In high-risk environments such as petrochemical plants, gas stations, tunnels, and laboratories, toxic and combustible gas detectors serve as the first line of defense for both personnel safety and the stable operation of equipment.

So, do these detectors require verification or calibration? What is the difference between these two processes? Who is responsible for them, and how often should they be done? This article will clarify these points.

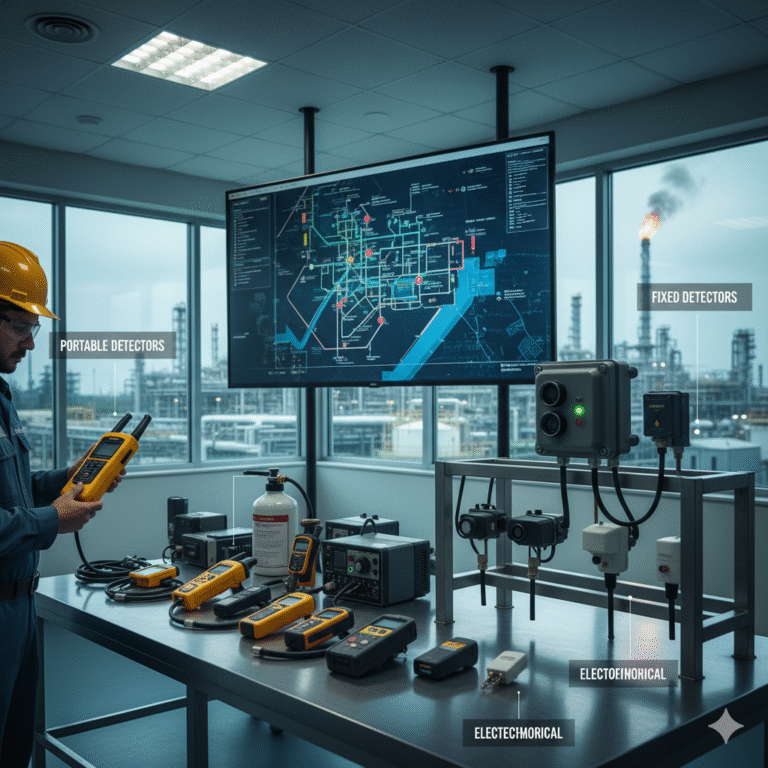

What is a Gas Detector?

A gas detector is an instrument used to detect the concentration of toxic or combustible gases in the air.

Types of Gas Detectors:

Portable (for inspection purposes)

Fixed (for online monitoring)

Detection Principles include:

Catalytic combustion (for combustible gases)

Electrochemical (for toxic gases)

Infrared/thermal conductivity

Semiconductor

Main Function:

Gas detectors alert users with sound and light warnings when the concentration of detected gases reaches a preset threshold, signaling potential danger.

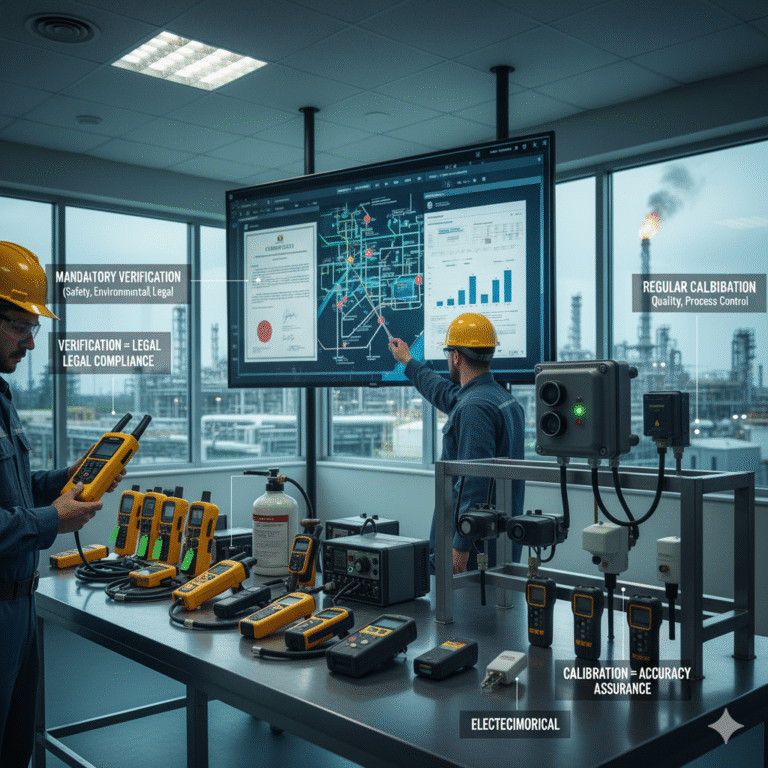

Difference Between Verification and Calibration

In equipment management, “verification” and “calibration” are often confused, but they have different meanings:

