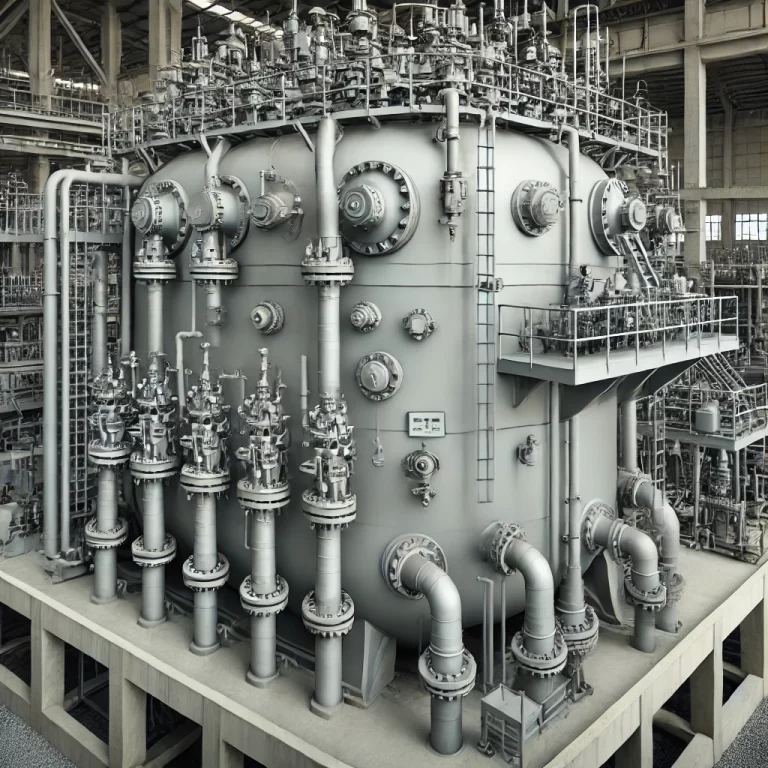

In environments involving complex chemical reactions and the mixing of various media, such as adipic acid mixing tanks, accurate level monitoring is crucial. In recent years, radar level transmitters have been widely applied to the measurement of levels in adipic acid mixing tanks due to their unique advantages.

Adipic acid, as an important chemical raw material, requires storage and reaction in mixing tanks during its production. The media inside the tanks often exhibit diversity and complexity, potentially including different types of liquids, solid particles, or powders. These media vary in physical properties (such as density, viscosity, and dielectric constant) and chemical characteristics (such as corrosiveness and reactivity), posing significant challenges for level measurement.

Key Challenges in Adipic Acid Tank Level Measurement:

- Multiple Liquid Phases: Adipic acid mixing tanks often contain multiple liquid layers, which traditional level transmitters struggle to distinguish and measure accurately.

- Large Level Fluctuations: During mixing and reactions, the liquid level in the tank may change dramatically, requiring transmitters with rapid response capabilities and high measurement accuracy.

- Corrosive Media: Some media may be corrosive to the transmitter’s materials, affecting measurement precision and service life.

Advantages of Radar Level Transmitters:

Radar level transmitters, which operate based on time-of-flight principles, transmit electromagnetic waves and receive the echoes reflected from the material’s surface to measure the level. The time difference between transmission and reception is converted into a level signal, achieving precise height measurement.

Specific applications in adipic acid mixing tanks include:

- Accurate Level Monitoring: Radar level transmitters provide real-time, accurate monitoring of the tank’s level, offering reliable data for process control and adjustments.

- Detection of Multiple Liquid Interfaces: With appropriate model selection and parameter settings, radar level transmitters can accurately detect the interfaces of different liquid layers, allowing precise multi-phase level measurement.

- Handling Large Level Variations: Due to their high measurement speed and responsiveness, radar level transmitters can quickly capture significant level changes in the tank, ensuring measurement accuracy and reliability.

- Resistance to Corrosive Media: Radar transmitters are constructed using corrosion-resistant materials for the antenna and casing, effectively resisting damage from corrosive substances like adipic acid.

- Remote Monitoring and Data Transmission: They support remote monitoring capabilities, allowing measurement data to be transmitted to control systems or upper-level computers for real-time monitoring and data analysis.

Case Study:

A chemical plant’s adipic acid production line utilized radar level transmitters for level measurement in its mixing tanks. The practical application showed that, compared to traditional level transmitters, radar transmitters demonstrated significant advantages in measurement accuracy, stability, and reliability:

- Improved Measurement Accuracy: The error of radar transmitters is controlled within ±1mm, much lower than the error range of traditional transmitters, enabling more precise level monitoring and optimization of production control strategies.

- Reduced Maintenance Costs: The non-contact measurement method and strong corrosion resistance minimize the need for maintenance and component replacement, significantly lowering maintenance costs and labor intensity.

- Enhanced Production Efficiency: Accurate real-time level monitoring data helps the plant promptly adjust production parameters and control strategies, thereby improving production efficiency and product quality while reducing downtime and safety risks caused by level anomalies.

In summary, radar level transmitters, with their high accuracy, rapid response, strong adaptability, and non-contact measurement capabilities, demonstrate significant advantages and application value in level measurement for adipic acid mixing tanks.