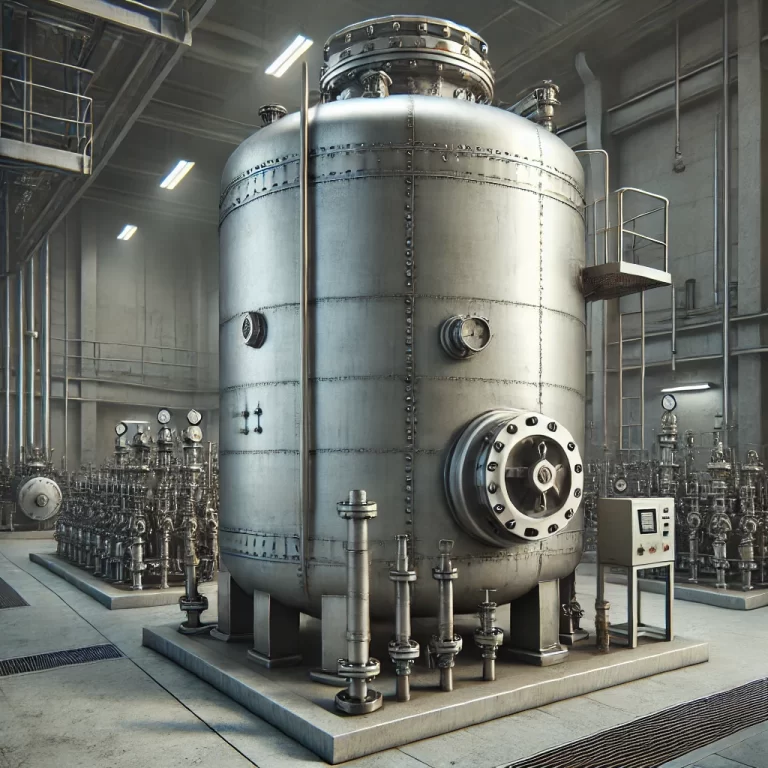

In modern industrial production, precise level measurement is not only crucial for enhancing production efficiency but also serves as the foundation for process safety and stability. With technological advancements, radar level transmitters, known for their unique non-contact measurement capabilities, have demonstrated exceptional value in complex industrial environments such as diazo reaction kettles.

A diazo reaction kettle is a common piece of equipment in chemical production used for diazotization reactions. These reactions are often accompanied by intense chemical reactions, temperature changes, and pressure fluctuations, posing stringent requirements for level measurement. Traditional level measurement methods, such as manual dipsticks and float-type level meters, have low accuracy and reliability and cannot monitor level changes in real time, which fails to meet the needs of modern chemical production.

A radar level transmitter is an instrument based on the principle of electromagnetic wave reflection. It emits electromagnetic waves towards the liquid surface through an antenna and receives the signals reflected back from the liquid surface. By calculating the time delay or frequency change of the electromagnetic wave’s travel, the liquid level height is determined. This non-contact measurement method allows radar level transmitters to adapt to various complex environments and media, especially those involving high temperatures, high pressures, or highly corrosive liquids, making them particularly advantageous.

Compared to traditional level measurement methods, radar level transmitters offer significant advantages when applied to diazo reaction kettles:

- High Measurement Accuracy: The advanced electromagnetic wave reflection principle ensures high precision, accurately reflecting liquid level changes.

- Real-Time Monitoring: Radar level transmitters can continuously monitor liquid level changes and transmit data to control systems, enabling operators to adjust process parameters promptly.

- Adaptability to Complex Environments: Radar level transmitters perform exceptionally well in high-temperature, high-pressure, and highly corrosive environments.

- Stability and Reliability: They are not affected by temperature, pressure, foam, dust, and other factors, ensuring stable and reliable measurements.

For instance, in a chemical plant utilizing a diazo reaction kettle, the implementation of radar level transmitters as the primary measurement instrument yielded significant benefits:

- Real-time monitoring allowed operators to adjust feed rates and reaction conditions, thereby enhancing production efficiency.

- Accurate and reliable measurements helped identify abnormal liquid levels promptly, preventing safety incidents caused by excessively high or low levels.

- The non-contact measurement approach reduced direct interaction with the media, minimizing wear and corrosion on the instruments and thus reducing maintenance costs.

The application of radar level transmitters in diazo reaction kettles not only improved production efficiency and safety but also lowered maintenance expenses.