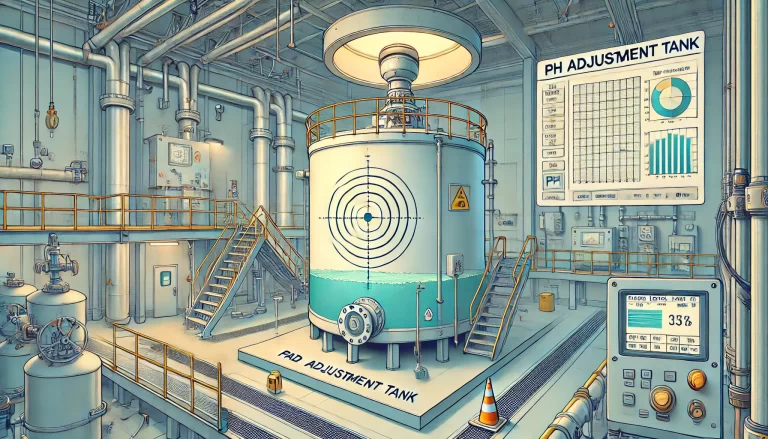

pH adjustment tanks play a vital role in numerous chemical and biological processes, where the accurate measurement of liquid levels is crucial for effective pH control. This article discusses how advanced radar level transmitters are used for level measurement in pH adjustment tanks, ensuring precise and reliable process control.

Importance of pH Control in Industrial Processes

In various industrial and academic settings, pH control is fundamental to ensuring the proper progression of chemical reactions, biological fermentation, and diverse production processes. Industries such as biopharmaceuticals, food processing, and chemical manufacturing rely heavily on maintaining specific pH levels. The pH value directly affects product quality and yield, as well as the stability and safety of the production process. Therefore, real-time monitoring and precise control of pH levels are essential.

Radar Level Transmitter: Working Principle and Advantages

A radar level transmitter is a high-precision level measurement instrument that operates using electromagnetic waves. It emits microwave signals toward the liquid surface and measures the time taken for the reflected signal to return. This measurement provides the liquid level in the tank. Radar level transmitters offer several advantages:

Non-contact measurement: The transmitter does not come into contact with the liquid, making it suitable for harsh and corrosive environments.

High accuracy: The precision of radar technology ensures reliable measurements.

Corrosion resistance: Suitable for corrosive media found in pH adjustment tanks.

Adaptability: Performs well under extreme conditions, such as high temperature and pressure.

These features make radar level transmitters widely applicable in complex industrial scenarios.

Challenges of Traditional Level Measurement Methods

Traditional methods, such as float-type and capacitive level sensors, often face challenges in environments with corrosive media or extreme conditions. These methods are prone to inaccuracies due to their contact with the medium, which can lead to equipment wear, reduced lifespan, and compromised reliability. Radar level transmitters effectively overcome these limitations.

Practical Application in a Chemical Plant

In a large chemical plant’s pH adjustment system, a 26GHz high-frequency radar level transmitter was installed at the top center of a pH adjustment tank using a flange-mounted configuration. This setup ensures stability and accuracy under various operating conditions. The installation process included the following steps:

Determining the installation location: The position was selected to ensure that the radar beam could cover the entire tank without interference from internal structures.

Calibrating the empty tank: The zero point was set at the lowest level alarm point (E).

Calibrating the full tank: The current maximum liquid level (F) was input, completing the basic configuration.

Parameter adjustments: Parameters were fine-tuned based on the specific medium to maintain measurement accuracy across different conditions.

Continuous Monitoring and Control

The radar level transmitter continuously collects data on the liquid level within the pH adjustment tank and transmits this data to the central control system. Using a dedicated software platform, operators can monitor real-time level changes and adjust the amount of acid or alkali added to maintain the desired pH range. The system’s data logging capabilities allow for historical data review, aiding in future process optimization and analysis.

Maintenance and Operational Benefits

Maintenance of radar level transmitters is relatively straightforward. Regular checks involve ensuring secure connections, inspecting for signs of corrosion, and occasionally cleaning the antenna to remove any buildup. Due to the non-contact nature of radar technology, routine maintenance requirements are minimal, significantly reducing workload and associated costs.

Conclusion

As an advanced level measurement instrument, the radar level transmitter enhances the accuracy and reliability of liquid level monitoring in pH adjustment tanks. This innovation not only improves production management but also simplifies maintenance efforts, offering substantial benefits to industrial operations.