A Practical Guide to 9 Common On-Site Installation Issues

Flowmeters are indispensable instruments in modern industrial processes. Yet, many measurement inaccuracies, maintenance challenges, or even outright failures are often not due to the meter itself—but rather to improper installation practices.

From insufficient straight pipe lengths for electromagnetic flowmeters, to misaligned filters in rotameters, or incorrectly oriented pressure taps in wedge meters—these seemingly small mistakes can lead to major process deviations.

This article summarizes nine typical installation issues frequently observed in the field, with practical recommendations to help engineers avoid them.

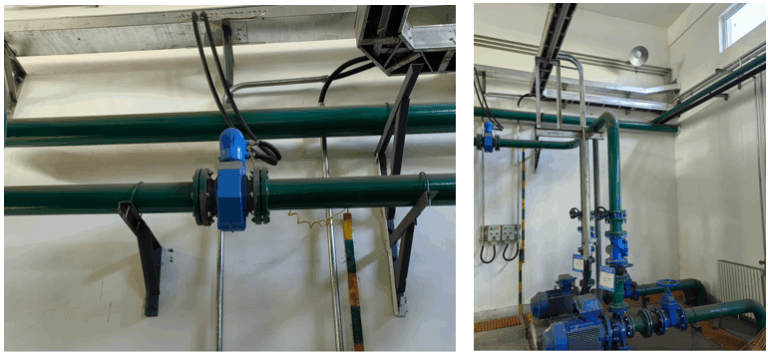

1. Improper Installation Position of Electromagnetic Flowmeters

Electromagnetic flowmeters require a completely filled pipe to ensure accurate measurement.

If the installation point is not properly selected, or if there is insufficient straight pipe length upstream, the meter will suffer from unstable readings.

Recommendation: Place the meter in a location where the pipe is always full and allow for sufficient straight run.

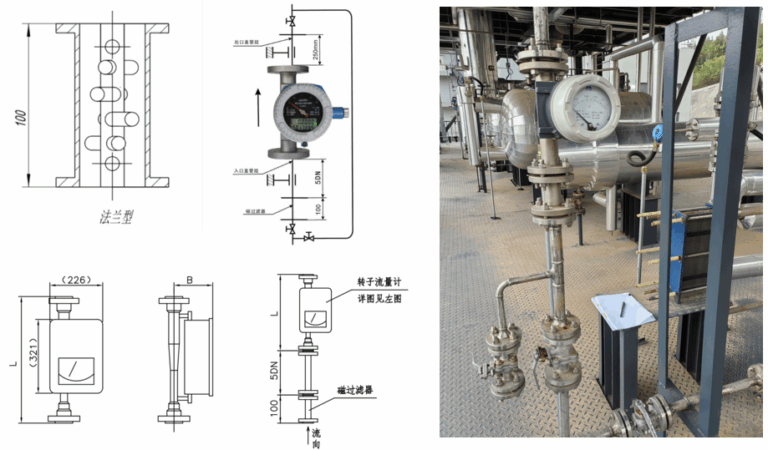

2. Magnetic Filter Misplacement in Rotameters

When a magnetic filter is installed incorrectly (e.g., upstream but counted outside the straight run), the effective straight pipe section is reduced. This can result in distorted flow profiles.

Recommendation: Ensure that the straight run begins after the magnetic filter, not before.

3. Incorrect Orientation of Wedge Flowmeters

Installing a wedge flowmeter with its pressure tap facing downward often causes sediment build-up, leading to inaccurate measurements and maintenance difficulties.

Recommendation: Install the pressure tap horizontally or upward and leave enough clearance space for future maintenance.

4. Grounding Requirements for Electromagnetic Flowmeters in Non-Metallic Pipes

Electromagnetic flowmeters require proper grounding to prevent signal instability.

Metallic pipelines: Use built-in grounding electrodes.

Non-metallic or lined pipelines: Install grounding rings to ensure reliable signal reference.

