The integration of instrumentation and metrology has long been viewed as a challenge due to their distinct roles in industrial operations. However, with the rise of intelligent, multifunctional tools, this boundary is becoming increasingly blurred. This article explores the potential and limitations of merging these two domains from the perspectives of tool efficiency and professional specialization.

1. Deep Integration of Instrumentation and Calibration through Smart Tools

The evolution of multifunctional and intelligent tools is reshaping how we approach both measurement and calibration. A prime example is Fluke, a global leader in test and measurement technology. Several of their tools now combine both instrumentation and calibration functions.

Take the Fluke 754/754PLUS Documenting Process Calibrator—a powerful and reliable device for maintaining and troubleshooting HART and other field instruments. It integrates HART communication and enables users to simulate, source, and measure pressure, temperature, and electrical signals in one handheld unit.

Another example is the Fluke 773 Milliamp Process Clamp Meter, which allows technicians to measure and troubleshoot 4-20 mA control loops without breaking the circuit or shutting down the system—saving considerable time and effort.

These smart tools, equipped with microprocessors and embedded sensors, offer real-time measurement, calibration, data logging, error correction, and remote communication. They transform the traditional “measure first, calibrate later” workflow into a dynamic closed-loop system, enabling metrology to shift from post-event supervision to in-process control.

2. The Fundamental Distinction Between Instrumentation and Metrology

Despite technical convergence, the core philosophies of instrumentation and metrology remain fundamentally different.

Instrumentation focuses on functional performance: accurately displaying voltage, current, or other physical quantities and transmitting control signals. It is the executor in industrial systems.

Metrology, on the other hand, is about traceability and standardization of measurements. It is the referee, ensuring consistency and accuracy through national or international standards.

While instrumentation evolves around hardware performance and protocol compatibility, metrology emphasizes quantified standards, traceability chains, and compliance with regulations.

Instrumentation seeks broader application versatility, while metrology enforces stricter baseline constraints. These differing goals highlight that while integration at the operational level is feasible, professional separation at the conceptual and regulatory level remains essential.

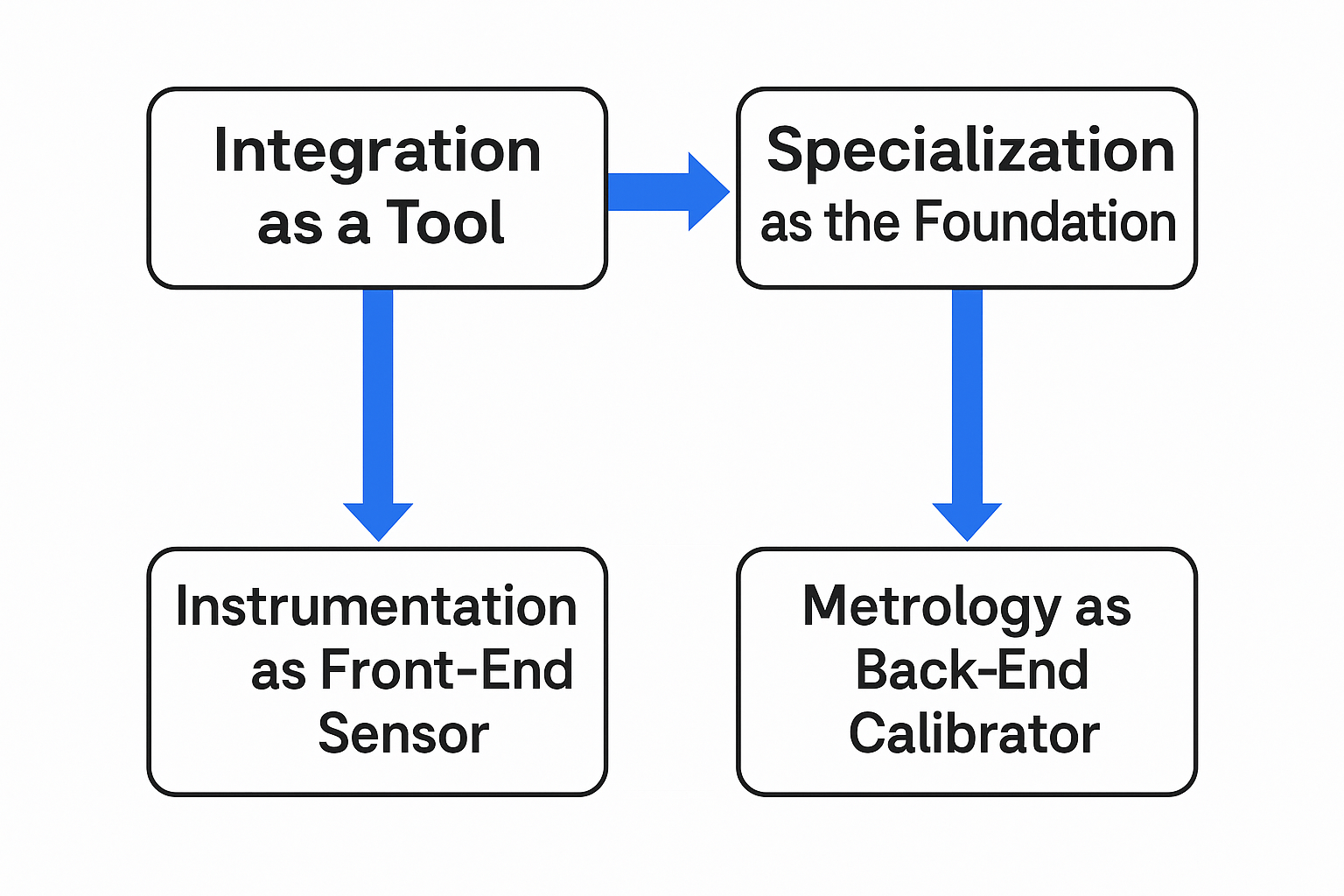

3. Integration as a Tool, Specialization as the Foundation

Smart tools can indeed blur the line between operation and calibration, allowing one device to handle tasks that previously required multiple specialists. But efficiency should not replace expertise.

Looking forward, the optimal model is collaborative coexistence:

Let instrumentation act as the front-end sensor, responsible for real-time data acquisition and control execution.

Let metrology function as the back-end calibrator, ensuring that all values remain accurate, standardized, and traceable.

This model supports the trend toward cross-disciplinary collaboration—meeting both the efficiency needs of instrumentation and the compliance demands of metrology.

💬 So, Can They Truly Be Combined?

High-efficiency tools have the power to integrate operations, but not to merge the disciplines entirely. Instrumentation and metrology may walk hand in hand in practice, yet their professional cores should remain distinct to preserve accuracy, reliability, and system integrity.