Automation has revolutionized industries by streamlining processes, reducing errors, and minimizing the need for human intervention. As technology continues to evolve, automation engineering plays a vital role in increasing productivity, improving quality, and reducing operational costs. In this article, we’ll explore key automation engineering methods and how they contribute to enhancing efficiency and performance across different sectors.

1. Process Automation

Process automation refers to the use of technology to perform routine, repetitive tasks without human intervention. In industries such as manufacturing, healthcare, finance, and customer service, process automation has been instrumental in optimizing workflows.

Robotic Process Automation (RPA): RPA involves deploying software robots to automate repetitive tasks such as data entry, file transfers, and generating reports. By eliminating manual processes, RPA reduces errors and increases the speed of task completion. It’s widely used in industries like banking for handling customer inquiries, processing loan applications, and compliance checks.

Business Process Management (BPM): BPM tools help organizations streamline and automate end-to-end business processes. These tools map out complex workflows and ensure that each step is automatically triggered upon completion of the previous one. BPM improves transparency, ensures compliance, and reduces delays, especially in administrative-heavy fields like human resources and supply chain management.

2. Continuous Integration and Continuous Delivery (CI/CD)

In software development, CI/CD practices are essential for automating the process of integrating code, running tests, and deploying applications. CI/CD pipelines help teams deliver software more efficiently, with fewer bugs and faster time to market.

Continuous Integration (CI): CI involves automatically integrating code changes into a shared repository several times a day. Each integration is verified by automated tests, ensuring that code changes do not introduce errors or conflicts. This approach enables developers to identify and resolve issues early in the development cycle.

Continuous Delivery (CD): After successful integration, CD ensures that the software can be deployed to production at any time. With CD, the deployment process is automated, and every change passes through rigorous testing, reducing the risk of deploying unstable software. CI/CD pipelines are supported by tools like Jenkins, GitLab CI, and CircleCI, which help automate tasks like building, testing, and deployment.

3. DevOps and Infrastructure Automation

DevOps practices have reshaped how development and operations teams collaborate to deliver software. Automation is central to DevOps, enabling teams to scale operations and maintain high performance in distributed environments.

Infrastructure as Code (IaC): IaC allows teams to automate the management and provisioning of infrastructure, such as servers, databases, and networks. Tools like Terraform, Ansible, and AWS CloudFormation enable engineers to define infrastructure configurations in code, ensuring consistency, repeatability, and version control. IaC eliminates manual errors and reduces the time spent configuring and managing environments, making it easier to scale infrastructure on demand.

Automated Monitoring and Alerting: Monitoring tools like Prometheus, Grafana, and Nagios automatically track system performance metrics, such as CPU usage, memory consumption, and network latency. When predefined thresholds are crossed, alerting systems notify engineers of potential issues, allowing them to address problems before they impact users. Automation in monitoring ensures real-time awareness of system health and can even trigger automated responses to correct certain issues, such as restarting services or scaling resources.

