An electromagnetic flowmeter uses the principle of electromagnetic induction through an applied magnetic field to measure the flow of conductive fluids through an electromotive force. Simply put, an electromagnetic flowmeter is an instrument used to measure the flow of fluid-like materials with conductive properties. Once calibrated by water, the electromagnetic flowmeter can measure the flow rate of other conductive fluids.

During the period of electronic technology in the 1950s to the 1960s, an electromagnetic flowmeter was developed. It has since been modified and recreated to fit each technological development in recent times. It is used in several industries like the oil industry and can measure fluid like milk, chemical, slurry, acid, etc.

A high-concentration salt in water solution, Brine fluid is another important fluid measured with an electromagnetic flowmeter. It is a salt solution of between 3.5% to 26% salt solution. Usually, the seawater ranges at 3.5%, and a typical saturated solution is 26% but this might vary in different research due to temperature changes.

Naturally, brine is formed when ground saline water undergoes evaporation, but it is commonly generated from the mining of sodium chloride. It is used to de-icing the road in the food, oil, textile, and technology industry. As a by-product of these industries, it is used in freshwater recovery and desalination. It is also used as a preservative in refrigeration and cooling systems. It is used as heat-transfers media and used to cool steel.

Brine can be gotten from sedimentation basins, seawater, shallow groundwater below the fresh and saline waters, geothermal brines, and industrial brine from dairy, leather, textile, and oil industries. Brine gotten from sedimentation basins has varying stratification conditions and can be grouped into intersaline (majorly sodium brines), hypersaline (multicomponent brines), and hyposaline brines (multicomponent brines).

Brine mining is a process that involves the extraction of useful resources or materials dissolved in brine. These materials could either be compounds or elements and are extracted from underground brine through brine mining.

Brine mining is a safer method for dissolved minerals when compared to waste minimization and resource recovery. It is important to note that brine mining differs from in-situ leaching and solution mining. The latter involves water or chemicals being added to dissolve materials (solid-state) before extraction, unlike brine mining whose materials have naturally dissolved.

Underground brine is the raw material from which all naturally formed brine and many chemical elements like calcium, lithium, iodine, bromine, potassium, cesium, strontium, boron, lithium, magnesium, and rubidium are obtained. Underground brine is also the source of our common salt and therapeutic brine baths. These materials can be reused.

Based on how predominant an anion is, underground brine can be grouped into sulfate, chloride, or hydrocarbon, and out of the three, only the chloride brines are largely found. The chloride brine is made up of magnesium, calcium, and sodium brines.

Why are Electromagnetic Flowmeters Used to Measure Underground Brine?

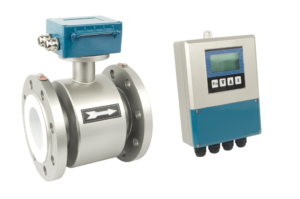

- With a sensor structure as handy and relatively simple, the electromagnetic flowmeter consumes low power while in use. Because it has no parts in motion, the flow sensor measuring tube produces no additional pressure loss that could occur due to the tube passing through the brine fluid or any other type of medium.

- Electromagnetic flowmeters can accurately measure the flow rate of a corrosive medium, suspended liquid-solid medium of two-phase flow, sloping medium, and clear fluid like brine. Why? There are no obstructions in the flow component of the metering tube. The electrode and the measuring tube lining are the only parts of the electromagnetic flowmeter that encounter the fluid to be measured. An added advantage is that the materials of the measuring tube and electrodes can be changed according to the type of fluid to be measured.

- A general advantage of the electromagnetic flowmeter is that it can measure flow in a reversible and forward direction. It is also a more suitable instrument for measuring volume flow, and the density, temperature, and viscosity of the fluid being measured (underground brine) does not affect its readings.

- The range of the electromagnetic flowmeter can read 100:1, i.e., its output: the average flow velocity of the fluid. With a range, this wide, brine fluid pumped out from the underground can be measured accurately. This includes its independence over a turbulent state in a balanced distribution.

- Measuring brine flow rates is more cost-effective with the use of a flowmeter. Brine varies due to the different extraction processes and their area of extraction. Using a flowmeter is a more applicable way to tell their difference accurately. An example is differentiated between chloride brine and sulfate brine or hypersaline and hyposaline brine.