| Criteria | Verification | Calibration |

|---|---|---|

| Definition | Performed by national or authorized measurement bodies to confirm compliance with national standards. | Comparing and adjusting the instrument’s measurement to ensure accuracy. |

| Nature | Mandatory, legal requirement. | Technical, quality control. |

| Documents | Verification certificate (legally binding). | Calibration report (technical/quality document). |

| Common Use Cases | Used for safety, environmental monitoring, and law enforcement. | Used internally by companies for monitoring and process control. |

“Verification = Legal Compliance”

“Calibration = Accuracy Assurance”

Which Detectors Need to Be Verified?

According to the Measurement Law of the People’s Republic of China and its implementation regulations:

All measurement instruments listed in the mandatory verification directory must undergo verification.

For gas detectors, the criteria are as follows:

Detectors used for safety, environmental monitoring, and occupational health typically fall under mandatory verification.

For example, JJG693-2011 (Verification Procedures for Combustible Gas Detectors) applies to combustible gas detectors used in non-mining environments. Similarly, JJG915-2008 (Verification Procedures for Carbon Monoxide Detectors) remains valid.

While the 2020 update to the Compulsory Measurement Instrument Directory removed some gas detectors from the mandatory verification list, local safety authorities still emphasize regular verification or calibration as per the relevant regulations.

Therefore, fixed gas detection systems used for safety protection purposes should generally be treated as “must be verified” equipment.

When is Calibration Sufficient?

If the gas detector is for internal company use and does not fall under mandatory measurement, such as portable inspection devices or process monitoring instruments, only regular calibration is required.

The typical calibration period is every 6 to 12 months, but this can be adjusted based on the manufacturer’s recommendations or the company’s quality management system requirements.

Common Verification/Calibration Processes and Recommended Periodicity

Process Overview:

Visual and Functional Inspection: Check the display, alarms, buttons, wiring, etc.

Zero Point Calibration: Adjust the zero point in clean air or a standard gas.

Range Calibration: Use standard gases to check and adjust the detector’s reading for different concentrations.

Response and Recovery Time Testing.

Signal Output Verification: Ensure output signal is accurate and properly recorded.

Recommended Periodicity:

For Fixed Combustible Gas Detectors:

According to JJG693-2011, the verification cycle should not exceed one year.

For Toxic Gas Detectors:

Industry practice suggests verifying at least once per year. Calibration should be repeated immediately after significant maintenance, sensor replacements, or incidents such as alarms exceeding limits.

Legal Responsibilities and Company Management Requirements

According to the Measurement Law of the People’s Republic of China, any mandatory measurement instrument must be verified according to the law.

Failure to verify or calibrate a gas detector used for safety purposes may result in enforcement actions, including suspension of use, correction orders, and, in severe cases, legal penalties.

Companies should establish a complete equipment log, verification/calibration schedules, certificate storage, and exception record systems, all integrated into safety management frameworks such as ISO 45001 audits.

Common Misunderstandings and Correct Practices

“New equipment doesn’t need verification.”

Reality: A certificate of compliance from the manufacturer does not equal a legal verification certificate. Verification is required before the equipment is used.

“As long as the alarm works, the device is fine.”

Reality: The alarm may function properly, but the readings could still be inaccurate. Calibration or verification is necessary to ensure accuracy.

“Verification once is valid forever.”

Reality: Most detectors have an annual verification cycle. It must be repeated as per the schedule.

“Portable detectors don’t need calibration.”

Reality: All detectors, especially portable ones, require periodic calibration as sensor drift occurs over time.

Future Trends: Towards Smart Technology

Smart self-calibrating sensors are emerging, featuring automatic zero-point and drift correction functions to ensure long-term stability. Cloud-based monitoring systems can track verification and calibration statuses in real time and issue alerts in case of abnormalities, improving maintenance efficiency. Additionally, AI-driven predictive maintenance can forecast sensor lifespan and perform “on-demand” calibration based on real-time data, reducing unexpected downtime. Modular sensor designs also minimize maintenance time, enhancing on-site management efficiency.

Conclusion

If a gas detector is used for safety protection, environmental monitoring, or occupational health, it should be considered a “must-verify” device. For devices used in internal inspections or process control, regular calibration is necessary to ensure measurement accuracy.

Verification emphasizes compliance, while calibration ensures precision — both are indispensable. Companies should integrate verification/calibration processes into their safety management systems, ensuring that they are traceable, documented, and performed regularly.