When Carbide Dust Meets Acetylene Gas: Risks and Protective Measures

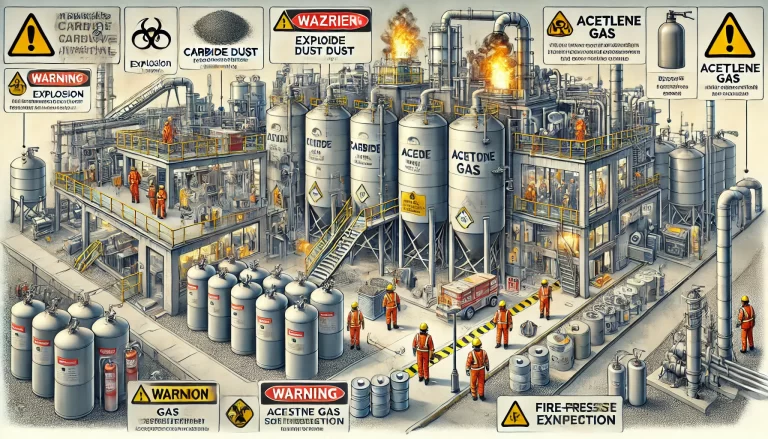

In the chemical industry, carbide dust and acetylene gas play crucial roles in various production and manufacturing processes. However, their inherent explosiveness, flammability, and corrosiveness pose significant risks, requiring stringent safety measures and careful handling practices. Ensuring workplace safety, equipment reliability, and environmental protection represents a fundamental challenge within the industry.

1. Hazards of Carbide Dust and Necessary Protective Equipment

Carbide dust, generated in high-temperature electric arc furnaces from the reaction of limestone and coke, is an unavoidable byproduct. It poses significant risks due to its interaction with moisture and its impact on human health and the environment.

1.1 Explosion Hazards Carbide dust readily reacts with moisture to produce acetylene gas, a highly explosive substance. When carbide dust mixes with air, it forms combustible mixtures that can trigger devastating explosions, endangering workers and equipment.

1.2 Health Risks Exposure to carbide dust may lead to serious respiratory conditions, including pneumoconiosis (dust lung disease), and may also irritate eyes and skin.

1.3 Environmental Impact Uncontrolled carbide dust emissions contaminate air, soil, and water, negatively affecting ecosystems and community health.

Protective Equipment for Carbide Dust:

Dust Collection Systems: High-efficiency filtration equipment such as baghouse collectors, electrostatic precipitators, and wet scrubbers significantly reduce airborne dust concentrations.

Level Measurement Instruments: Accurate monitoring of carbide dust levels in storage silos is essential to prevent operational disruptions or material spillage. Key equipment includes:

Vibrating Fork Level Switches: Reliable for precise detection of dust levels.

RF Admittance Level Switches: Highly sensitive instruments ideal for dry powders.

Vibrating Rod Level Switches: Effective in monitoring dry and granular materials.

2. Hazards of Acetylene Gas and Safety Equipment

Acetylene gas, produced through the reaction of carbide with water, is widely used in chemical synthesis, welding, and metal-cutting applications. Its inherent instability and corrosiveness demand comprehensive protective strategies during production, storage, and transportation.

2.1 Explosivity Acetylene gas mixed with air presents a wide explosive range. Even small concentrations can lead to severe explosions, necessitating vigilant management of gas mixtures in industrial environments.

2.2 Corrosiveness and Toxicity Acetylene’s corrosive properties threaten equipment integrity and performance, while its toxicity at high concentrations poses severe health risks, potentially causing poisoning and asphyxiation.

Protective Equipment for Acetylene Gas:

Acetylene Generators: Devices designed to withstand high pressures and ensure airtight sealing, preventing leaks and accidental gas release.

Gas Storage Cylinders: Specialized cylinders filled with stabilizing materials such as diatomaceous earth and activated charcoal, equipped with pressure regulators and relief valves to minimize explosion risks.

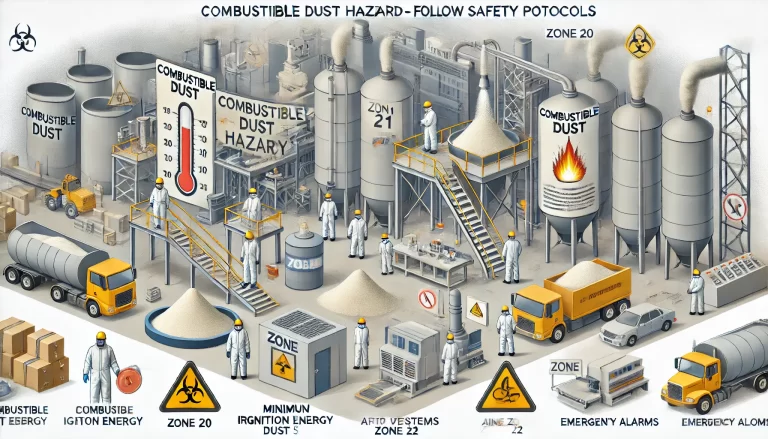

3. Comprehensive Safety Measures for Handling Carbide Dust and Acetylene Gas

Ensuring comprehensive safety requires integrating advanced monitoring systems, robust equipment, and rigorous operational procedures.

3.1 Explosion-Proof and Monitoring Systems

Gas Leak Detection Systems: Installing high-sensitivity sensors and alarms for real-time monitoring of acetylene gas concentrations.

Dust Concentration Monitoring: Deploying sensors in dust-prone areas to maintain safe dust concentration levels.

Certified Explosion-Proof Equipment: Equipment used in handling carbide dust and acetylene gas must comply with international standards such as IECEx and ATEX, including explosion-proof electrical equipment, switches, lighting systems, pipelines, and valves.

3.2 Automatic Fire Suppression and Emergency Response

Automated Fire Suppression Systems: Strategically installed in areas handling carbide dust and acetylene gas, these systems rapidly suppress fires, minimizing potential damage.

Emergency Response Plans: Comprehensive and detailed emergency protocols to ensure effective response in cases of gas leaks, equipment failures, or fires.

Conclusion

The safe management of carbide dust and acetylene gas is critical to chemical industry operations. Technological advancements continue to enhance safety, automation, and environmental compatibility of processes involving these hazardous substances. Strict adherence to safety standards and best practices ensures employee protection, equipment longevity, environmental stewardship, and sustained industrial efficiency.