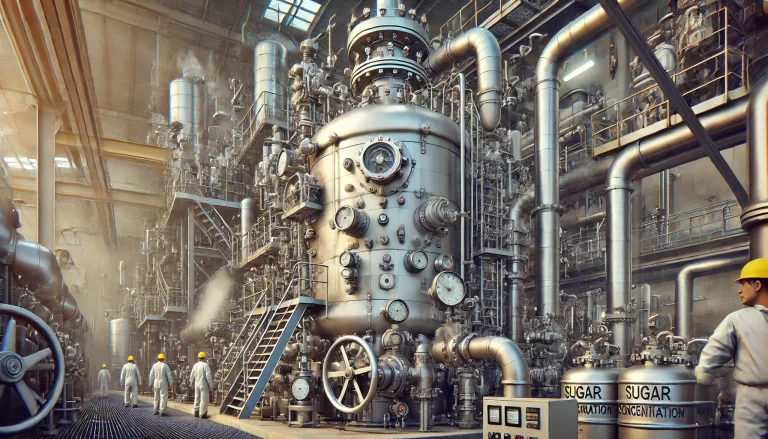

In the food processing industry, especially in the production of sucrose, the sugar concentration evaporator plays a vital role. Its main function is to remove water through the evaporation process, increase the concentration of sugar solution, and prepare for the subsequent crystallization and separation process.

In this process, accurate measurement of the liquid level inside the evaporator is essential to ensure evaporation efficiency, product quality and process safety. This is exactly the scenario where radar level gauges come into play. As an advanced level measurement device, it can provide high-precision and high-reliability measurement data.

Level measurement in sugar concentration evaporators faces multiple challenges. First, the dielectric constant of sugar solution changes with increasing concentration, which is a special consideration for level measurement equipment using radar technology. Second, the temperature during sugar concentration and evaporation is extremely high, often reaching over 100 degrees Celsius, which places higher requirements on the high temperature resistance of the measurement equipment.

In addition, there is often a large amount of steam and condensed water in the evaporator, which will interfere with the accuracy of level measurement and the stability of the equipment. In the face of these challenges, radar level meters can effectively cope with them due to their non-contact measurement characteristics.

Its core advantage is that it measures the distance by emitting microwave signals and receiving the reflected signals, without direct contact with the medium, thereby reducing the impact of temperature and pressure on the measurement results. In addition, high-frequency radar level meters can provide shorter wavelengths, allowing them to maintain excellent measurement performance in high steam environments.

In the process of selecting a radar level meter, it is necessary to determine the most suitable model and configuration according to the specific working conditions of the evaporator. For example, choose equipment with high temperature resistance and use a frequency suitable for measuring high dielectric constant media.

When installing, ensure that the location of the radar level meter can avoid direct interference from steam and is easy to maintain and calibrate. At the same time, considering possible contamination and scaling problems, it is a wise choice to choose an antenna design with automatic cleaning or easy cleaning.

Although the application of radar level meters in sugar concentration evaporators has brought significant improvements, some problems may still be encountered in actual operation, such as signal attenuation, interference, etc. For these problems, regular maintenance and calibration are the key to ensure measurement accuracy.

At the same time, the use of advanced data processing algorithms and software can further optimize the measurement results and improve the robustness and reliability of the entire system.

In the sugar concentration evaporator, accurate measurement of the liquid level is crucial to the efficient operation of the entire production process. Radar level meter, with its high precision, high stability and strong adaptability, has become an ideal choice to solve this problem.

Through reasonable selection and correct installation, as well as effective maintenance and data processing, radar level meter can ensure that the liquid level measurement in the sugar concentration evaporator is both accurate and reliable, thus providing solid technical support for the smooth progress of sugar production.