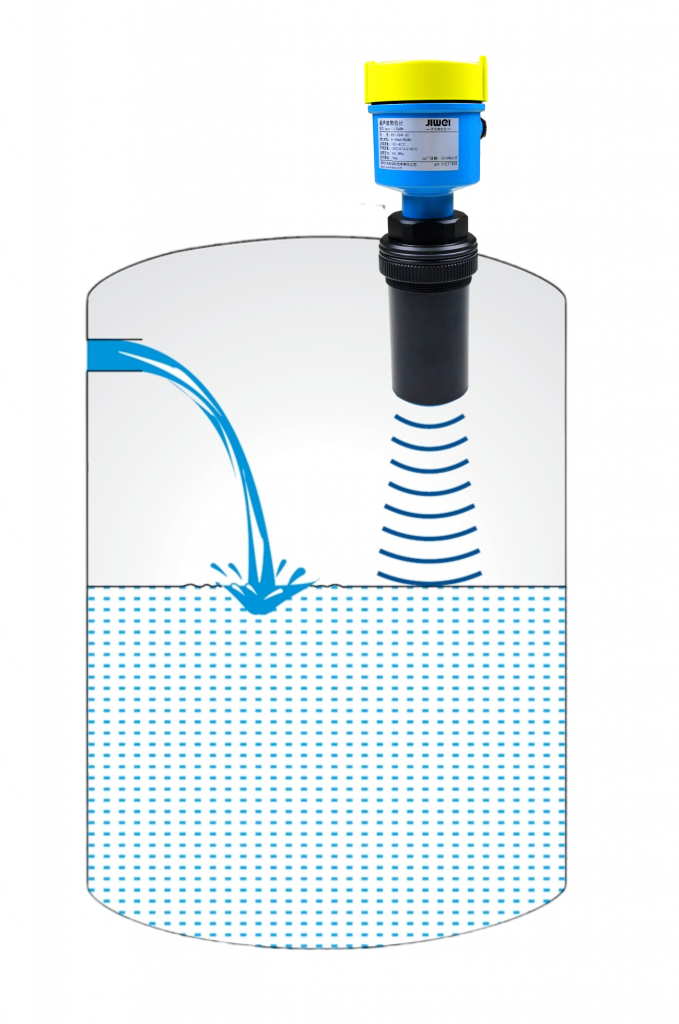

Ultrasonic level meters, with their non-contact measurement capability, high accuracy, and excellent adaptability, have become critical devices in water treatment and environmental protection projects. This article examines their detailed applications across various scenarios, supported by real-world examples and specific technical details.

1. Applications in Wastewater Treatment Systems

Wastewater Pool Level Monitoring

Ultrasonic level meters are widely used in critical wastewater treatment areas, such as aeration tanks, sedimentation tanks, and sludge thickening tanks, due to their non-contact measurement method. Using high-frequency pulse sound waves (20-200kHz), these meters can maintain a measurement accuracy of ±3mm, even in dynamic environments affected by vapor, foam, or agitation. For instance, Siemens’ SITRANS LU series meters have been implemented successfully in aeration tanks, optimizing aeration equipment operation and significantly enhancing microbial decomposition efficiency of organic pollutants.

Precise Chemical Dosing Control

Ultrasonic level meters effectively monitor chemical storage tanks, linking directly with dosing pumps to ensure accurate chemical addition. Their corrosion-resistant features, such as probes made from polytetrafluoroethylene (PTFE), effectively resist strong acidic and alkaline environments, significantly reducing maintenance compared to traditional float switches affected by cable aging. One wastewater plant adopted split-type ultrasonic level meters, eliminating issues related to sensor blockage caused by crystallized chemicals and extending maintenance intervals to over two years.

2. Applications in Urban Water Supply and Reservoir Management

Real-Time Reservoir Level Monitoring

With IP68 protection ratings, ultrasonic level meters withstand harsh environmental conditions, such as heavy rainfall and sediment, and offer a wide measurement range (0-60m) with millimeter-level accuracy. Such precise measurements aid flood control decision-making by accurately regulating gate operations and reservoir storage capacity. A prominent hydraulic hub project employed ultrasonic level meters with temperature compensation, maintaining level measurement errors below ±0.1%, significantly improving water resource management efficiency during dry periods.

Water Supply Network and Storage Tank Safety

Ultrasonic level meters, featuring external mounting capabilities, allow non-intrusive monitoring of sealed water tanks without damaging pipes. With their 4-20mA outputs directly integrated into SCADA systems, they trigger alarms upon exceeding safety thresholds, preventing pipe bursts or overflows. A city water supply initiative resolved measurement errors caused by multi-path reflections within confined spaces by employing narrow-beam (8°) ultrasonic level meters.

3. Applications in Drainage and Flood Control Systems

Intelligent Control of Pump Stations

Ultrasonic level meters continuously monitor sump levels, interfacing with PLC systems to automate pump operations, preventing equipment dry running or wastewater overflow. One municipal pumping station utilized three-wire ultrasonic level meters powered by 24V DC, achieving remarkable performance in environments with strong electromagnetic interference, resulting in a 70% reduction in annual failure rates.

Urban Underground Network Monitoring

Designed with IP66-rated moisture and dust-resistant housings, ultrasonic level meters efficiently operate in complex environments like manholes and box culverts. Their adaptive sound speed calibration technology compensates for temperature variations, ensuring accurate readings. A smart city project installed these meters in 1.5-meter-diameter drainage pipes, successfully enabling real-time flood level warnings during heavy rainfall events.

4. Key Advantages and Technological Innovations

Core Technical Advantages:

Non-contact Measurement: Suitable for corrosive or viscous liquids, avoiding contamination.

Robust Environmental Adaptability: Operational in temperatures from -40°C to 80°C, resistant to interference from vapor and foam.

Advanced Intelligence: Enhanced with AI-driven echo analysis and IoT-based remote monitoring capabilities.

Future Technological Trends: The next-generation ultrasonic level meters will integrate additional sensors, such as pressure sensors and probe arrays, offering multi-dimensional data including liquid levels, flow rates, and medium density. For example, a pilot environmental project using 3D acoustic imaging technology improved sediment thickness monitoring in sedimentation tanks, boosting sludge removal efficiency by 40%.

5. Conclusion and Outlook

Due to their precision, adaptability, and low maintenance requirements, ultrasonic level meters have become indispensable in water treatment and environmental management. As smart water management systems evolve, ultrasonic level meters will increasingly be applied to advanced analytical domains like water quality control and energy optimization, significantly contributing to more efficient, sustainable management practices.