Cable laying standards are essential to ensure the safety, stability, and longevity of cable systems in industrial and infrastructure projects. This guide outlines key procedures and technical considerations, covering pre-installation checks, installation in various environments, cable fixing and spacing, joint and terminal production, and safety precautions.

1. Pre-Installation Preparation

1.1 Cable Inspection

Visual Check: Ensure the outer sheath is free from damage, dents, or deformation. Confirm that end caps are securely sealed to prevent moisture ingress.

Specification Verification: Check model, conductor size, core count, and rated voltage against design documents.

Insulation Resistance Test: Use a megohmmeter to confirm insulation resistance:

For cables rated ≤1kV: ≥10 MΩ

For 10kV cables: ≥400 MΩ

Record results for documentation.

1.2 Route Planning

Site Survey: Identify obstacles like pipelines or buildings; avoid areas with heat or corrosive substances.

Obstacle Clearance: Remove construction debris and plan bypasses or protections.

Length Allowance: Allow extra length at joints, terminals, and bends.

2. Laying Requirements for Different Environments

2.1 Direct Burial

Burial Depth: Not less than 0.7m (1m in farmland); below frost line.

Layering:

100mm of fine sand/soil above and below cable

Cover with concrete slab or brick (extend 50mm beyond cable sides)

Markers: Place at every 50–100m, bends, joints, and building entries.

2.2 Cable Trenches

Dimensions: Depth ≥600mm, with a 0.5% drainage slope.

Supports:

Hot-dip galvanized steel brackets

Spacing:

Horizontal: ≤1m (power), ≤0.8m (control)

Vertical: ≤1.5m (power), ≤1m (control)

Arrangement:

Separate high- and low-voltage

Power above, control below

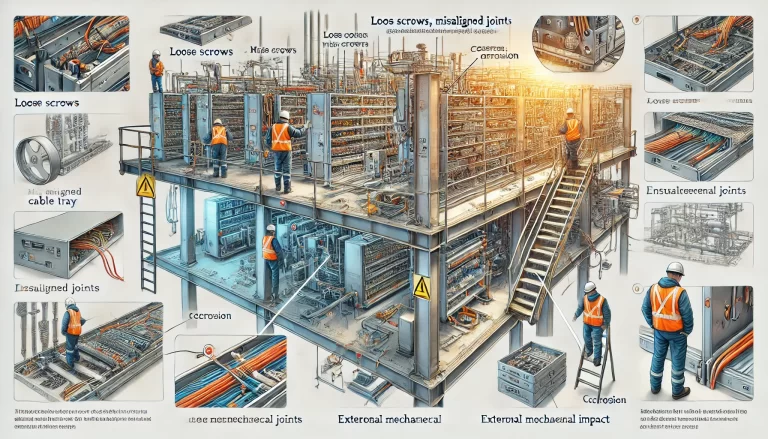

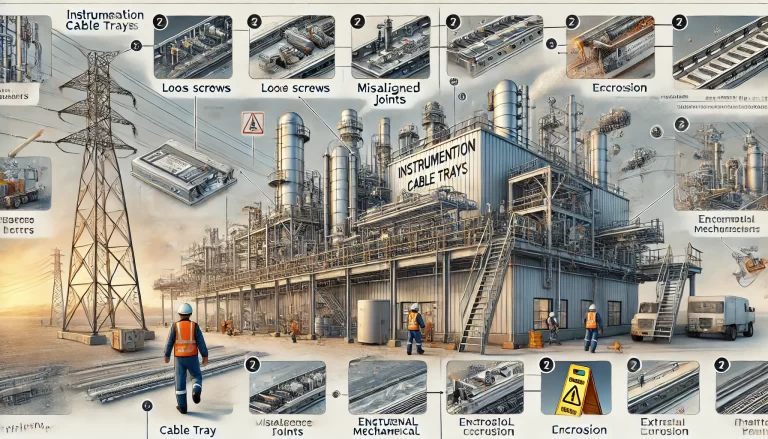

2.3 Cable Trays

Tray Selection:

Ladder, perforated, or solid types

Anti-corrosive materials for harsh environments

Filling Ratio:

≤40% for power cables

≤50% for control cables

Installation:

Firmly fixed, aligned

Use special connectors

Tray bends must match cable bending radius

Layered Laying:

Arrange by voltage and function

3. Cable Fixing and Spacing

3.1 Fixing

Method: Use nylon ties or clamps; do not damage sheath.

Spacing:

Vertical or ≥45° tilt: every 2m

Horizontal ends, joints, bends: must be fixed

Horizontal laying:

Power: every 5–10m

Control: every 8–10m

3.2 Spacing Between Cables

Parallel Laying:

≤1kV power: ≥35mm (not less than cable diameter)

1kV power: ≥250mm

Power vs Control: ≥150mm

Crossing:

Maintain ≥250mm clearance within 1m each side of crossing

Use sleeves or protective devices if clearance is limited

4. Cable Termination and Joint Production

4.1 Production Requirements

Conditions: Dry, clean, well-ventilated; ambient temp >5°C

Procedure:

Follow product manual and standards

Carefully strip layers without damaging conductors

Use correct termination method (crimping, welding)

Seal with matching insulation materials

Appearance: Smooth, bubble-free, wrinkle-free, adequate thickness

4.2 Testing and Inspection

Insulation Resistance: Retest after completion

Optional Tests: Dielectric strength, partial discharge

Appearance Check: Label accuracy, sealing integrity

5. Safety Precautions

5.1 Electrical Safety

Ensure power is off

Post “Do Not Energize” signs

Use insulated tools and wear PPE

Assign supervisor in live areas

5.2 Fire and Explosion Protection

Use flameproof cables where needed

Ban open flames and smoking

Provide extinguishers

5.3 Mechanical Damage Prevention

Avoid dragging or overbending

Use rollers or sleeves in narrow passages

Adjust pulling speed and force with cable laying machines