Instrument technicians play a vital role in ensuring the proper operation of industrial systems. To become proficient in this field, the foundation lies in conducting thorough and systematic routine inspections. This guide details the essential steps, considerations, and best practices for effective inspection and maintenance.

1. Establish a Systematic Routine

Instrument technicians typically oversee specific areas or systems. A systematic approach ensures no equipment is overlooked.

Key Practices:

- Plan Efficient Routes: Determine optimal inspection paths based on the layout and distribution of instruments. A typical schedule involves inspections every two hours.

- Gather Context: Before starting inspections, consult with operators about the current operational status of the instruments. This provides context for any anomalies observed.

- Report and Escalate: Address minor issues immediately. For complex problems, promptly escalate to the workshop or management to prevent disruptions.

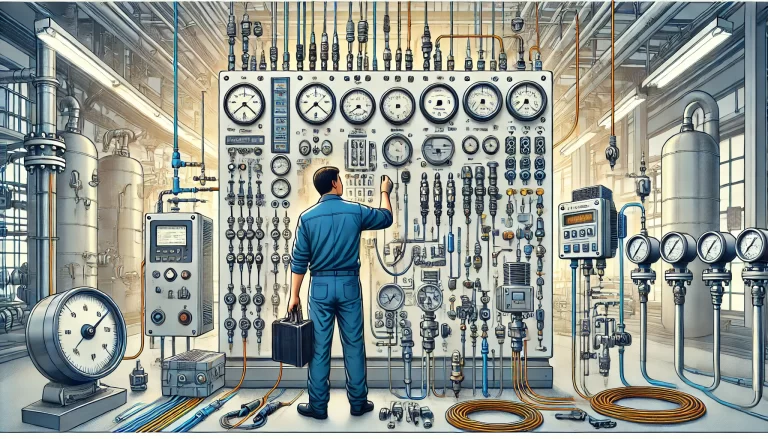

2. Core Inspection Tasks

Daily inspections focus on the following areas:

a. Instrument Readings and Consistency

- Verify that field instrument readings (primary instruments) match those displayed in the control room (secondary instruments).

- Cross-check regulator outputs with actuator valve positions. Inconsistencies require immediate recalibration.

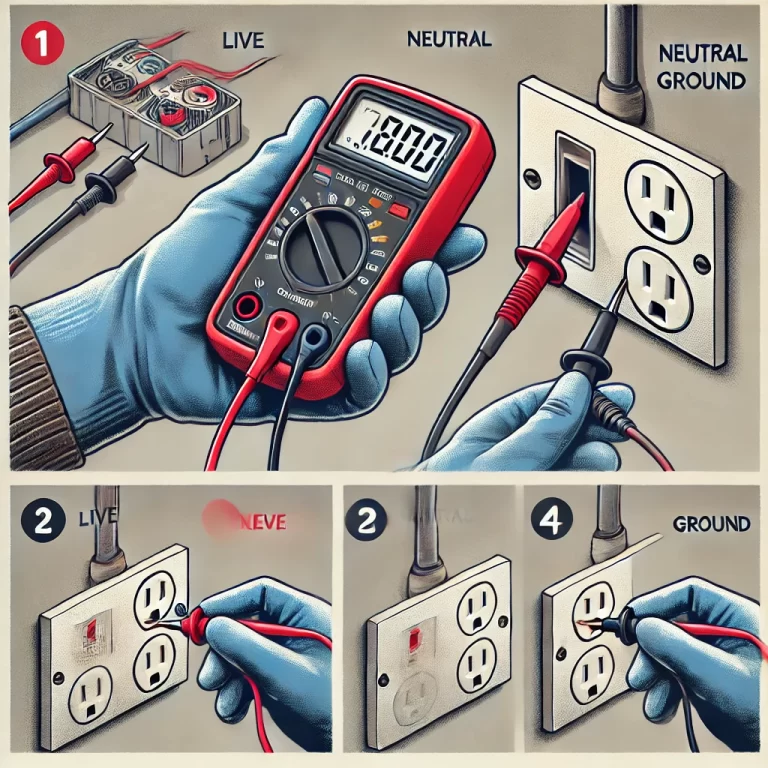

b. Power and Utility Supplies

- Check power supplies (AC 220V or DC 24V) for stability.

