning of Controllers

The inner loop should be faster than the outer loop.

Inner loop tuning: Use faster response times and smaller integral time.

Outer loop tuning: Use slower response times to avoid excessive oscillations.

Sensor Placement and Accuracy

The sensors used in both loops should provide accurate and reliable readings to avoid errors in control.

Controller Compatibility

The primary and secondary controllers should be able to communicate effectively, often requiring digital or analog integration.

Comparing Cascade Control to Other Strategies

| Control Strategy | Structure | Advantages | Limitations |

|---|---|---|---|

| Single-Loop Control | One control loop | Simple, easy to implement | Slower response, sensitive to disturbances |

| Cascade Control | Two nested loops | Faster response, better disturbance rejection | Requires more sensors and tuning |

| Feedforward Control | Predicts disturbances | Quick compensation | Needs accurate disturbance models |

| Adaptive Control | Adjusts parameters in real-time | Handles varying conditions | Complex and computationally demanding |

Conclusion

Cascade control is an effective method for improving the stability, accuracy, and responsiveness of industrial process control systems. By utilizing an inner loop to regulate fast-changing intermediate variables, it enhances the overall performance of the main control loop. Its widespread application across industries such as chemical processing, power generation, and manufacturing highlights its effectiveness in ensuring efficient, stable, and reliable operations.

For successful implementation, engineers must carefully select process variables, tune controllers, and integrate sensors to achieve optimal performance. As automation continues to advance, cascade control remains a cornerstone strategy for achieving precision in industrial control systems.