1. Overview of APL Two-Wire Ethernet Technology

Definition and Principle

APL (Advanced Physical Layer) is an Ethernet-based physical layer technology specifically designed for the process automation industry. It uses only two wires for both power supply and data communication, enabling safe and reliable operation even in hazardous areas.

APL employs advanced modulation and encoding techniques, such as Manchester encoding, to transmit digital signals over the two-wire cable. These techniques enhance noise immunity and ensure stable signal transmission and interpretation.

Technical Features

Intrinsic Safety: APL complies with intrinsic safety requirements, allowing safe use in environments with explosive gases or dust. It limits energy transmission parameters (voltage, current, and power) to prevent ignition risks.

Long-Distance Transmission: APL supports communication distances of over 1000 meters, ideal for large-scale or distributed industrial facilities.

High Bandwidth and Real-Time Performance: It meets the high data throughput and low latency demands of SIS for real-time sensor data and control instructions.

Strong Anti-Interference Capability: The encoding and signal processing provide robust protection against electromagnetic and RF interference, which is common in industrial environments with motors and drives.

2. Introduction to Safety Instrumented Systems (SIS)

Definition and Function

SIS are independent protection systems that safeguard industrial processes by detecting hazardous conditions and initiating automated responses, such as emergency shutdowns or alarms. They are separate from the Basic Process Control System (BPCS) and are critical in mitigating accident risks.

Safety Integrity Levels (SIL)

SIS design follows international standards such as IEC 61508 and IEC 61511, which define four Safety Integrity Levels (SIL 1 to SIL 4). Each level corresponds to the probability that a system can perform its safety function correctly upon demand. Higher SIL levels require more stringent design, testing, and maintenance protocols.

3. APL Technology in SIS Applications

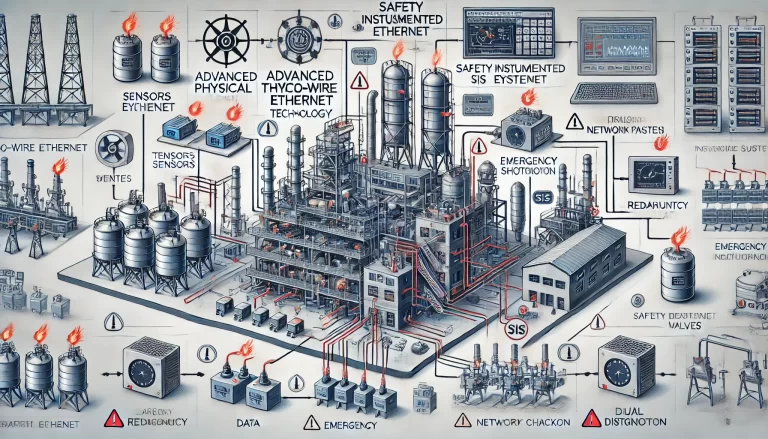

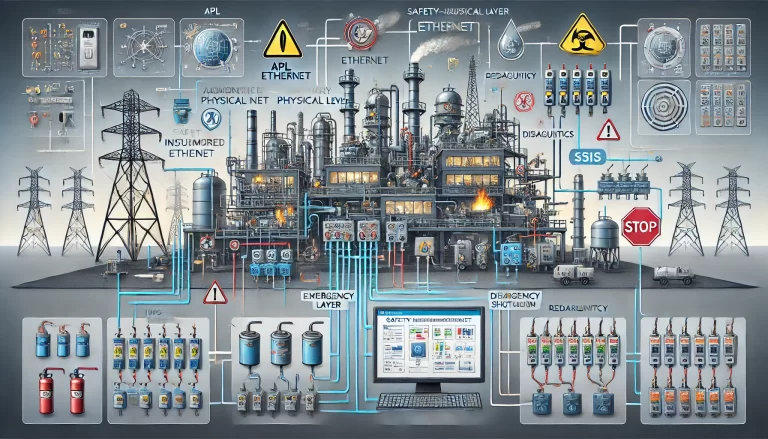

Sensor and Actuator Integration

Data Acquisition: APL enables high-speed and reliable data acquisition from temperature, pressure, and level sensors to the SIS controller. For example, in a chemical reactor, real-time temperature data can be transmitted to determine whether to initiate a shutdown.

Actuator Control: APL can accurately deliver control signals to actuators such as emergency shutoff valves. During hazardous conditions, it ensures timely actuation to isolate hazardous material flows.

System Communication and Network Architecture

Distributed Architecture: APL supports decentralized SIS architectures, connecting equipment across multiple plant areas to a central monitoring station.

Redundancy and Fault Tolerance: Dual-path network designs using APL enhance communication reliability. If one path fails, the system automatically switches to a backup route, maintaining uninterrupted operation.

Enhancing SIS Reliability and Security

Fault Detection and Diagnostics: APL provides real-time monitoring of line status, including open/short circuits and signal degradation, supporting fast maintenance and troubleshooting.

Data Integrity and Security: APL integrates encryption and verification mechanisms to ensure data is not tampered with and that only authorized devices can access the system.

4. Application Case Studies

Case 1: Chemical Plant Operations

In a large chemical plant, APL connects multiple sensors and emergency valves. During a reactor temperature spike caused by a cooling system failure, the sensor data was instantly transmitted via APL. The SIS controller triggered an emergency shutdown within milliseconds, preventing a potential explosion.

Case 2: Offshore Oil and Gas Platform

On offshore platforms where safety standards are stringent, APL links pressure and level sensors with critical safety systems. In a blowout scenario, APL-enabled devices rapidly transmit data to initiate BOP (blowout preventer) actions and alert central monitoring centers, ensuring rapid emergency response.

5. Challenges and Future Outlook

Current Challenges

Compatibility Issues: Integration with legacy equipment from various brands may require adaptation, increasing engineering complexity.

Cost Constraints: The initial investment in APL-compliant devices and cabling can be high, potentially deterring adoption among smaller enterprises.

Standard Updates: Evolving automation and safety standards necessitate frequent updates and device compatibility enhancements.

Future Outlook

Technological Convergence: APL is expected to integrate with IoT and AI technologies for smarter device management and predictive safety analytics.

Expanded Adoption: As costs decrease and standards mature, APL will find wider use in sectors beyond chemicals and oil & gas, such as pharmaceuticals and food processing, where process safety is equally critical.

Conclusion APL two-wire Ethernet represents a major advancement in enabling high-reliability, intrinsically safe communication for SIS. Its long-range, high-speed, and secure data transmission capabilities align perfectly with the increasing complexity and safety demands of modern industrial processes.