Electrolytic copper foil, a fundamental material in electronics manufacturing, is known as the “neural network” for signal and power transmission in electronic products, primarily used in producing printed circuit boards and lithium batteries. Recently, the demand for copper foil has surged due to the growth of the lithium-ion battery industry, leading to rapid development in the copper foil sector.

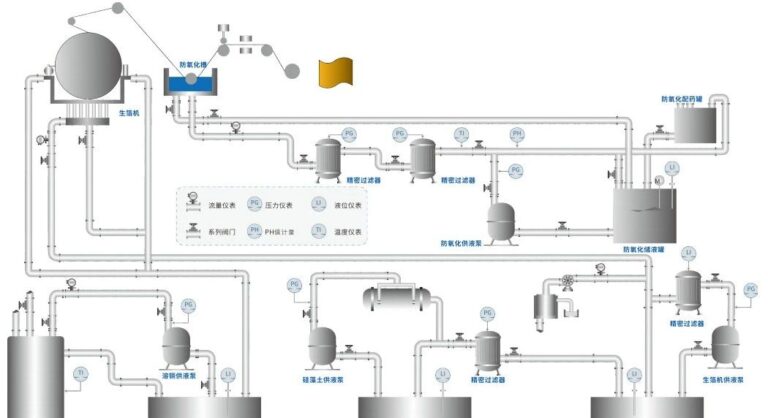

Electrolytic copper foil is produced by depositing copper ions from the electrolyte onto a rotating stainless steel or titanium cathode drum. Most domestic production uses a continuous drum cathode with insoluble anodes for electrolytic copper foil. The process includes copper dissolution in the electrolyte, filtration and purification, primary foil generation, roughening, plating with different metals, anti-oxidation treatment, cutting, and packaging.

Throughout this production process, multiple electromagnetic flow meters monitor the electrolyte flow at different stages. For example, these meters precisely control the injected volume during electrolyte injection, monitor flow changes before and after filtration in the circulation system, and provide real-time monitoring of electrolyte flow during electrolysis to ensure stability and high-quality copper foil production.

A copper foil project by a Shanxi-based company required replacing foreign-made flow measurement instruments with domestic ones. This involved several stages, including the copper dissolution phase, electrolyte pump systems, and various stages in the production line where multiple flow meters are installed. Due to the complex nature of the processes, the customer had specific requirements:

- Accurate measurement of dissolution liquids with corrosion resistance and stable performance.

- Flexible output options for different measurement points.

- Instruments that meet safety standards for production.

Solution

Given the customer’s previous issues with measurement accuracy and frequent instrument failures, engineers conducted an on-site survey to analyze the characteristics of the media at different points. For each location, suitable electrodes and linings were selected for the electromagnetic flow meters based on the media’s properties. Given that the temperature of the sulfuric acid and copper medium in the pipeline ranges around 50°C and can drop to 20°C during shutdown or cleaning, the team selected specific lining materials with cast and hygienic-grade linings with internal steel mesh to prevent deformation due to negative pressure.

To meet various output requirements at different points, the replacement flow meters used a 4-20mA output with HART communication, 24VDC power supply, and a dedicated 15-meter cable. Due to the high-power equipment and complex electromagnetic environment on-site, the engineers optimized the flow converter’s design to ensure electromagnetic compatibility, including resistance to fast transients, electrostatic discharge, and magnetic field interference.

The customer provided positive feedback, adopting 687 of the company’s electromagnetic flow meters for the new project. This improvement significantly enhanced measurement accuracy, reliability, and stability, which in turn improved product quality and production efficiency.

Product Recommendations for On-Site Application

The LDG series electromagnetic flow meter, specially designed for measuring corrosive media, is recommended for this application. With electrodes made from corrosion-resistant materials, this flow meter effectively withstands strong corrosive fluids such as copper sulfate. Its unique structure supports negative pressure resistance, making it an ideal metering product for the copper foil manufacturing industry.

Product Features:

- Measurement error within ±0.5%.

- Minimum flow rate below 0.3 m/s.

- Multiple signal output options for ease of use and installation without straight pipe sections.

- Ultra-low network loss, conserving energy and reducing consumption.