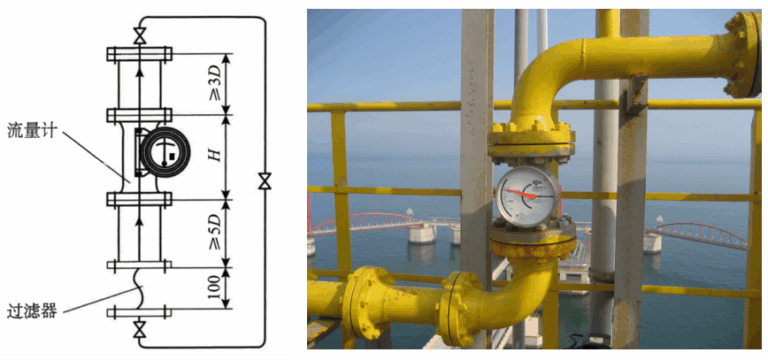

5. Straight Pipe Requirements for Rotameters

Although some datasheets claim rotameters can work without straight runs, in practice:

Upstream: ≥ 5D

Downstream: ≥ 3D

(where D = internal diameter of pipe).Recommendation: Use matching pipe diameters upstream and downstream for stable performance.

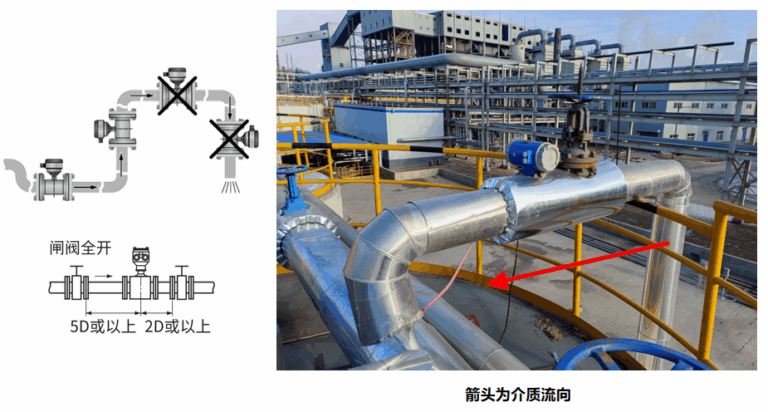

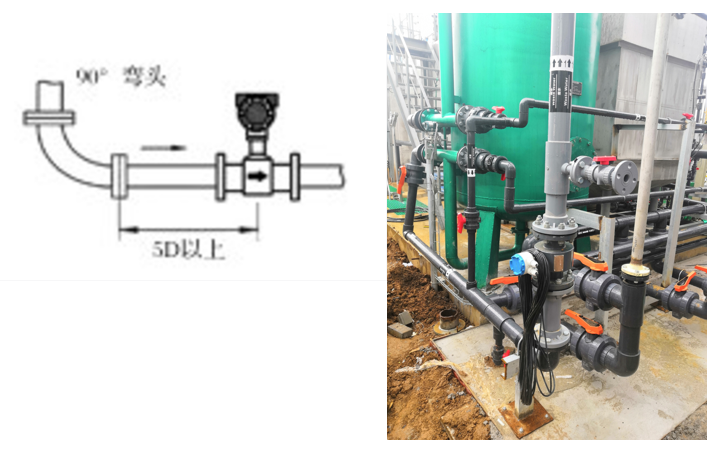

6. Straight Pipe Requirements for Electromagnetic Flowmeters

Electromagnetic flowmeters are sensitive to flow disturbances such as elbows, valves, or tees.

Best practice: Upstream ≥ 10D, downstream ≥ 5D.

Minimum requirement: Upstream ≥ 5D, downstream ≥ 3D.

Tip: Use a flow straightener if space is limited.

7. Vortex Flowmeters for Steam Measurement: Use Remote-Mount Design

When measuring steam, especially in high-temperature or elevated installations, integrated transmitters are impractical.

Recommendation: Use remote (split-type) vortex flowmeters, with converter placed in a safe, accessible location.

Note: Shielded signal cables (e.g., 2-core, max 20 m) should be factory-supplied.

8. Flowmeters Installed in Inaccessible Locations

For flowmeters placed on pipe racks or at high elevations, routine operation and inspection become difficult.

Recommendation: Choose remote-mount designs or relocate instruments to operator-friendly platforms.

9. Orifice Plate Flowmeters: Position of Differential Pressure Transmitters

Incorrect transmitter location increases maintenance risks.

Recommendation: Mount the differential pressure transmitter on a ground platform or accessible area, rather than directly at elevated pipe runs.

📌 Conclusion

The accuracy and reliability of flow measurement depend not only on the instrument itself but also—crucially—on its installation quality.

By avoiding these nine common mistakes, engineers can significantly reduce downtime, improve measurement stability, and extend the service life of flowmeters.

Pro tip: Always refer to the manufacturer’s installation guidelines, and when in doubt, perform a pre-installation review checklist with your engineering team.