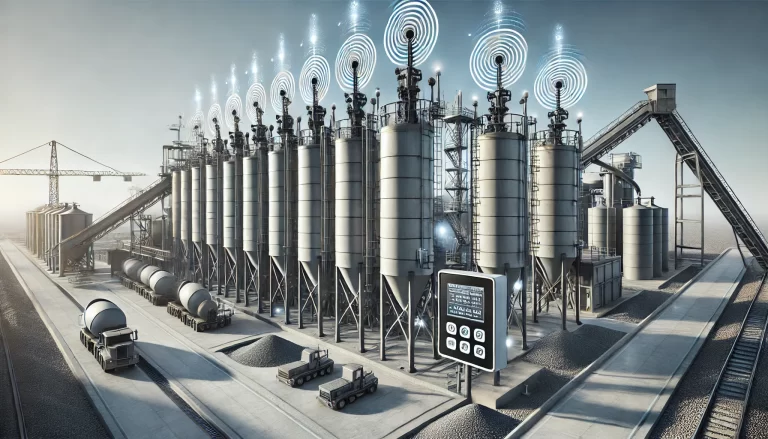

In recent years, with the continuous advancement of infrastructure construction in China, asphalt concrete has become a crucial material in road construction. During the production of asphalt concrete, monitoring and measuring the material levels in silos is key to ensuring smooth production. However, traditional methods of level measurement often have limitations, such as low accuracy and susceptibility to environmental factors. To overcome these challenges, radar level meters have emerged as a solution and are now widely applied in measuring material levels in asphalt concrete silos.

Asphalt concrete is a composite material made from a mixture of asphalt, aggregate, and filler in specific proportions, widely used in roads, bridges, and airport runways. Its excellent performance has made it the material of choice for modern transportation infrastructure. In the production process, the material level in silos directly impacts production continuity and stability. Accurate level measurement helps ensure smooth operations, avoiding production interruptions or waste due to material shortages or overflows. Additionally, level data is critical for businesses in managing materials, optimizing inventory, and controlling costs.

Traditional methods for level measurement mainly include manual measurements and mechanical methods. These approaches have drawbacks, such as low precision, environmental interference, and cumbersome operations, making them insufficient for modern asphalt concrete production.

Radar Level Meter: Working Principle and Installation

A radar level meter is a measurement instrument based on radar wave distance measurement. It works by emitting high-frequency radar pulses through a probe. When these radar waves hit the surface of the material, they are reflected and received by the instrument’s receiver. The distance from the probe to the material surface is calculated based on the time difference between emission and reception, combined with the speed of light, to determine the material level.

In asphalt concrete silos, radar level meters are usually installed at the top or on the sidewalls of the silo. The installation site should avoid areas that may cause interference, such as feed inlets and mixers, to ensure accurate and stable measurements. There are multiple installation methods for radar level meters, including flange mounting, threaded mounting, and bracket mounting. The specific installation method should be chosen based on the silo’s actual conditions and the user’s needs. For example, in circular silos, flange mounting may be used, while in square or rectangular silos, threaded or bracket mounting might be more suitable.

After installation, the radar level meter needs parameter configuration and debugging. The settings include measurement range, output signal type, and alarm points. During the debugging process, it is essential to ensure the radar level meter accurately measures the material level and outputs stable signals. Additionally, adjustments to the probe’s installation angle and position may be needed to eliminate potential interference.

Advantages and Future Applications

In practical use, radar level meters have demonstrated excellent performance and stability in asphalt concrete silos. They can monitor real-time changes in material levels and transmit data to control systems or host computers for display and record-keeping. When the material level reaches preset upper or lower limits, the radar level meter can automatically trigger an alarm system, alerting operators to take timely action. Furthermore, radar level meters are equipped with remote monitoring features, allowing users to check material levels and device status anytime, anywhere, via mobile apps or web browsers.

As technology continues to advance and asphalt concrete production methods evolve, the application of radar level meters in silo measurement shows great promise for the future. Their ability to provide accurate, real-time measurements, combined with ease of integration into control systems and remote monitoring capabilities, makes them an increasingly vital tool in ensuring efficient and reliable asphalt concrete production.