Introduction

Tuning fork level switches and flow switches have different core principles and applications. A tuning fork level switch is specifically designed to detect liquid levels rather than flow rates.

However, in certain specific situations, the characteristics of a tuning fork level switch may be indirectly used for controlling or monitoring flow-related activities. Despite this potential, it does not mean that a tuning fork level switch can replace or serve as a flow switch directly.

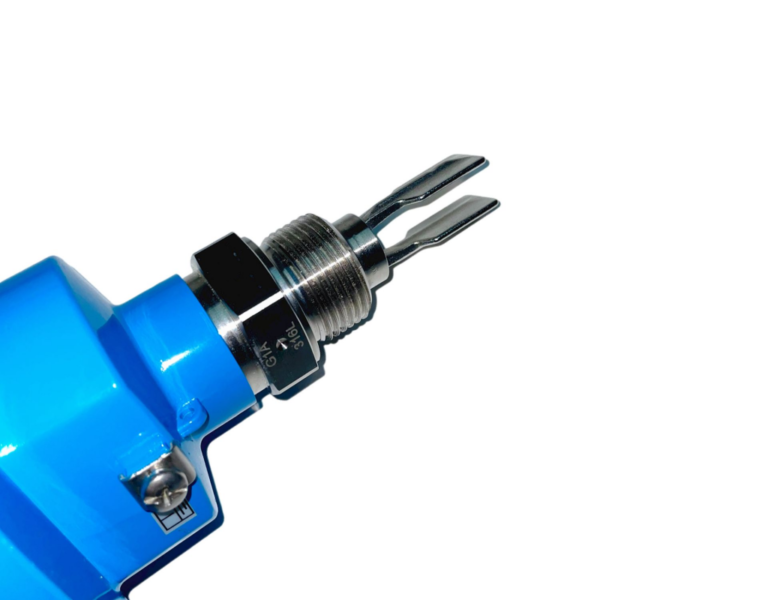

How Tuning Fork Level Switches Work

The tuning fork level switch operates based on vibrations. The core component consists of a carefully designed pair of tuning forks that vibrate at a specific frequency. When the tuning forks come into contact with a liquid, the density and damping characteristics of the liquid affect the vibration, causing changes in frequency, amplitude, or phase.

These changes are captured by a sensitive sensor that converts them into an electrical signal, which subsequently triggers a switch output. The signal output can switch from “off” to “on,” allowing the switch to detect and control liquid levels. This is useful in applications where monitoring the presence or absence of liquid is crucial, such as in storage tanks, chemical reactors, and water reservoirs.

How Flow Switches Work

In contrast, a flow switch is designed to detect the presence or absence of fluid flow in a pipeline, such as water, air, or gas flow. Depending on the flow rate, the switch triggers alarms or control signals to take necessary actions.

There are various types of flow switches, such as paddle-type or electronic flow switches, each operating on different principles. For instance, a water flow switch in the cold water inlet of a gas water heater ensures that when the water flow is below a certain level, the heater does not activate, thus enhancing safety. These switches rely on fluid movement to monitor and control flow parameters.

Key Differences Between Tuning Fork Level Switches and Flow Switches

Purpose:

- Tuning Fork Level Switch: Used primarily to detect and control liquid levels.

- Flow Switch: Focuses on monitoring and controlling fluid flow rates.

Working Principle:

- Tuning Fork Level Switch: Detects changes in the vibration frequency of tuning forks to measure liquid levels.

- Flow Switch: Detects fluid flow characteristics to trigger a control signal.

Applications:

- Tuning Fork Level Switch: Commonly used in applications requiring liquid level monitoring, such as water tanks, chemical reactors, and reservoirs.

- Flow Switch: Frequently applied where fluid flow monitoring and control are required, such as in water systems, air conditioning systems, and petrochemical industries.

Conclusion

In conclusion, while a tuning fork level switch is not suitable for direct use as a flow switch, it can be applied in some specific cases where liquid level changes indirectly reflect flow changes. For example, in a water treatment system, monitoring water levels can help control pumps and regulate water flow. However, this does not change the core design and working principle of a tuning fork level switch.

When selecting equipment for liquid level or flow control, it is important to choose the correct device type based on the specific application scenario and requirements.