Ultrasonic level meters are widely used in wastewater treatment plants, especially in scenarios where the medium is relatively simple and not highly complex. The key to selecting ultrasonic level meters for wastewater treatment tanks lies in identifying the standard conditions and the low-complexity medium. Below are the specific applicable scenarios and key considerations:

I. Core Applicable Work Conditions

Municipal / Domestic Wastewater Treatment Tanks

Applicable Scenarios: Bar screen tanks, regulation tanks, aeration tanks, secondary sedimentation tanks, and other conventional treatment units.

Key Conditions: Wastewater primarily consists of organic matter, with low solids content (suspended solids ≤ 10%). The water should not contain large amounts of viscous foam, and the pH should range between 6-9 (weakly acidic or neutral).

Typical Advantages: Meets the general monitoring needs of municipal wastewater treatment (with an accuracy of ±0.5% FS), easy to install and maintain, and offers high cost-performance.

Low-Corrosion Industrial Wastewater Treatment Tanks

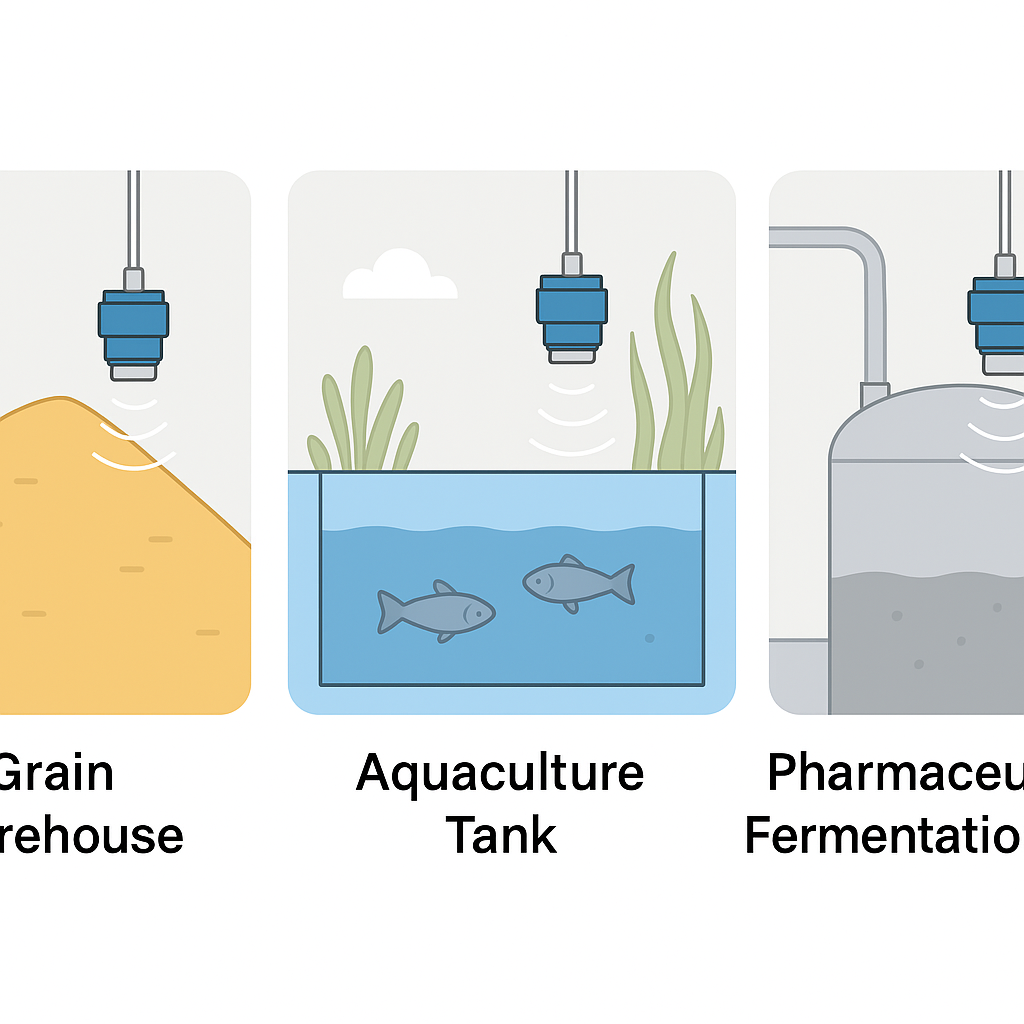

Applicable Scenarios: Lightly polluted wastewater from industries like food processing, pharmaceuticals, and electronics (no strong acids, alkalis, or organic solvents).

Key Conditions: The wastewater should be non-corrosive (pH 5-10) without excessive oil or viscous sediment, and the tank depth should not exceed 15 meters (the range of a standard ultrasonic meter).

Selection Considerations: Choose a standard protection (IP67) model for ordinary conditions. If there is slight floating debris, prioritize models equipped with foam filtering algorithms.

Small to Medium-Sized Outdoor / Indoor Wastewater Tanks

Applicable Scenarios: Small wastewater collection tanks in factory areas, community wastewater treatment stations, or laboratory wastewater tanks.

Key Conditions: Tank depth ≤ 10 meters, ample installation space (unobstructed), and no strong electromagnetic interference (such as from large variable frequency drives or high-voltage equipment).

Special Adaptations: For outdoor environments, choose IP68-rated models, and use a sunshade to prevent direct rainwater exposure on the sensor.

II. Key Applicable Work Parameters

Tank Depth: Preferably between 0.3 and 15 meters (standard ultrasonic meters’ range), for depths exceeding 15 meters, consider using radar-based level meters.

Medium Temperature: -20°C to 80°C (standard models); for high-temperature wastewater tanks, consider customized high-temperature models.

Environmental Conditions: Humidity ≤ 95%, no strong dust, no continuous vibrations, and electromagnetic interference intensity ≤ 3V/m.

Measurement Requirements: Routine level monitoring (no need for high-precision process control), with data transmission via 4-20mA/RS-485.

III. Work Conditions to Approach with Caution or Not Suitable for Ultrasonic Level Meters

High Foam/Viscous Suspended Solids (e.g., Chemical Wastewater Tanks or Sludge Concentration Tanks): Standard ultrasonic meters are prone to measurement errors due to foam reflection interference.

Highly Corrosive Wastewater (pH < 5 or > 10, such as acid or alkaline wastewater tanks): Standard probes may be easily corroded, requiring PTFE-coated probes.

Tank Depth > 15 Meters or High Electromagnetic Interference: Measurement stability may decrease. Radar-based level meters are recommended for such conditions.