1. Background

Urban water supply systems rely heavily on modern communication, control, and sensing technologies to ensure safe, efficient, and reliable water distribution. Among these technologies, pressure sensors play a crucial role in monitoring pipeline conditions, detecting system faults early, optimizing maintenance efforts, and minimizing operational risks.

By continuously measuring pipeline pressure and transmitting real-time data to control centers, pressure sensors support predictive maintenance, emergency response, and water loss reduction—contributing to the overall goals of cost reduction, service continuity, and improved efficiency in smart water networks.

2. Typical Installation Locations and Functions

Pressure sensors are typically installed at strategic locations along the municipal water network, such as:

Main trunk pipelines

Valve chambers and pump outlet lines

Pressure-reducing valve zones

High- and low-altitude transition areas

These sensors are configured with upper and lower alarm thresholds. When the pressure value exceeds the normal range—either too high or too low—it triggers alerts for maintenance personnel to respond quickly, thus preventing pipeline bursts, backflow, or water supply interruptions.

3. Key Technical Specifications

| Parameter | Description |

|---|---|

| Material | Stainless steel housing (typically 304 or 316L), compatible with potable water |

| Pressure Range | -100 kPa (vacuum) to 0–100 MPa (gauge or absolute), customizable per application |

| Output Signal | – Analog: 4–20 mA, 0–10 V – Digital: RS485 Modbus RTU, HART – Optional wireless (NB-IoT, Lora) |

| Power Supply | 24V DC (standard), optional battery-powered for remote locations |

| Accuracy Class | 0.1% FS, 0.25% FS, 0.5% FS, 1.0% FS—selectable based on required precision and budget |

| Ingress Protection (IP) | IP65, IP67 or higher for outdoor/wet environments |

| Response Time | <10 ms (typical) |

⚠ Note: High-accuracy sensors (≤0.25% FS) are recommended for pressure-sensitive zones and SCADA-integrated networks.

4. Advantages of Using Pressure Sensors in Water Supply Networks

High Accuracy and Stability: Ensures reliable long-term monitoring of pipeline pressure.

Fast Response Time: Capable of detecting sudden pressure surges or drops.

Robust Construction: Withstands humidity, corrosion, and mechanical stress in underground or outdoor installations.

Versatile Integration: Compatible with PLC, DCS, SCADA, and IoT platforms for remote management.

5. Installation and Maintenance Recommendations

To ensure long-term performance and ease of maintenance:

Install a shut-off valve between the pressure tapping point and the sensor to allow for sensor removal without system shutdown.

Ensure a stable flow region at the tapping location—avoid turbulent zones such as elbows, tees, or pump outlets.

Calibrate periodically based on manufacturer guidelines and local water authority standards.

Use protective enclosures for outdoor installations to shield against direct sunlight, rain, and tampering.

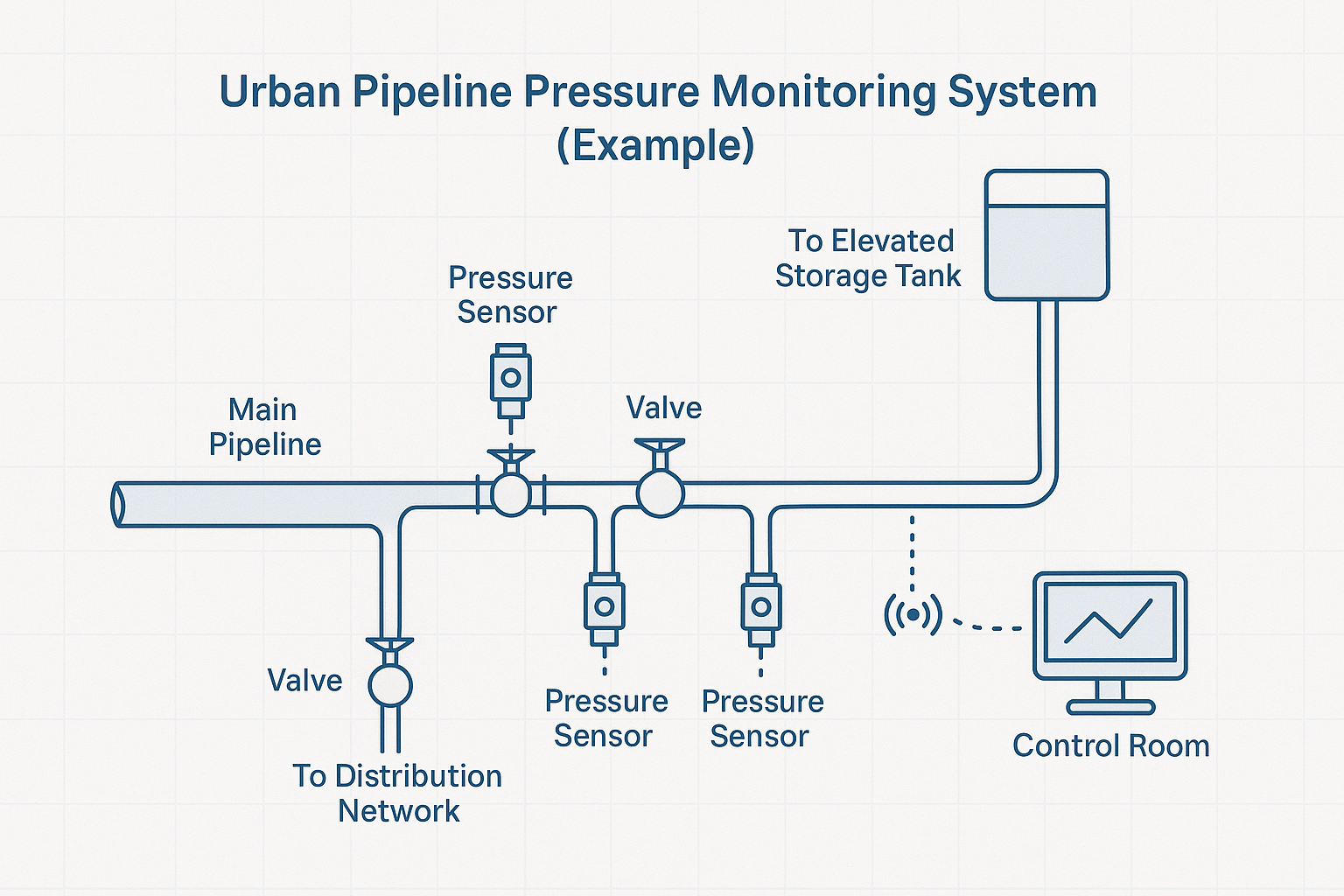

6. Diagram: Urban Pipeline Pressure Monitoring System (Example)