In modern ship design and operations, the accuracy and reliability of liquid level measurement are of paramount importance. As an advanced measurement technology, radar level gauges have been widely applied in various fields. This article explores whether radar level gauges are suitable for measuring liquid levels in ballast tanks, analyzing their advantages, limitations, and practical applications.

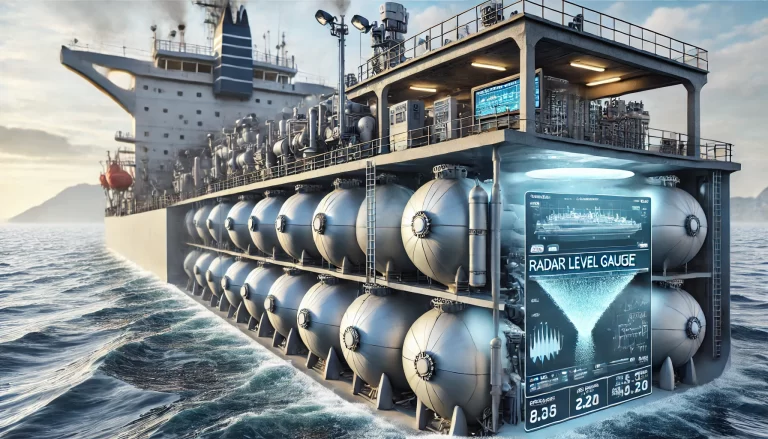

1. Principles of Radar Level Gauges

Radar level gauges operate by emitting electromagnetic waves and receiving the reflected signals to measure the liquid level. The working principle is based on the propagation speed of electromagnetic waves and the time difference between emission and reception, which is used to calculate the distance to the liquid surface.

This technology offers several distinct advantages:

- High Precision: Radar level gauges deliver highly accurate measurements, typically with an error margin of ±5mm, making them ideal for applications requiring precision.

- Non-Contact Measurement: As they do not require direct contact with the liquid, these devices avoid contamination and corrosion, making them suitable for harsh and diverse environments.

- Multi-Parameter Integration: Many radar level gauges can integrate additional parameters such as temperature and pressure, providing comprehensive monitoring data.

- Ease of Maintenance: Installed at the top of tanks, these devices are easy to access and maintain, even in challenging conditions.

- Environmental Adaptability: Radar level gauges function reliably in adverse environments, including high humidity, high temperature, and corrosive atmospheres.

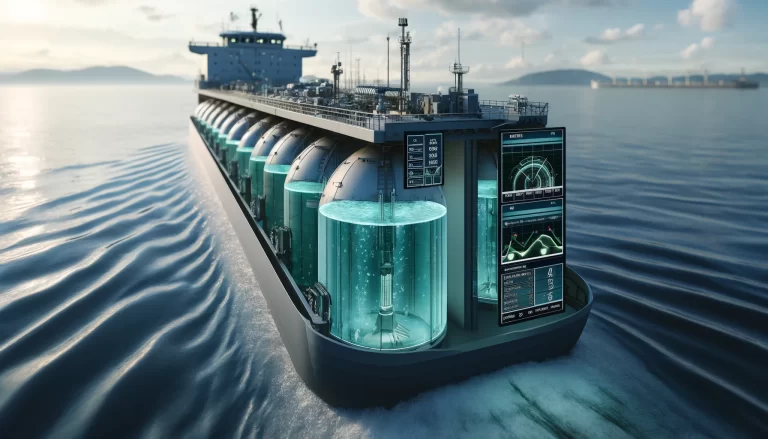

2. Importance of Liquid Level Measurement in Ballast Tanks

Ballast tanks are critical components of ships, used to adjust stability and buoyancy. Accurate liquid level measurement in ballast tanks is essential for ensuring safe operations. Key challenges in this application include dealing with extreme environmental conditions, such as high moisture, corrosive sea water, and confined spaces.

3. Application of Radar Level Gauges in Ballast Tanks

Advantages in Ballast Tank Monitoring

Radar level gauges are well-suited for ballast tank liquid level measurement due to their advanced features:

- Non-Contact Measurement: Their non-intrusive nature allows effective functioning in humid and corrosive conditions.

- High Accuracy and Stability: These gauges provide reliable, real-time monitoring of liquid levels, which is critical for maintaining ship stability.

- Enhanced Monitoring Capabilities: Advanced radar level gauges (e.g., Honeywell’s EM540 model) integrate parameters like temperature and pressure, enabling comprehensive tank monitoring solutions.

- Seamless Data Transmission: The data from these devices can be transmitted securely to the ship’s central monitoring system or Integrated Control and Monitoring Systems (ICMS), facilitating remote management and real-time analysis.

Real-World Implementations

Companies such as Honeywell have validated the effectiveness of radar level gauges in various maritime applications, including oil tankers, chemical carriers, and inland ships. These devices are not only adept at measuring cargo tank levels but also excel in monitoring ballast tanks and other specialized compartments.

4. Limitations and Challenges

Despite their significant advantages, radar level gauges face certain limitations:

- High Initial Cost: Compared to traditional mechanical or pressure sensor-based gauges, radar systems involve higher procurement costs, which may increase upfront investment.

- Complex Installation and Commissioning: These systems require professional technical support for installation and calibration, demanding a higher level of expertise from operators.

- Potential Interference: Although radar level gauges have robust anti-interference capabilities, extreme conditions—such as strong electromagnetic interference or highly dense metallic environments—may impact performance.

- Maintenance in Challenging Conditions: While they are generally low-maintenance, specific tank environments might necessitate periodic recalibration to maintain accuracy.

5. Conclusion and Future Directions

Radar level gauges represent an advanced liquid level measurement technology, perfectly suited for ballast tank monitoring. Their high precision, non-contact nature, multi-functional integration, and environmental adaptability make them indispensable in modern maritime operations. While the costs and technical complexity of these systems may pose challenges, the resulting improvements in safety, reliability, and operational efficiency justify the investment.

Moving forward, continued advancements in radar technology, such as enhanced signal processing algorithms and more compact designs, are expected to further expand their applicability in maritime industries. Additionally, incorporating AI and IoT capabilities could unlock new possibilities for predictive maintenance and automated monitoring, ensuring that radar level gauges remain at the forefront of liquid measurement technology.

By addressing both the advantages and limitations of radar level gauges in ballast tank applications, this article provides a comprehensive perspective on their practical value and future potential. For ship designers, operators, and maritime engineers, radar level gauges represent a cutting-edge solution that combines precision with durability, making them an essential component of modern vessel management systems.