A Technical Perspective for Instrumentation Engineers

Lightning-induced surges remain one of the most significant threats to field instruments in industrial facilities. A single failure of surge protection may lead to instrument malfunction, unexpected plant shutdown, or even major safety incidents.

Recently, a common question has generated discussion among instrumentation engineers:

“If an instrument has passed an entrusted surge test according to a product standard, can that report be used as evidence that the instrument meets the customer’s lightning protection requirements?”

This article provides a clear and authoritative answer, supported by relevant international and industry standards.

1. Why the Confusion Exists

Instrument manufacturers or integrators often commission third-party laboratories to conduct surge immunity tests based on electronic product standards. These reports typically show compliance with EMC or overvoltage category requirements.

However, end users—especially in petrochemical, power, water, and large industrial facilities—frequently require compliance with lightning protection standards, not just generic surge immunity.

This leads to the core question:

Does a standard EMC surge test equal lightning surge protection capability?

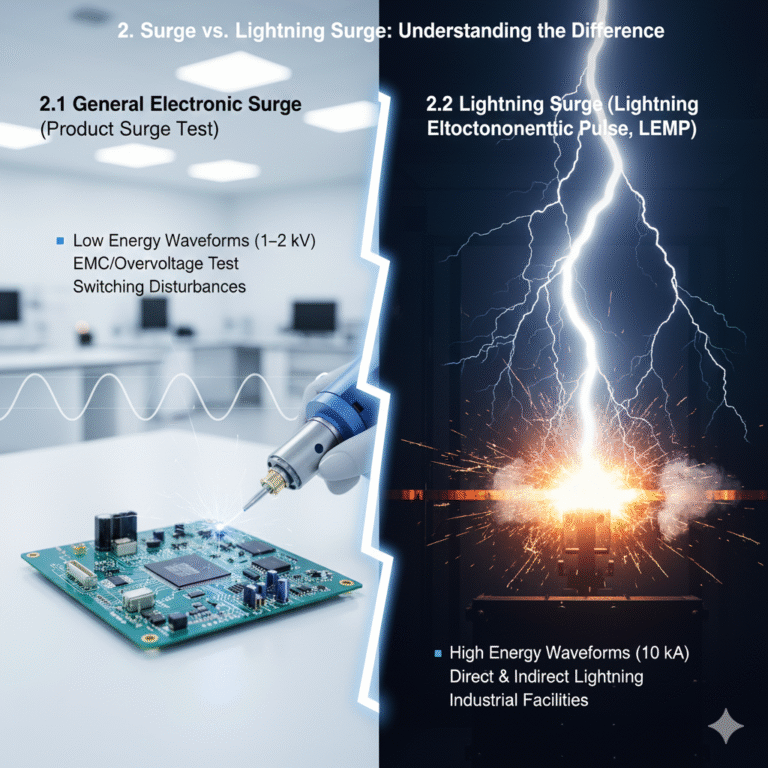

2. Surge vs. Lightning Surge: Understanding the Difference

The term “surge” is often used loosely, but standards make a clear distinction:

2.1 General Electronic Surge (Product Surge Test)

Defined as a transient overvoltage or overcurrent caused by switching operations, load changes, or random electromagnetic disturbances.

Used in EMC testing to evaluate equipment robustness under typical electrical disturbances.

Test waveforms and energy levels are much lower than lightning-induced surges.

2.2 Lightning Surge (Lightning Electromagnetic Pulse, LEMP)

Defined in GB 50057 and IEC lightning protection standards as “electrical surges induced by lightning electromagnetic effects.”

Energy level, waveform, and failure mechanism are fundamentally different.

Requires specialized surge protective device (SPD) testing methodology.

Therefore, a general surge immunity report cannot be assumed to represent lightning protection capability.

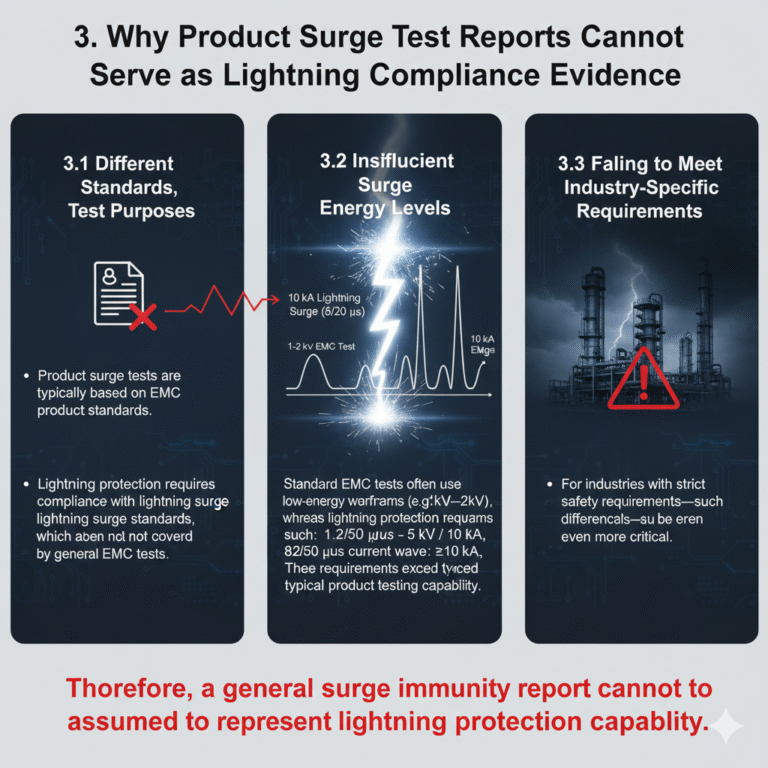

3. Why Product Surge Test Reports Cannot Serve as Lightning Compliance Evidence

3.1 Different Standards, Different Test Purposes

Product surge tests are typically based on EMC product standards.