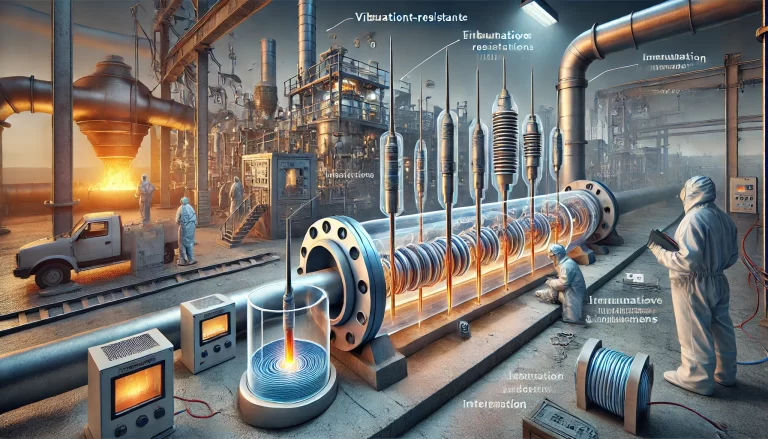

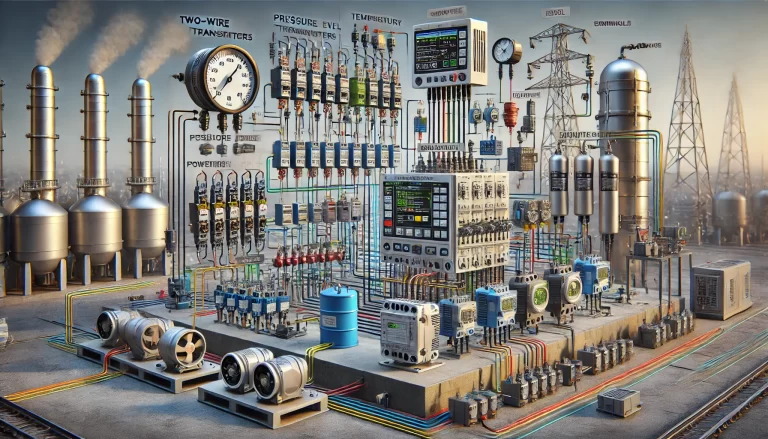

4. Industrial Automation

In manufacturing, industrial automation involves the use of machines, control systems, and information technologies to automate production processes. The goal is to increase efficiency, safety, and consistency, while reducing the reliance on manual labor.

Programmable Logic Controllers (PLCs) and SCADA Systems: PLCs are digital computers used to control industrial machines and processes. They automate tasks such as assembly line production, material handling, and quality control. Supervisory Control and Data Acquisition (SCADA) systems monitor and control industrial processes in real-time, providing valuable data for optimization. Together, PLCs and SCADA systems help industries like automotive, chemical, and food processing maintain high levels of efficiency.

Robotics and Smart Manufacturing: Robotics has transformed industries by automating complex, repetitive tasks. Robotic arms and automated guided vehicles (AGVs) are widely used in warehouses and factories for tasks such as packaging, welding, and product assembly. When combined with smart manufacturing technologies such as IoT sensors and AI, robots can optimize production lines, detect potential faults, and predict maintenance needs.

5. Machine Learning and AI for Process Optimization

Automation is increasingly powered by machine learning (ML) and artificial intelligence (AI). These technologies allow systems to analyze vast amounts of data, make decisions, and optimize processes without human intervention.

Predictive Maintenance: In industries like manufacturing and transportation, AI-driven predictive maintenance systems use data from IoT sensors to predict when equipment is likely to fail. By automatically analyzing data such as temperature, vibration, and pressure, these systems can schedule maintenance before a breakdown occurs, reducing downtime and repair costs.

Intelligent Scheduling and Optimization: AI algorithms can be used to automate complex scheduling tasks, such as optimizing production schedules or workforce management. In supply chain management, AI optimizes logistics routes, reduces lead times, and improves inventory management. These automation techniques lead to better resource allocation and cost savings.

6. Project Management Automation

Managing projects involves tracking progress, assigning tasks, and ensuring deadlines are met. Automation tools in project management allow teams to stay organized and focused on high-priority work.

Agile Project Management Tools: Platforms like Jira, Trello, and Asana automate project tracking, task management, and team collaboration. These tools integrate with other software to automatically update task statuses, send notifications, and generate reports. By automating administrative tasks, project managers can focus on decision-making and strategy.

Automated Document Generation and Reporting: Automated tools can generate reports, project summaries, and documentation based on real-time data. This reduces the time and effort spent on manual reporting and ensures that information is always up to date.

7. Smart Traffic and Vehicle Automation

Automation also plays a crucial role in transportation. Smart traffic management systems and vehicle automation technologies improve road safety, optimize traffic flow, and enhance the driving experience.

Smart Traffic Systems: These systems use sensors, cameras, and AI to monitor traffic conditions and control traffic signals. Automated traffic systems can adjust signal timings in real-time to reduce congestion, prioritize emergency vehicles, and optimize the flow of traffic.

Autonomous Vehicles: Self-driving cars represent a major leap in automation. Autonomous vehicles use AI, sensors, and machine learning algorithms to navigate roads, avoid obstacles, and make driving decisions without human input. The automation of driving tasks holds the potential to reduce accidents, enhance fuel efficiency, and improve traffic management.

Conclusion

Automation engineering continues to be a critical factor in the growth and success of modern industries. By implementing process automation, CI/CD pipelines, DevOps practices, and industrial automation techniques, organizations can significantly enhance their operational efficiency and performance. As AI, machine learning, and robotics technologies evolve, the future of automation promises even greater advancements that will drive innovation and transformation across sectors.