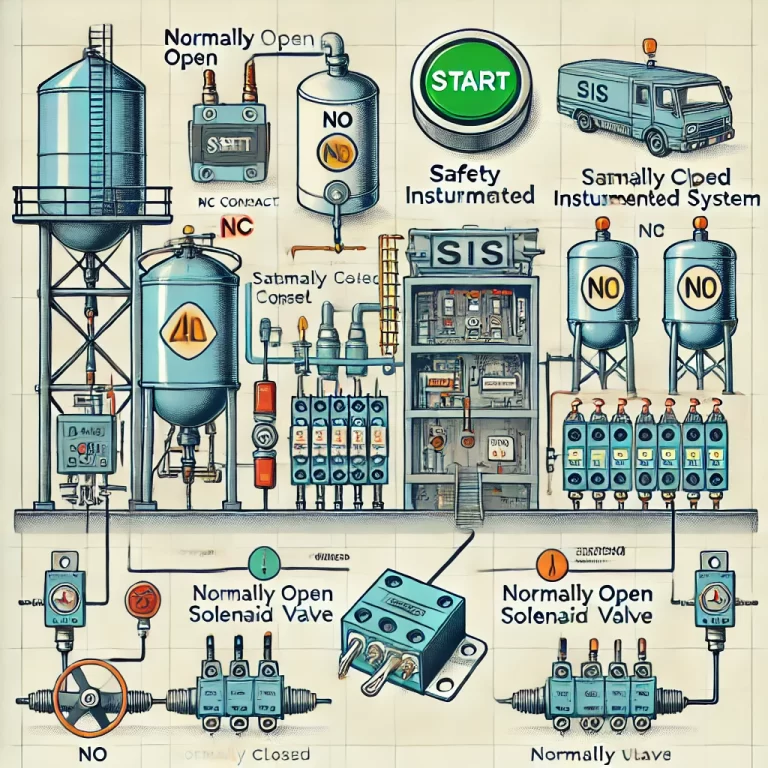

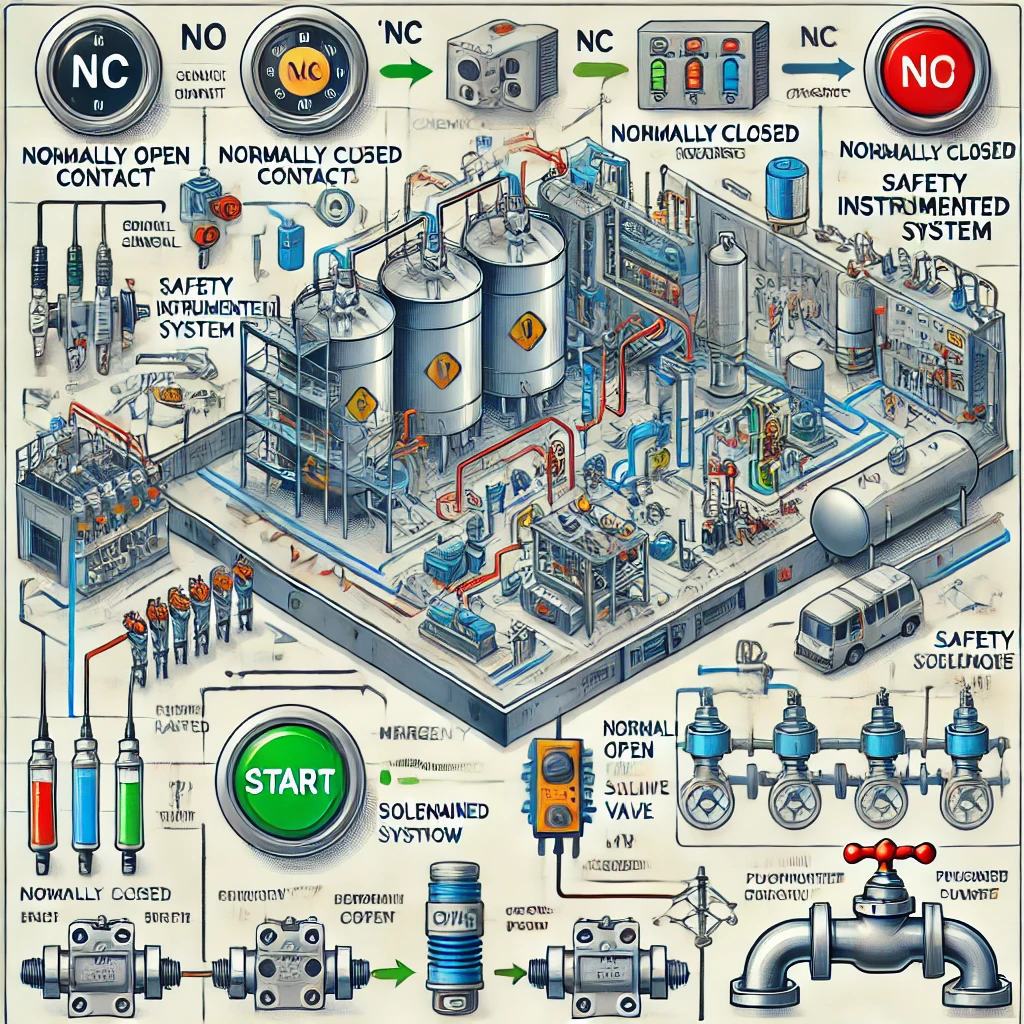

In Safety Instrumented Systems (SIS), the use of Normally Open (NO) and Normally Closed (NC) contacts and solenoid valves plays a vital role in ensuring operational safety and system reliability. This article provides an in-depth exploration of their operating principles, typical applications, failure modes, and how they align with safety principles and international standards.

1. NO and NC Contacts in SIS

1.1 Normally Closed (NC) Contacts

Working Principle: NC contacts remain closed during normal operation. If a fault occurs—such as a broken wire, contact failure, or power outage—the circuit opens, triggering a safety interlock and transitioning the system to a safe state.

Typical Applications:

Shutdown Signal Output: In many SIS applications, NC contacts are used for shutdown signals. For instance, in a chemical plant, if the liquid level exceeds a safe threshold, the level switch opens its NC contact, triggering a shutdown to prevent overflow.

Status Monitoring: NC contacts are used to confirm normal operating status. When a monitored device (e.g., valve or motor) is operating normally, the contact stays closed. Upon a failure or stop condition, the contact opens to issue a fault signal.

Failure Consideration: Failures in NC contact circuits typically manifest as an open state, causing a false shutdown. This type of failure, while causing downtime, adheres to the fail-safe principle by preventing unsafe conditions.

1.2 Normally Open (NO) Contacts

Working Principle: NO contacts remain open under normal conditions. When a specific condition is met or a command is received, the contact closes, sending a signal.

Typical Applications:

Start Function: NO contacts can be used in start buttons. Pressing the button closes the contact, sending a start command.

Enable Function: Used to allow system operation when certain prerequisites are met.

Bypass Function: In maintenance scenarios, NO contacts can be used to temporarily bypass interlocks.

Failure Consideration: Failures may result in contacts that cannot close, preventing system actions. Such failures are considered dangerous and must be mitigated by design and rigorous testing.

2. Solenoid Valves: NO vs. NC

2.1 Normally Open Solenoid Valves