Lightning protection requires compliance with lightning surge standards, which are not covered by general EMC tests.

3.2 Insufficient Surge Energy Levels

Standard EMC tests often use low-energy waveforms (e.g., 1kV–2kV), whereas lightning protection requires waveforms such as:

1.2/50 μs – 8/20 μs combination wave: 5 kV / 10 kA

8/20 μs current wave: ≥10 kA

These requirements exceed typical product testing capability.

3.3 Failing to Meet Industry-Specific Requirements

For industries with strict safety requirements—such as petrochemicals—the difference is even more critical.

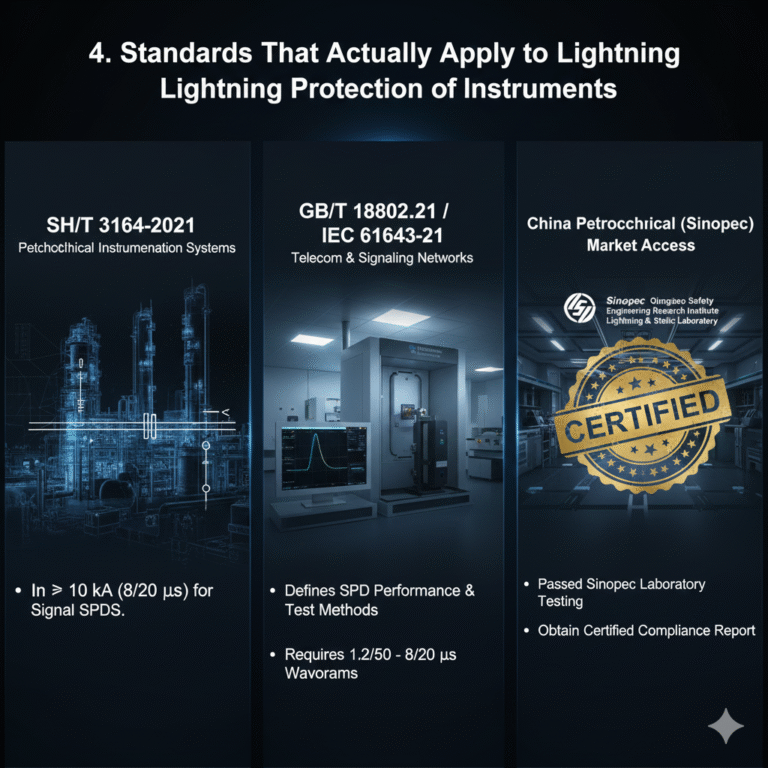

4. Standards That Actually Apply to Lightning Protection of Instruments

To meet lightning surge protection requirements, instrument SPDs (including built-in SPDs) must comply with the following standards:

4.1 SH/T 3164-2021

“Lightning Protection Design Code for Petrochemical Instrumentation Systems”**

Internal SPDs must meet the same performance criteria as external SPDs.

Nominal discharge current In ≥ 10 kA (8/20 μs) for signal surge protectors.

4.2 GB/T 18802.21 / IEC 61643-21

“Surge Protective Devices for Telecommunication and Signaling Networks”**

Defines SPD performance requirements and testing methods.

Requires test equipment capable of 1.2/50–8/20 μs combination waves or 8/20 μs current waves.

4.3 China Petrochemical (Sinopec) Market Access Requirements

Instruments used in Sinopec projects must pass testing at the

Sinopec Qingdao Safety Engineering Research Institute Lightning & Static Laboratory

and obtain a certified compliance report.

5. Internal vs. External Surge Protection: Why External SPDs Are Often Recommended

Many instrument manufacturers do not specialize in lightning protection technology. As a result:

Built-in SPDs often provide basic surge immunity, not full lightning protection.

Built-in designs typically use small components with limited discharge capability.

External SPDs from professional manufacturers can handle much higher energy levels.

For high-risk applications, industry standards generally recommend using external, professionally manufactured SPDs to protect instrument loops and communication lines.

6. When Is Testing Required?

Lightning surge testing is not mandatory unless required by the customer or regulatory authority.

If testing is required:

It must be conducted by laboratories capable of generating lightning surge waveforms.

Alternatively, the manufacturer must perform tests and issue a conformity report based on lightning protection standards.

7. Final Conclusion (Clear Answer for Customers and Engineers)

A general surge test report conducted according to electronic product standards

cannot be used as valid evidence for lightning protection compliance.

To meet lightning protection requirements, instruments must comply with:

Lightning surge standards (e.g., GB/T 18802.21 / IEC 61643-21)

Industry-specific specifications (e.g., SH/T 3164-2021)

User or project management requirements (e.g., Sinopec certification)

In critical industrial environments, relying solely on internal surge protection is insufficient—external professional SPDs are strongly recommended.