In chemical manufacturing, measurement instruments are not only vital tools for precise control of production processes but also serve as crucial safety barriers that protect personnel, equipment, and the environment. Establishing an effective system of measurement instruments can significantly reduce the risk of accidents and ensure sustainable and safe production.

1. The Role of Measurement Instruments

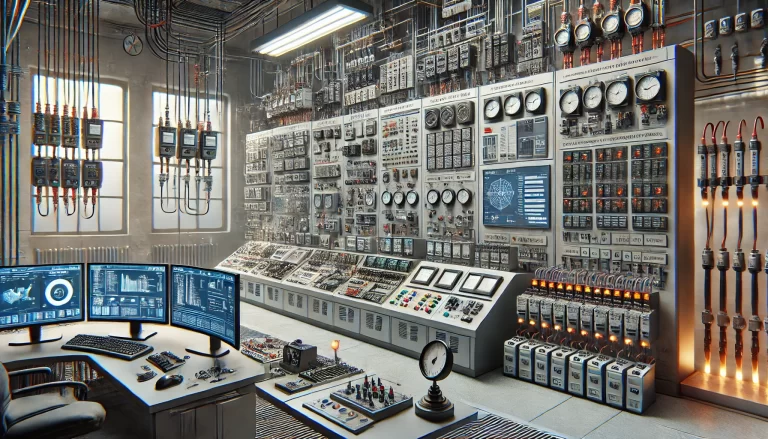

Measurement instruments in chemical plants are primarily used to monitor and control parameters such as temperature, pressure, flow rate, liquid levels, and chemical composition. Accurate monitoring of these parameters is essential to prevent production from spiraling out of control, equipment overload, leaks, and explosions. For example, pressure sensors help detect abnormal pressure buildups, allowing timely interventions to prevent container ruptures. Similarly, temperature sensors ensure that exothermic reactions do not overheat, which could otherwise result in fires or explosions.

2. Types and Functions of Measurement Instruments

Various types of measurement instruments are used in chemical plants, each serving specific functions:

Pressure Gauges and Transmitters: These monitor the pressure within vessels and pipelines to ensure operations remain within safe limits.

Thermometers and Temperature Transmitters: These are used to track reaction temperatures and ensure that chemical reactions occur within safe and optimal ranges.

Flow Meters: These measure the speed and volume of fluids in the system, helping maintain process parameters in line with design specifications.

Level Sensors: These instruments monitor the liquid levels in tanks and reactors to prevent overflow or dry running, both of which can pose serious risks.

Gas Detectors: These detect potentially hazardous gas leaks, such as ammonia, chlorine, or combustible gases, which could lead to fire, explosion, or toxic exposure.

3. Building and Maintaining a Robust Safety System

Measurement instruments must be not only accurate but also reliable and durable, capable of withstanding the demanding conditions of chemical production. To maintain their effectiveness, chemical plants should regularly undertake the following maintenance activities:

Calibration and Testing: Regular calibration ensures that instruments maintain their accuracy. This should be done following manufacturer guidelines and industry standards.

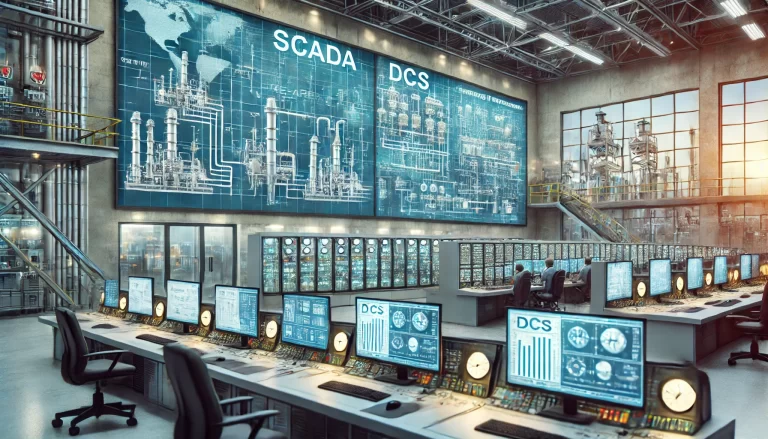

Data Monitoring and Analysis: Utilizing modern digital tools for real-time data collection and analysis helps identify potential anomalies early.

Redundant Design: For critical parameters, multiple instruments should be installed to provide redundancy. This ensures that even if one instrument fails, the system continues to operate safely.

Regular Training: Operators should receive thorough training on the use and emergency handling of measurement instruments. This enhances overall safety awareness and equips personnel to respond effectively in case of incidents.

4. The Future of Digitization and Smart Technologies

The advent of Industrial Internet of Things (IIoT) and artificial intelligence (AI) is continuously enhancing the capabilities of measurement instruments. Smart sensors and automated control systems enable remote monitoring and provide predictive warnings, allowing for proactive maintenance and reducing the likelihood of equipment failure. Moreover, advanced data analytics tools can optimize process workflows, enhancing overall production efficiency.

Conclusion

Measurement instruments play an indispensable role in chemical plants, serving as the backbone of safe and stable operations. By carefully selecting, maintaining, and upgrading these instruments, chemical companies can build a strong safety barrier that protects employees, communities, and the environment.