- Inspect air or oil supplies for actuators. Confirm that supply pipes are secure and feedback mechanisms, such as positioners, are functioning properly.

c. Seasonal Considerations

Summer:

- Inspect waterproofing measures for field instruments, particularly around connection points and signal cable conduits.

- Address any water ingress to prevent signal disruptions or equipment damage.

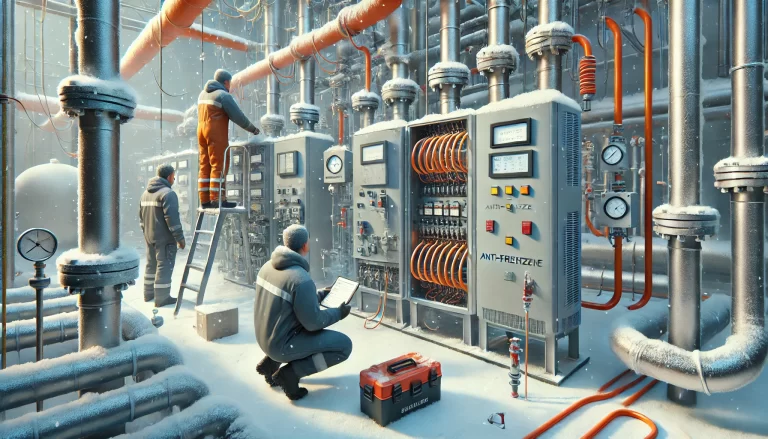

Winter:

- Pay special attention to insulation and heat tracing systems to protect instruments from freezing.

- Inspect flowmeters (e.g., vortex, electromagnetic, turbine) and transmitters (e.g., differential pressure and level) for proper insulation. Look for signs of damage or saturation in insulation materials.

- Heat tracing (electric or steam) systems require monitoring to ensure consistent operation:

- Electric Tracing: Confirm voltage levels are within acceptable ranges.

- Steam Tracing: Adjust steam flow based on temperature fluctuations to avoid overheating or underheating. Continuous steam discharge may indicate excessive flow, while no discharge could signal insufficient flow.

d. Corrosion and Damage

- Inspect instrument bodies, fittings, and connections for damage or corrosion, particularly in areas with harsh chemical environments (e.g., sulfur recovery units or high-pressure systems).

- Ensure all components meet safety standards to minimize risks of failure.

e. Leak Detection

- Check for leaks at connections and seals, such as union joints and valve packing.

- Pay special attention to systems under thermal stress, where expansion and contraction can compromise seals.

f. Control Room Observations

- Monitor control panels, servers, and UPS systems for normal operation. Look for warning indicators or alarms that may signal underlying issues.

3. Best Practices for Special Scenarios

- For instruments using steam tracing during winter, avoid excessive steam flow to prevent material phase changes in the process fluid. Overheating low-boiling-point substances could lead to vaporization, causing inaccurate readings or unstable outputs.

- Use drain traps on steam lines to manage condensation and adjust flow rates based on ambient temperature changes.

4. Case Study: Addressing a Typical Issue

During one winter inspection, a technician observed inconsistent pressure readings from a differential pressure transmitter. Investigation revealed condensation freezing within the impulse line. The issue was resolved by repairing damaged insulation and fine-tuning the steam tracing system. This quick action prevented downtime and ensured accurate measurements.

5. Conclusion

The role of an instrument technician demands attention to detail, technical acumen, and a proactive attitude. By mastering the art of inspections, you lay the groundwork for maintaining safe, efficient, and reliable operations.