Working Principle: Remain open without power. When energized, the valve closes.

Suitable Scenarios: Used in systems where fluid needs to flow continuously, such as HVAC systems or heating circuits. Powering the valve stops flow only when necessary.

Design Notes: The solenoid coil pulls against a return spring to close the valve.

2.2 Normally Closed Solenoid Valves

Working Principle: Remain closed without power. When energized, the valve opens.

Suitable Scenarios: Ideal for safety-critical systems such as fire suppression or emergency shutdowns. Keeps the valve shut until action is required.

Design Notes: Power energizes the solenoid coil, lifting the plunger against a spring to open the valve.

Troubleshooting Common Issues:

Abnormal Supply Voltage: Check for correct voltage and stable power.

Component Damage: Inspect solenoid coil, piston, or seals.

Contaminants: Clean internal components to ensure proper sealing.

Incorrect Wiring: Verify electrical connections and polarity.

Power Supply Faults: Replace or stabilize the power source.

3. Why NC Valves Are Preferred in SIS

3.1 Fail-Safe Principle

SIS design follows the fail-safe principle—systems must revert to a safe state in the event of a failure. NC solenoid valves, which close when power is lost, are ideal for ensuring containment and isolation.

3.2 Compliance with Standards

IEC 61511-1: Recommends using devices certified under IEC 61508, with many certifications applying only to NC versions of solenoid valves.

AQ 3059-2023: Chinese standard for liquefied hydrocarbon tank farms enforces fail-safe principles, making NC valves a better fit.

GB/T 50770-2013 (SIL Validation): NC solenoid valves have predictable failure modes that simplify Safety Integrity Level (SIL) calculations. They help achieve SIL 2 or SIL 3 in critical safety loops.

Conclusion

In conclusion, the proper selection and application of NO and NC contacts and solenoid valves is critical for the safety and reliability of SIS. Normally Closed components are typically preferred for shutdown and interlock functions, as they adhere more closely to fail-safe principles and international standards. However, practical application must also consider specific process requirements and functional needs to ensure a well-balanced and secure system design.