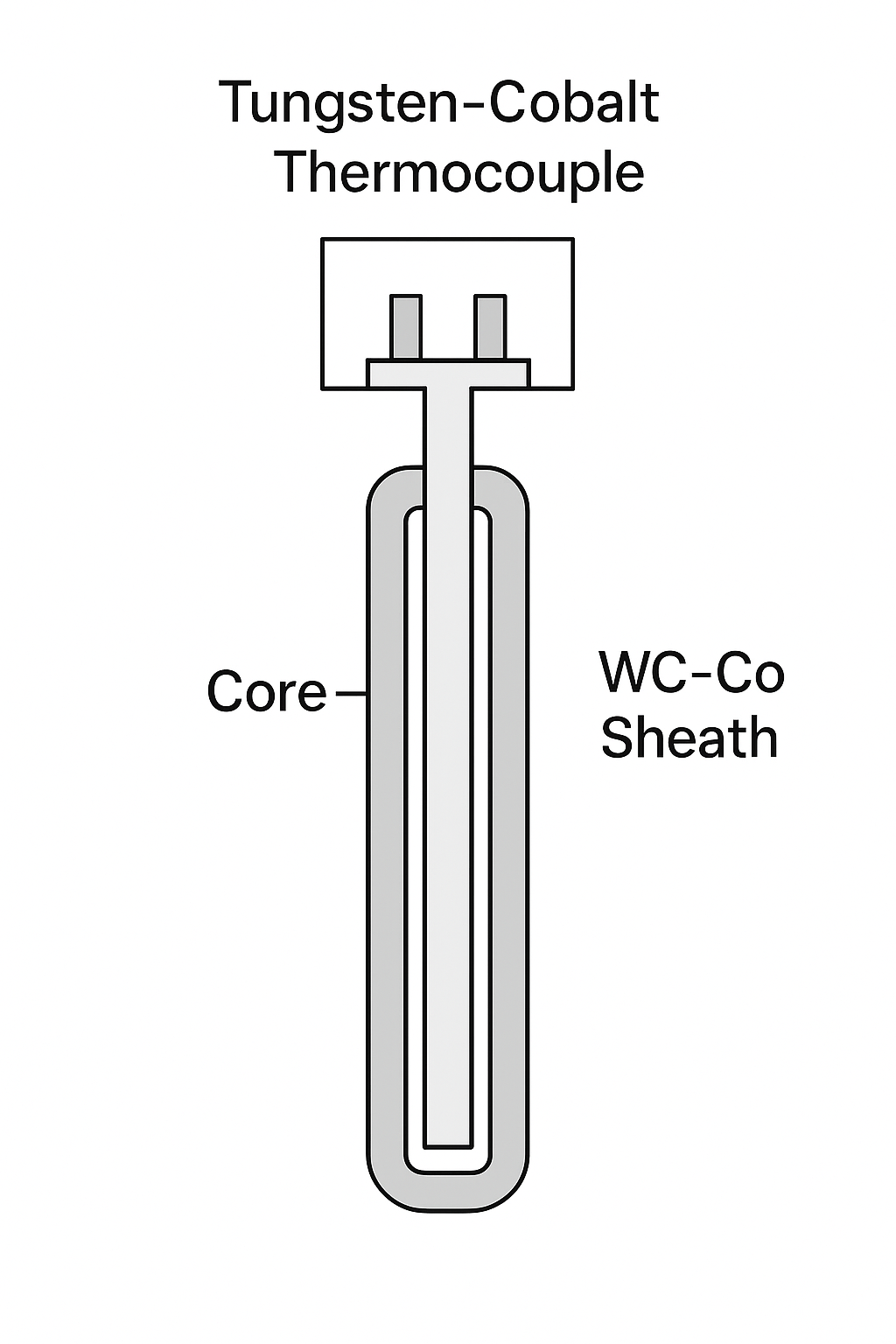

Tungsten-cobalt alloy wear-resistant thermocouples are designed for extreme high-temperature and severe abrasive environments, where hard particles, high-velocity gases, or aggressive material flows cause rapid wear on conventional thermocouples. Their core advantage lies in combining excellent wear resistance with high thermal stability, ensuring accurate temperature measurement and extended service life.

