1. Introduction to Closed-Loop Control

A typical closed-loop automatic control system follows this sequence:

Error → Controller Calculation → Output → Actuator Adjustment → Feedback

Key components:

Setpoint (SP): Desired target value (e.g., temperature, flow rate).

Process Variable (PV): Real-time value measured by the sensor.

Error (e): The difference between SP and PV (e = SP − PV).

Controller: Computes the control signal based on the error.

Actuator: Adjusts the system based on the controller’s output.

Process (Plant): The physical system being controlled.

2. What is PID Control?

PID (Proportional–Integral–Derivative) control is a fundamental feedback algorithm widely used in industrial automation to minimize error and maintain system stability.

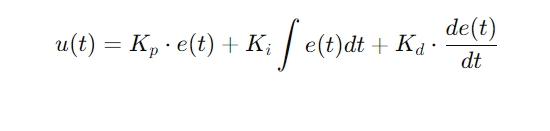

Standard PID Formula:

Where:

u(t): Output signal to the actuator

e(t): Error signal (SP − PV)

Kp,Ki,Kd: Proportional, Integral, and Derivative gains

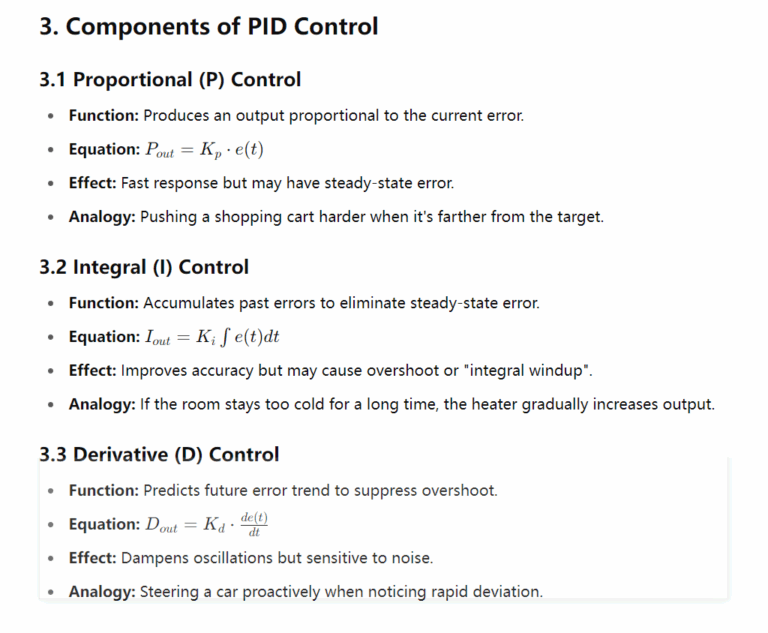

4. PID Modes and Tuning

4.1 Common Control Modes

| Mode | Description | Typical Use |

|---|---|---|

| P | Simple, fast, but may leave offset | Position control |

| PI | Eliminates steady-state error | Temperature, level |

| PD | Good dynamic response | Speed, robotics |

| PID | Balanced performance | General purpose |

4.2 Tuning Methods

Manual Tuning: Trial and error.

Ziegler-Nichols Method: Based on ultimate gain and oscillation period.

Model-Based Tuning: Uses a mathematical model of the system.

Auto-Tuning: Available in modern controllers.

⚠ Note: Improper tuning may cause oscillations (over-tuned) or sluggish response (under-tuned). Anti-windup and filtering techniques are essential for practical stability.

5. Application Scenarios

5.1 Temperature Control

Uses PID to regulate heating/cooling power.

Example: Electric furnace, HVAC system.

5.2 Motor Speed/Position Control

Adjusts current or PWM to maintain set speed/position.

Example: Fans, CNC, robotics.

5.3 Autonomous Driving

PID used for steering and throttle control in AVs.

Ensures smooth path tracking and stability.

5.4 Other Applications

Liquid level control

Pressure regulation

Auto-focusing systems

High-precision robotics

6. PID Control in DCS and SIS

6.1 In DCS (Distributed Control System)

Widely used in chemical, power, and pharmaceutical industries.

Every process variable (e.g., temperature, pressure, flow) typically has a dedicated PID loop.

Features: Online tuning, trend history, alarm integration.

Advantages:

Supports complex process control

Facilitates centralized management

6.2 In SIS (Safety Instrumented System)

SIS is designed for plant and personnel protection.

Normally uses simple logic (ON/OFF or hardwired interlocks).

In special safety control cases (e.g., pressure relief buffering), PID may be adopted.

Key Differences:

| Aspect | DCS | SIS |

|---|---|---|

| Main Goal | Process control & efficiency | Safety protection |

| PID Usage | Common & extensive | Rare, only for special cases |

| Logic Type | Continuous control loops | Discrete logic, simple PID |

6.3 Collaboration Between DCS and SIS

Shared data, alarm interlock integration.

DCS PID ensures efficiency, SIS safeguards the system.

7. Conclusion

PID remains the cornerstone of modern industrial control systems due to its:

Simplicity

Robustness

Tunability

Broad compatibility

Despite the emergence of advanced control techniques (adaptive, fuzzy logic), PID continues to dominate in real-world deployments, particularly within DCS environments. Its role in SIS is more limited but still relevant for specific safety-critical adjustments.