1. Introduction

In industrial piping and instrumentation, thread compatibility is crucial for ensuring proper mechanical connection and sealing. Two commonly encountered thread types are PF and G threads. Users often ask: Are PF1 1/2″ and G1 1/2A threads identical?

This article will clarify the technical relationship between PF and G threads, explain their minor differences, and guide proper application practices.

2. Origin and Standard Reference

Both PF and G threads are based on the ISO 228-1 standard for parallel (straight) pipe threads.

However, their naming conventions differ depending on regional standards:

PF thread originates from the Japanese JIS B 0202 standard, which fully aligns with ISO 228-1.

G thread comes from British Standard (BS 2779) and the later ISO 228-1.

Despite their different origins, PF and G threads are dimensionally identical for corresponding nominal sizes.

3. Key Features Comparison

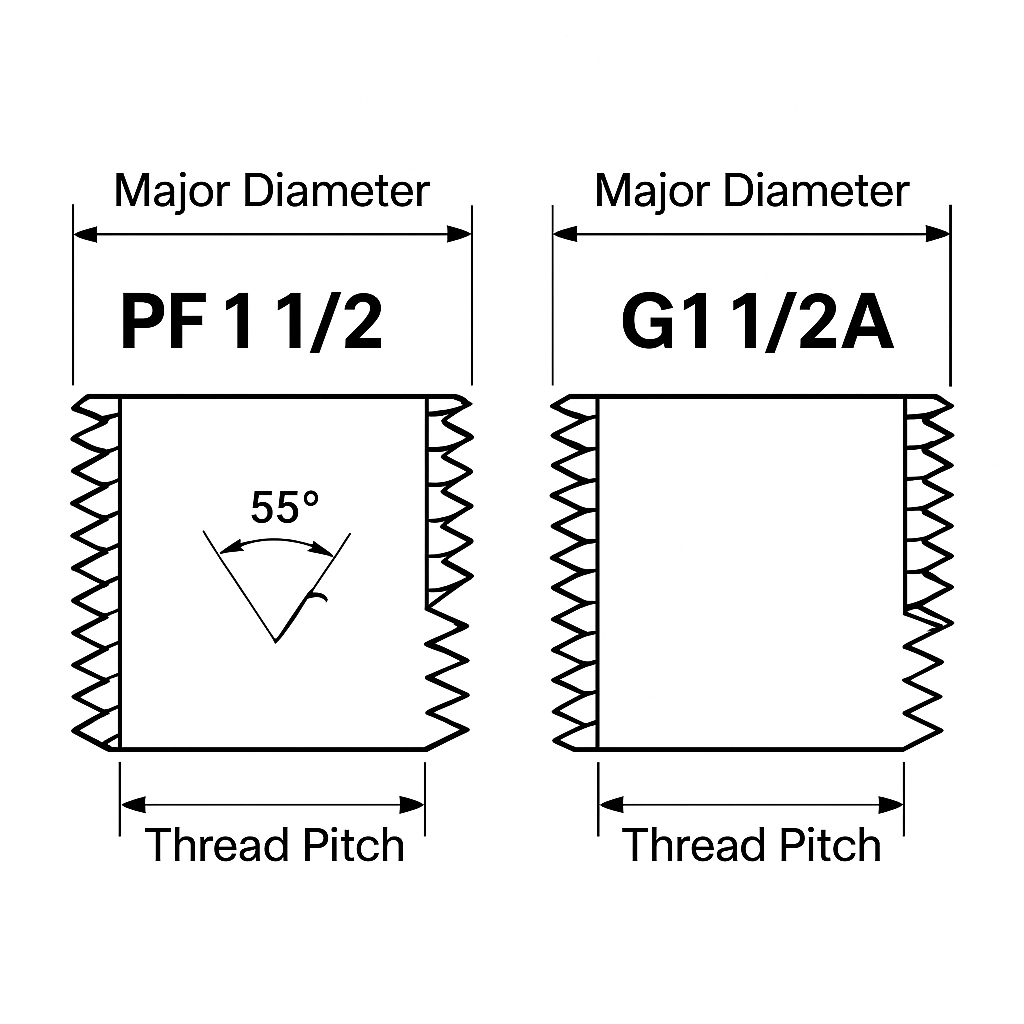

| Feature | PF Thread | G Thread |

|---|---|---|

| Origin | Japan (JIS Standard) | Britain / International (ISO Standard) |

| Thread Type | Parallel (straight) | Parallel (straight) |

| Thread Angle | 55° Whitworth Form | 55° Whitworth Form |

| Sealing Method | Usually requires sealing tape or gasket | Typically relies on gasket or O-ring for sealing |

| Precision Grade | Not specified in the name | “A” indicates higher precision grade (tighter tolerances) |

4. Dimensional Equivalence

From a technical dimension perspective, PF1 1/2″ and G1 1/2A share the same:

Major (Outer) Diameter: Approx. 47.803 mm

Thread Pitch: 1.814 mm

Thread Profile: 55° Whitworth form

Thread Type: Parallel (non-tapered)

Thus, they can be physically connected and interchanged without issue in most applications.

5. The Meaning of “A” in G1 1/2A

The suffix “A” in G1 1/2A indicates precision grade:

“A” Grade: Tighter tolerance for better mechanical fit.

“B” Grade: Standard tolerance.

In practical industrial settings, Grade A is preferred when:

High-quality sealing surfaces are required.

More critical mechanical alignment is needed (e.g., in instrumentation connections).

However, for most general piping and fitting purposes, PF1 1/2″ and G1 1/2A are fully compatible.

6. Application Considerations

While PF and G threads match dimensionally, users should consider the following:

Sealing: Both threads are parallel and do not seal via threads.

Use appropriate sealing methods such as PTFE tape, sealing rings, or bonded O-rings.Pressure Requirements: Always verify whether the sealing method is suitable for the system pressure.

Precision Requirements: For high-precision installations (e.g., sensors, flow meters), using Grade A G-threads or matching PF threads ensures better performance.

7. Conclusion

PF1 1/2″ and G1 1/2A threads are dimensionally identical and interchangeable.

The main difference lies in naming conventions and the precision grade indicator “A” in G threads. In most industrial applications, they can be directly mated without any problem, provided that proper sealing is ensured.

When selecting fittings or designing piping systems, always confirm the sealing method and precision requirements to ensure optimal system reliability.

Tip:

If you frequently deal with different thread standards, maintaining a PF/G Thread Conversion Table would save time and prevent confusion during project design or sales communication.