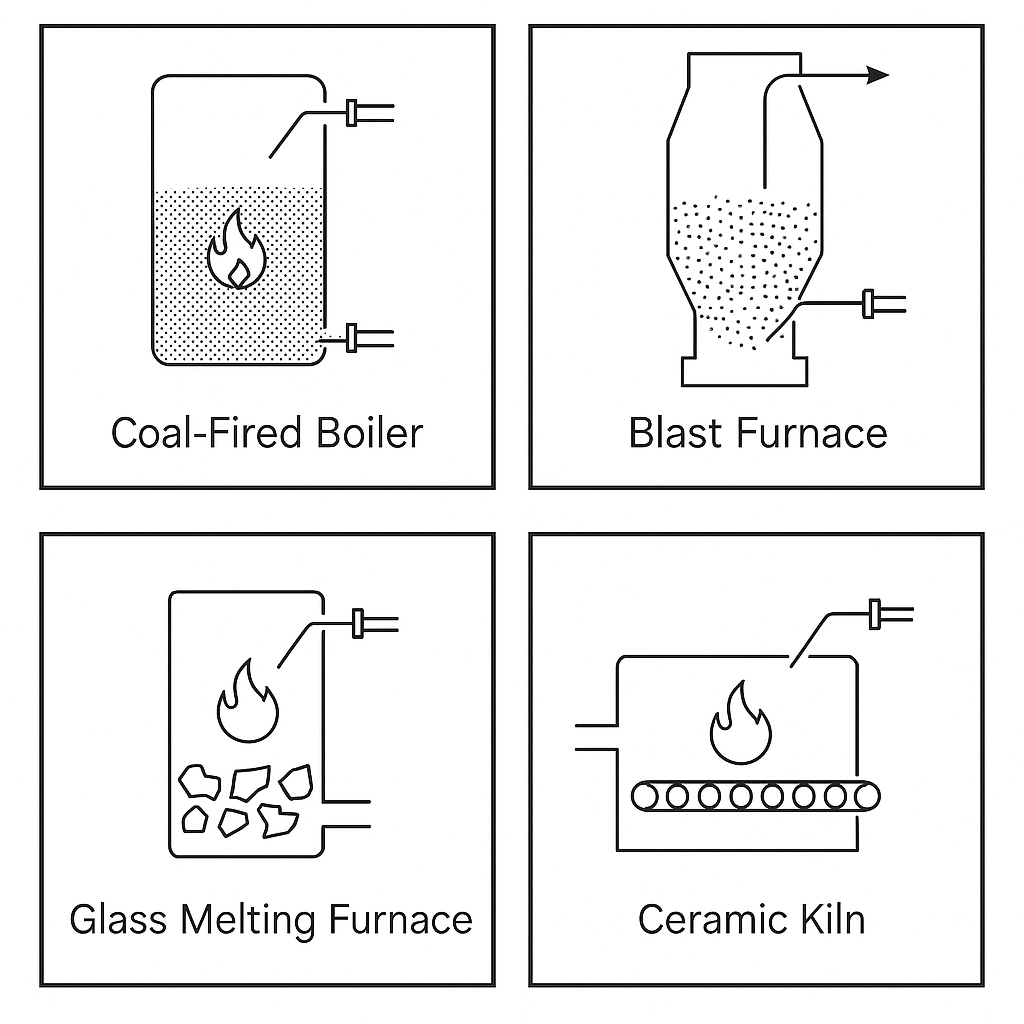

1. Power & Energy Industry

High-temperature flue gas, coal dust, and ash particles in power generation cause intense erosion to temperature sensors. Tungsten-cobalt thermocouples are critical in:

Coal-fired boilers – Furnace outlet, superheater, and economizer areas for measuring flue gas (600–1000 °C) and ash-laden zones.

Fluidized bed boilers – Bed interior and cyclone separator inlets for monitoring fluidized bed materials (coal and limestone particles at 800–900 °C) under continuous particle impact.

Coal powder pipelines – From pulverizer outlet to furnace inlet for measuring air–coal mixture temperature (200–400 °C) while resisting high-velocity particle scouring.

