In industrial automation and safety-critical systems, ensuring the integrity of Safety Instrumented Systems (SIS) is crucial. The role of SIS in an industrial environment is to mitigate risks and initiate protective actions independently from regular operational control systems, specifically the Distributed Control System (DCS). A common question in this domain is whether a DCS can send direct open/close commands to an SIS for controlling the Safety Instrumented Function (SIF) in a process that involves field shutdown valves. Below, we examine this in detail.

1. Purpose of SIS and DCS in Process Control

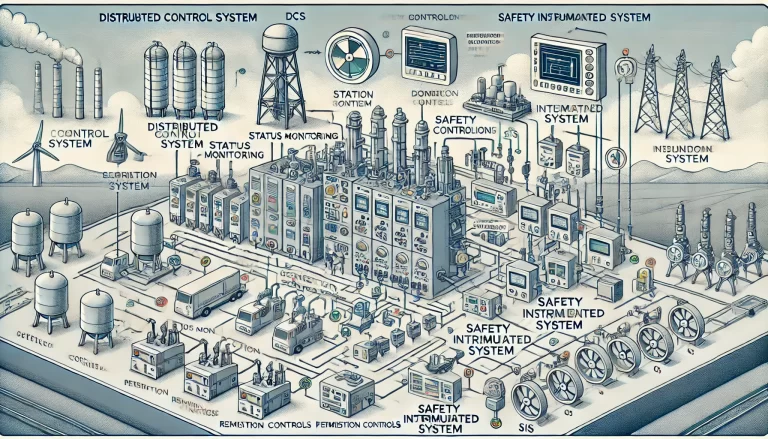

- SIS (Safety Instrumented System): The primary function of an SIS is to detect and respond to abnormal conditions that pose a safety risk, ensuring that the system enters a safe state. An SIS is designed to execute safety functions independently to maintain integrity and reliability, often operating as a failsafe system.

- DCS (Distributed Control System): The DCS is used to control and monitor the process under normal operating conditions. It optimizes the process variables, such as pressure, temperature, and flow, to achieve efficient production while maintaining product quality and regulatory compliance.

The independence of SIS from DCS is a fundamental principle in safety systems design, as it minimizes the chance that an error or failure in the DCS will compromise the safety functions managed by the SIS.

2. Interfacing Between DCS and SIS

While it is technically possible for a DCS to interface with an SIS, it is not generally advisable to allow direct control commands from DCS to SIS for Safety Instrumented Functions (SIF). This is because doing so could compromise the integrity of the SIS by allowing regular operational control signals to impact the execution of safety-critical functions.

However, some communication is often permitted between DCS and SIS, such as:

- Status Monitoring: The DCS can read the status of the SIS, such as the open or closed position of valves, the state of alarms, and other indicators of process health.

- Operator Notification: SIS can notify the DCS of critical events or conditions, enabling the operator to take further action if necessary.

Allowing DCS to issue commands directly to SIS can be risky because it could create vulnerabilities in the safety system. It also violates the segregation principle outlined in standards like IEC 61511, which mandates the independence of safety layers to avoid common-cause failures that could lead to a hazardous condition.

3. Designing DCS-to-SIS Interfaces with Functional Safety in Mind

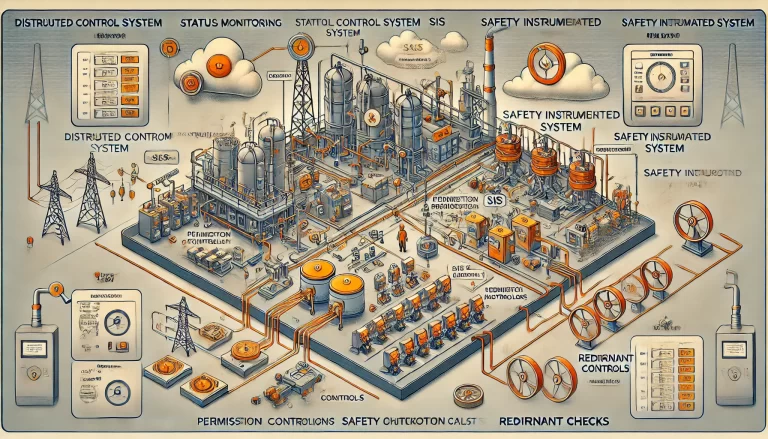

If a DCS-to-SIS control link is necessary, several safety measures must be put in place to meet international safety standards, particularly IEC 61508 and IEC 61511. These include:

- Strict Permission Controls: The SIS should not accept direct commands from the DCS unless there is a clear need, such as during maintenance or specific operational overrides. These permissions should be controlled tightly with documented procedures and management of change (MOC) protocols.

- Intermediate Verification: Instead of a direct DCS command, the DCS could issue a request signal, which the SIS could evaluate according to predefined logic. This means the SIS itself retains final control and can ignore the command if conditions are unsafe.

- Redundant Checks and Interlocks: Multiple layers of verification, including diagnostic checks, can be implemented to ensure that any command reaching the SIS for SIF operations is valid, authorized, and safe.

- Alarm and Event Logging: Any direct communication from DCS to SIS for control should be logged in detail, creating a traceable record for auditing purposes. This allows verification that such commands are only issued in permissible scenarios, thus maintaining the integrity of the SIS.

4. Risk and Compliance Considerations

Allowing DCS to control SIS functions introduces risks, as it goes against the safety philosophy of separation. Before implementing any such configuration, a thorough risk assessment is essential to justify the design and establish risk mitigation strategies. Key steps include:

- Risk Analysis and HAZOP: Conduct a hazard and operability study (HAZOP) to understand the risks of allowing DCS commands to influence SIS actions. This analysis identifies potential failures and ensures the design aligns with acceptable risk levels.

- Functional Safety Assessment: Perform a Functional Safety Assessment (FSA) to determine whether the modified design meets safety standards like IEC 61511.

- Compliance with Safety Integrity Level (SIL) Requirements: If the DCS-to-SIS interface impacts a Safety Instrumented Function, the system must continue to meet the required Safety Integrity Level (SIL) for that function, ensuring reliability under failure conditions.

5. Conclusion

While some industries may implement DCS-to-SIS command configurations with safeguards in place, direct command links between DCS and SIS are generally discouraged. Instead, systems should adhere to strict independence principles to protect the safety functions provided by SIS. Only under controlled, justified, and thoroughly risk-assessed conditions should a DCS be allowed to influence SIS operations directly, and even then, the SIS must retain authority to override such commands based on safety logic.

By adhering to functional safety principles and regulatory standards, industrial facilities can ensure that DCS and SIS systems function together harmoniously without compromising the integrity of safety protections.