Introduction

Magnetic level indicators (MLIs) have become a reliable and essential solution for continuous level monitoring in extreme industrial environments. Known for their durability, modular design, and passive measurement principles, MLIs are widely adopted in high-temperature, high-pressure, corrosive, and hazardous scenarios. This article explores the advanced applications of MLIs, offering insight into material adaptation, structural enhancements, functional upgrades, real-world case studies, and strategies to overcome technical challenges.

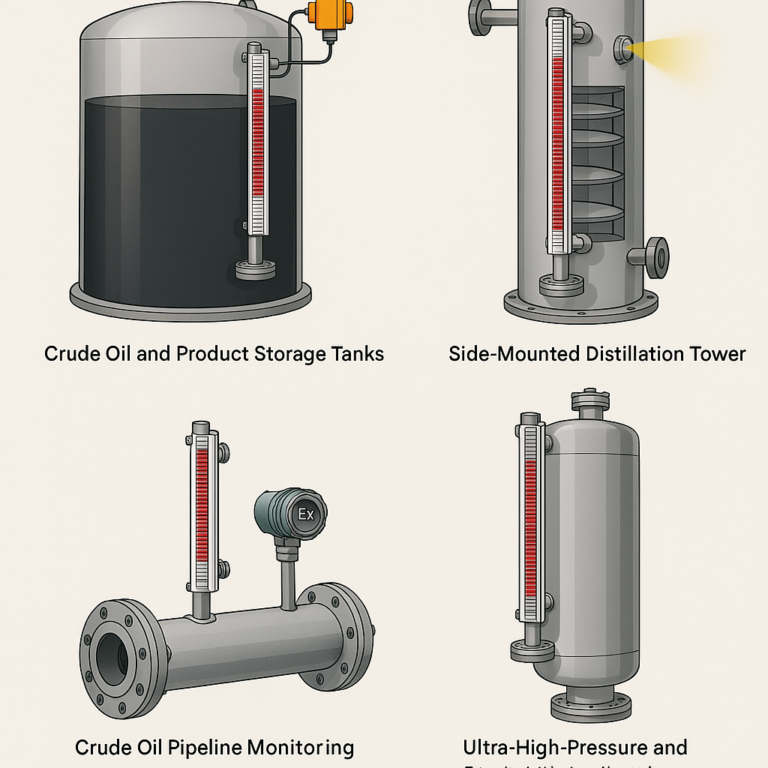

1. Typical Harsh Environments for MLI Deployment

🔹 High-Temperature and High-Pressure Applications

In hydrocracking reactors (≤350°C / 15MPa) within petrochemical plants, MLIs often utilize Hastelloy C276 floats and vacuum-jacketed chambers, coupled with high-pressure flanged connections (e.g., DN50 / Class 1500). These configurations ensure resistance to rapid phase transitions and thermal shocks. For instance, an MLI with a steam jacket operated continuously for over 12 months at 420°C in a cracking unit without failure.

🔹 Highly Corrosive Media

Acid Pickling Tanks: For environments involving 98% sulfuric acid or 37% hydrochloric acid, PTFE-lined chambers (≥3mm thickness) and tantalum floats are used, achieving C4 corrosion resistance and extending service life to over 8 years.

Chlor-Alkali Electrolyzers: Operating in brine solutions with Cl⁻ concentrations of 200,000 ppm, MLIs equipped with Grade 2 titanium chambers and fluororubber seals ensure accurate readings across pH 0–14.

🔹 Flammable and Explosive Zones

In oil and gas storage tanks (certified Ex d IIC T4), MLIs integrate intrinsically safe magnetic switches (Ex ia IIB T6), enabling emergency interlock activation within 30ms and effective signal transmission over 15 meters, compliant with API 2350.

🔹 High Viscosity and Solid-Containing Fluids

Asphalt Storage: For fluids with viscosity >10⁴ mPa·s, MLIs are designed with wide-bore DN80 chambers and hollow titanium floats (0.6g/cm³). High-pressure steam flushing ports (0.8MPa) are added to prevent float blockage.

Slurry Reactors: In media containing up to 40% solid content, MLIs incorporate self-cleaning scraper mechanisms and N52-grade magnets, maintaining accuracy within ±3%.

🔹 Cryogenic Conditions

In LNG tanks (-162°C), specially designed MLIs use vacuum-jacketed insulation, cryogenic magnetic flaps (resistant to -196°C), and Modbus RTU communication for real-time data integration into SCADA systems, with level resolution reaching 1mm.

2. Technical Adaptation Strategies for Harsh Environments

🧪 Material Enhancements

Corrosion Resistance: Specialized alloys such as Hastelloy, Monel, and titanium, combined with PTFE or PP linings, provide full pH 0–14 coverage and resist Cl⁻ concentrations up to 25%.

High-Temperature Components: Use of samarium-cobalt magnets (rated for 350°C) and ceramic bearings ensures magnetic coupling stability.

🏗 Structural Reinforcements

Explosion-Proof Design: Full-welded sealing and flameproof housings certified to IEC 60079 standards.

Anti-Vibration Measures: Damping devices and dual-guide rod configurations withstand vibrations of 5–200Hz with amplitudes ≤2mm.

💡 Functional Expansions

Smart Diagnostics: HART-compatible transmitters (accuracy 0.1%FS) support temperature compensation, media density adjustment, and self-diagnostics.

Redundant Calibration: Integration with radar/ultrasonic modules corrects linear deviations up to ±1.5% under high pressure.

3. Real-World Application Cases

🏭 Delayed Coking Unit in Refinery

Under 460°C and 4MPa, Hastelloy MLIs with a range of 0–8 meters are linked to emergency quench control systems via 4–20mA signals. This setup prevented nine overflow incidents annually and extended maintenance cycles to 18 months.

⚗ Titanium Dioxide Acid Decomposition Line

MLIs with PTFE linings withstand 180°C and mixed media of 65% sulfuric acid and titanium ore slurry. Combined with high-pressure cleaning, service life improved from 6 months to 5 years.

🧊 LNG Terminal Storage Tanks

Cryogenic MLIs transfer data in real-time via RS485 and support AI algorithms to optimize loading/unloading schedules, increasing operational efficiency by 12% per batch.

4. Challenges and Engineering Solutions

| Challenge | Cause or Risk | Technical Solution |

|---|---|---|

| High-Temperature Coking | Carbon fouling on float surface >400°C | Apply Al₂O₃ ceramic coating (50μm) to reduce fouling by 70% |

| Cryogenic Seal Failure | Brittle failure below -100°C | Use FFKM + metal bellows hybrid sealing system |

| Pressure-Induced Deformation | Float chamber deformation >0.3mm at 25MPa | Increase wall thickness to 8mm, apply pre-stress reinforcement |

| Electromagnetic Interference | Magnetic field >100mT near electric arc furnaces | Add μ-metal magnetic shielding, attenuation ≥90% |

5. Conclusion and Outlook

Magnetic level indicators continue to evolve through innovations in materials, structural design, and smart functionality. Their ability to operate reliably in extreme environments—ranging from deep-sea oil extraction to nuclear power plants—makes them indispensable for the future of industrial monitoring.

Future R&D will focus on:

Breaking the 500°C thermal limit

Enhancing AI-based predictive diagnostics

Improving lifecycle reliability under severe process fluctuations

By addressing these frontiers, MLIs will offer robust, cost-effective, and intelligent level measurement solutions across even the harshest operating environments.