In industrial automation, Programmable Logic Controllers (PLCs) are the backbone of reliable and repeatable control systems. But one common question from engineers and end users alike is:

Can a PLC function without an HMI (Human-Machine Interface) or SCADA (Supervisory Control and Data Acquisition) system?

The short answer is yes — a PLC can absolutely run without an HMI or SCADA. Let’s explore what this means in practice.

✅ What Does a PLC Do?

A PLC is a digital computer used to automate electromechanical processes. It performs tasks such as:

Starting and stopping motors

Controlling valves and pumps

Monitoring sensors (temperature, pressure, flow, etc.)

Executing logical decisions based on inputs and timers

Once the control logic is programmed and downloaded to the PLC, it operates autonomously, continuously executing the program cycle.

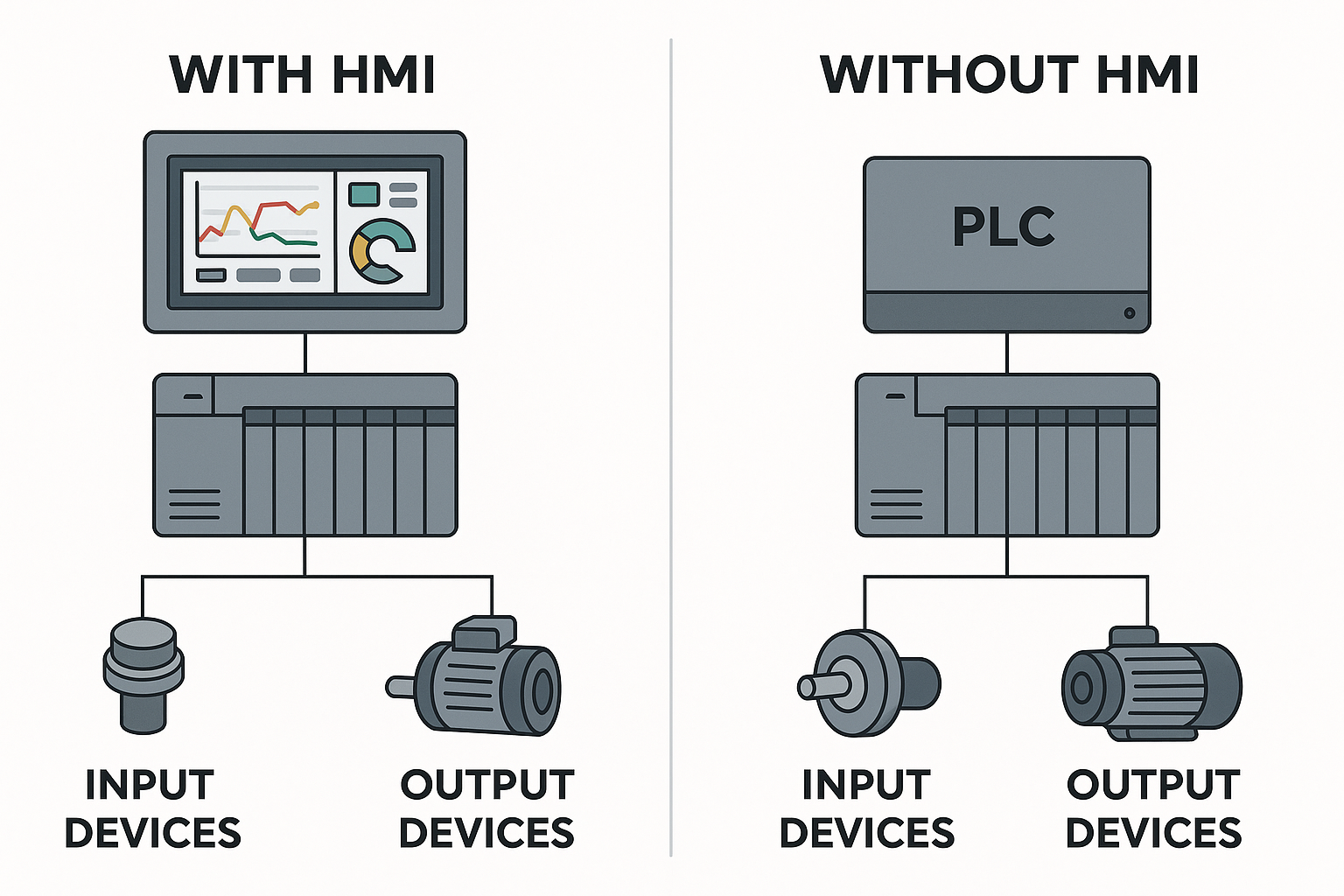

🔧 What Happens Without an HMI or SCADA?

Although the PLC itself can operate independently, removing the HMI or SCADA limits operator interaction and system visibility.

| Functionality | With HMI/SCADA | Without HMI/SCADA |

|---|---|---|

| System Monitoring | Real-time data, alarms, trends | No visual feedback |

| User Interaction | Buttons, touchscreens, input forms | Manual switches or none |

| Data Logging | Historical records, alarm history | Limited or no logging |

| Remote Access | Web interface, remote control possible | Requires direct PLC software access |

Without an HMI or SCADA, troubleshooting, status checking, and manual overrides become more difficult.

🏭 When Is It Acceptable to Omit HMI/SCADA?

There are valid scenarios where HMIs or SCADA are not necessary:

Small-Scale Automation: Simple systems like pump control, lighting, or fan start/stop.

Fixed-Logic Systems: Equipment that runs without operator intervention (e.g., a timer-based irrigation system).

