Introduction

Liquid nitrogen (LN2) is widely used across industries, medical fields, and research laboratories as a cryogenic liquid, stored at extremely low temperatures of around -196°C. Maintaining the stability of liquid nitrogen distribution systems is critical to ensuring their efficiency during vaporization and distribution processes. Tuning fork level switches, known for their high reliability and anti-interference capabilities, are extensively used in monitoring liquid levels in such systems. By providing real-time liquid level detection, these switches ensure the safe and efficient operation of equipment like vaporizers and distribution pipelines.

This article explores the application of tuning fork level switches in a liquid nitrogen distribution system, detailing their working principles, challenges they address, and the advantages they offer.

Project Background

A medical gas supply company (hereafter referred to as “the company”) is responsible for delivering liquid nitrogen gas and related services to various hospitals and research institutions. Liquid nitrogen is primarily used for cryopreservation, cooling laboratory equipment, and other high-precision applications.

The company operates a liquid nitrogen storage and distribution system consisting of three main components:

- Liquid Nitrogen Storage Tanks: Store LN2 at cryogenic temperatures.

- Liquid Nitrogen Vaporizers: Convert liquid nitrogen into gaseous nitrogen for end-user applications.

- Distribution Pipelines: Transport the gas to various endpoints.

Accurate liquid level monitoring is critical to the system. For instance:

- Low liquid levels in vaporizers or pipelines can lead to dry operation, causing equipment damage or gas supply disruptions.

- High liquid levels can result in overflows, increased pressure, and potential damage to the system.

To address these issues, the company integrated tuning fork level switches to enhance real-time monitoring of liquid nitrogen levels, ensuring system stability and reliable gas supply.

Working Principle of Tuning Fork Level Switches

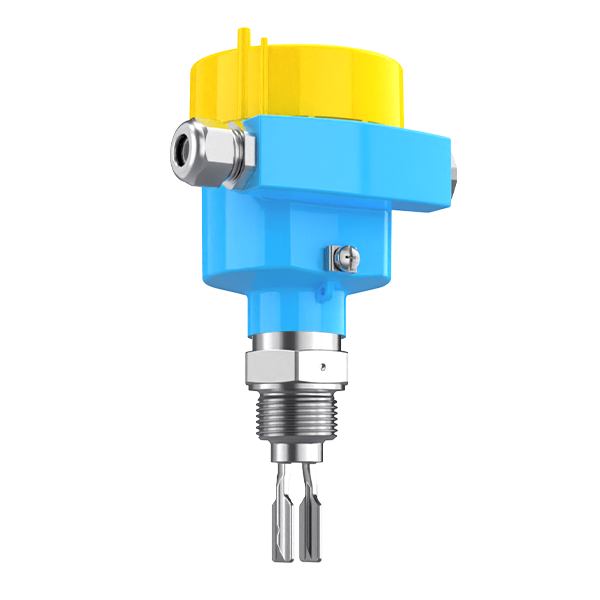

Tuning fork level switches operate on the principle of vibrational frequency change. When the fork-shaped probe of the switch is immersed in a liquid, the liquid dampens its vibrations, altering the frequency. This frequency change is detected by the electronic circuitry within the switch, triggering an alert or action based on pre-defined thresholds.

Key features of tuning fork level switches include:

- Reliability in Extreme Environments: They are effective in low-temperature conditions and environments with fluctuating pressures.

- Anti-Interference Capability: These switches can handle bubbles, vapor, and other disturbances without compromising accuracy.

- Compact Design and Easy Maintenance: Their simple construction ensures easy installation and minimal maintenance.

Challenges in Liquid Nitrogen Distribution Systems

Liquid nitrogen distribution systems face several operational challenges:

- Temperature Extremes: Components in the system operate in a range of -80°C to -150°C. Monitoring devices must remain stable under these conditions.

- Pressure Fluctuations: Rapid changes in pressure during nitrogen vaporization can affect the accuracy of monitoring.

- Interference from Bubbles and Vapors: During liquid nitrogen flow, bubbles and vapors can disrupt level detection systems.

- Criticality of Accurate Monitoring: A single failure in level monitoring can lead to cascading issues, including equipment damage, process interruptions, or safety hazards.

Tuning fork level switches are particularly suited to these environments due to their robust design and resistance to environmental disturbances.

Applications in Liquid Nitrogen Distribution Systems

Tuning fork level switches were installed at three critical points within the company’s liquid nitrogen system:

1. Liquid Nitrogen Vaporizer Level Monitoring

- Purpose: Vaporizers convert liquid nitrogen to gaseous nitrogen for end-user applications. Maintaining the correct liquid level ensures efficient vaporization.

- Application: The switches were installed at the liquid nitrogen inlet of the vaporizers. They monitor the input levels in real-time, preventing issues like dry operation, which could damage the vaporizer and disrupt supply.

- Result: Real-time feedback allows operators to adjust the vaporizer’s operating parameters, ensuring continuous nitrogen supply and reducing safety risks.

2. Pipeline Distribution Level Monitoring

- Purpose: Pipelines distribute vaporized nitrogen to various endpoints. Liquid levels in the pipelines must be carefully managed to avoid pressure abnormalities or supply interruptions.

- Application: The switches were installed at critical nodes in the distribution network to ensure stable levels. They detect potential overflows or deficiencies and trigger corrective actions.

- Result: The system’s stability improved significantly, as the switches mitigated issues caused by external environmental changes or pipeline configurations.

3. Intermediate Storage Tank Level Monitoring

- Purpose: While tuning fork level switches are unsuitable for ultra-low-temperature storage tanks (-196°C), they are effective in intermediate tanks operating at -80°C to -100°C.

- Application: The switches were used to monitor liquid levels in intermediate storage tanks, providing an additional layer of reliability in the supply chain.

- Result: This ensured a steady supply of nitrogen to downstream equipment, reducing the risk of supply chain disruptions.

Project Outcomes and Advantages

Integrating tuning fork level switches into the liquid nitrogen distribution system yielded several benefits:

Enhanced System Stability:

- Reliable liquid level monitoring reduced the likelihood of equipment malfunctions and supply interruptions.

Strong Anti-Interference Performance:

- The switches effectively handled disturbances like bubbles and vapors, ensuring accurate detection in challenging environments.

Reduced Maintenance Costs:

- Their robust design required minimal maintenance, reducing downtime and overall operational costs.

Improved Safety:

- By preventing issues like dry operation and liquid overflows, the switches significantly reduced operational risks.

Conclusion

The deployment of tuning fork level switches in the liquid nitrogen distribution system highlighted their advantages in reliability, anti-interference capability, and adaptability to extreme conditions. By providing real-time monitoring, these switches enhanced the safety and efficiency of liquid nitrogen operations.

Future improvements may include integrating advanced sensors with higher temperature tolerances to expand their application range and incorporating digital monitoring systems for even greater precision and automation.