2. Metallurgy & Steel Industry

Harsh contact with ores, slag, and molten metal demands extreme wear resistance:

Blast furnace systems – Hot-blast stove dome and lower furnace body for monitoring hot blast (1000–1200 °C) and descending burden materials.

Sintering machines & pellet kilns – Flue ducts and kiln inlets for measuring roasting temperature (600–1000 °C) of sinter and pellets.

Steel reheating furnaces – Near skid rails and discharge zones for measuring billet surface temperature (800–1300 °C) under dust and hot steel abrasion.

3. Building Materials Industry

Abrasive raw materials like cement clinker and glass batch require robust sensors:

Cement rotary kilns – Kiln inlet/outlet and preheater for measuring clinker temperature (800–1400 °C) under rolling particle contact and hot gas erosion.

Glass melting furnaces – Near feed and discharge ports for monitoring glass batch temperature (600–1200 °C) under particle impact and chemical attack.

Ceramic kilns – Conveyor exits for measuring ceramic body sintering temperature (500–1000 °C) amid dust and surface abrasion.

4. Mining & Chemical Industry

Solid particle handling in mining and chemical reactors leads to rapid sensor wear:

Mining crushing systems – Post-crusher and pre-screening ducts for monitoring ore temperature (ambient–200 °C) under stone impact.

Chemical fluidized bed reactors – FCC units, coal gasifiers for measuring catalyst or slag particle temperature (400–1000 °C) under fluidized abrasion.

Coal chemical plants – Pressurized coal gasifier inlets for monitoring coal–oxidant mix (300–800 °C) under high-pressure scouring.

5. Other Special Industrial Applications

Waste-to-energy plants – Furnace and flue gas ducts for measuring slag (600–1000 °C) and hot gas temperatures under corrosive dust wear.

Biomass power plants – Fuel feed ports and furnace interiors for measuring combustion temperature (500–900 °C) of biomass pellets and wood chips.

Summary:

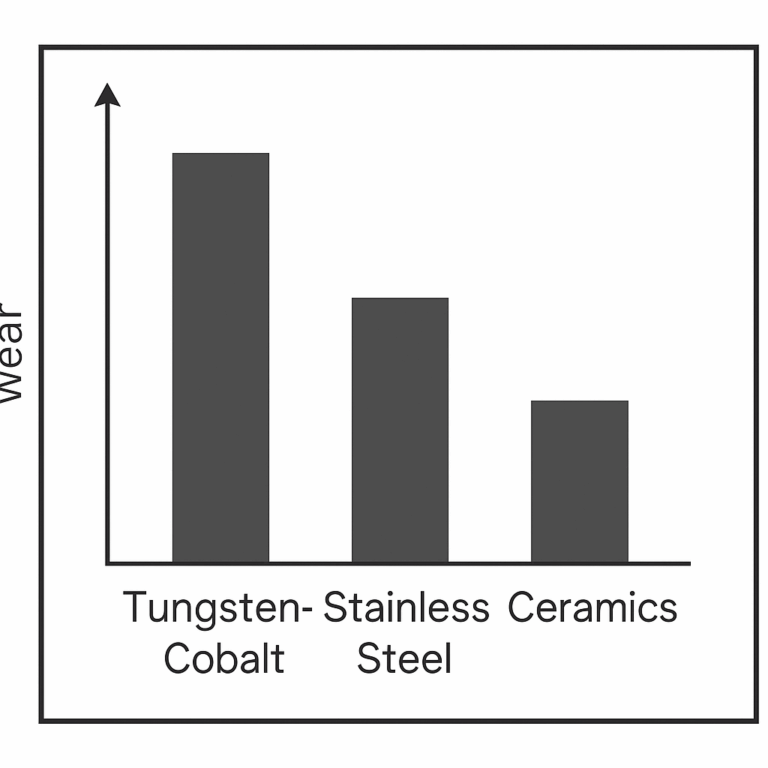

In any “High Temperature + High Abrasion” scenario, tungsten-cobalt alloy wear-resistant thermocouples outperform stainless steel or ceramic counterparts, reducing failure rates and ensuring process stability. They are essential in industries where hard particle flow and severe material impact occur, including power, metallurgy, building materials, mining, and chemical sectors.