Pre-commissioning or Testing: Systems under initial development or testing may not yet have an interface.

Low-Budget Installations: For cost-sensitive projects, HMIs may be excluded to reduce expenses.

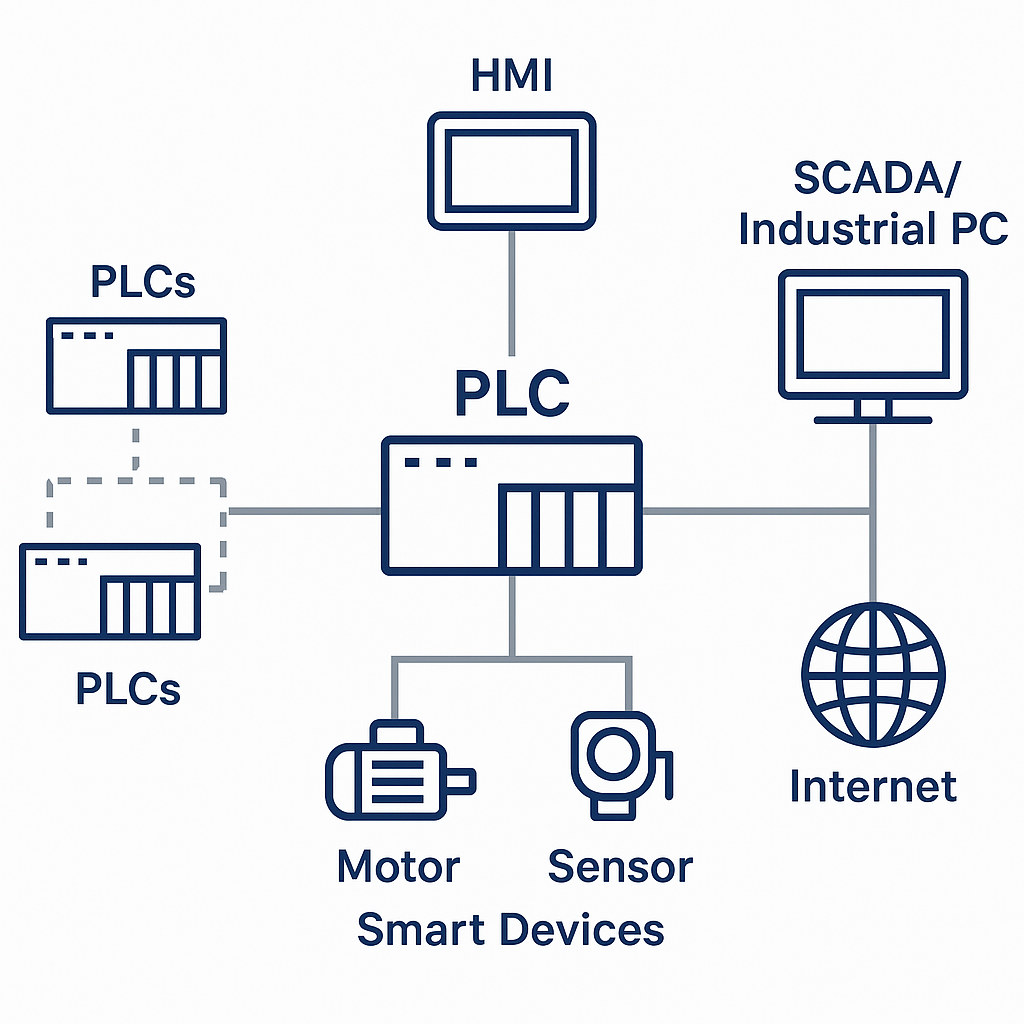

🧰 How Do You Interact with a PLC Without HMI?

When no HMI or SCADA is available, engineers rely on:

PLC programming software (e.g., TIA Portal, RSLogix, GX Works) via laptop

LED indicators and push buttons wired to digital I/Os

Custom PC interfaces (basic software using Modbus/TCP, for instance)

Physical documentation and manual maintenance logs

In such setups, maintenance staff need to be more familiar with the logic and tools.

💡 Final Thoughts

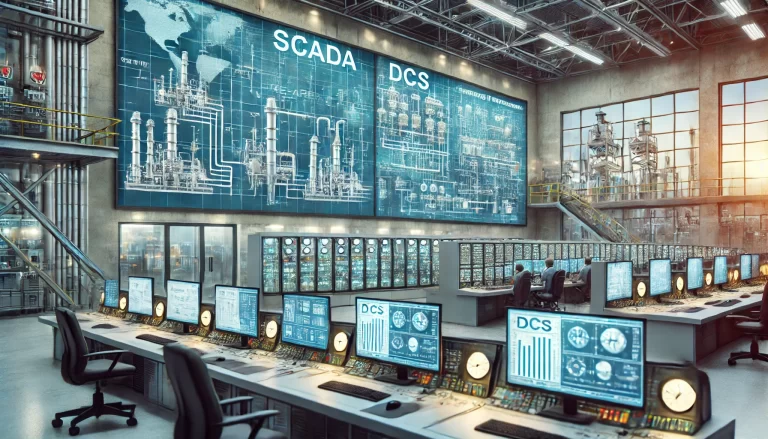

HMI and SCADA systems add significant value by making control systems user-friendly, maintainable, and scalable. However, they are not required for a PLC to run.

A PLC can operate silently and reliably in the background — but without an HMI or SCADA, the human eye becomes blind to what’s happening.

Designers should evaluate the complexity, required interactivity, and budget before deciding whether to include a user interface.