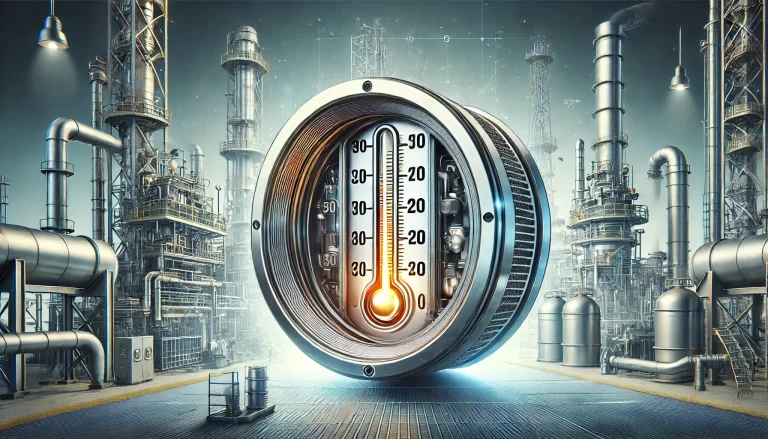

Bimetallic thermometers are widely used in industrial and commercial applications due to their durability, accuracy, and reliability. To ensure proper performance and longevity, the external appearance of a bimetallic thermometer must meet specific standards. This article outlines the key appearance requirements that should be adhered to when manufacturing or inspecting a bimetallic thermometer.

1. Structural and Exterior Design

A high-quality bimetallic thermometer should exhibit a well-designed structure with no visible defects. The essential structural and exterior requirements include:

Dial Face Clarity: The dial face should be clear and legible, with evenly spaced graduations and distinct numerals. The temperature scale should be well-printed and resistant to fading or wear over time.

Casing Integrity: The outer casing must be free of any dents, cracks, or deformations. It should be smooth to the touch, with no sharp edges or rough spots that could pose a safety risk.

Material Quality: The casing is typically made from stainless steel or other corrosion-resistant materials. The chosen material should be appropriate for the intended application environment, such as high-temperature, corrosive, or outdoor conditions.

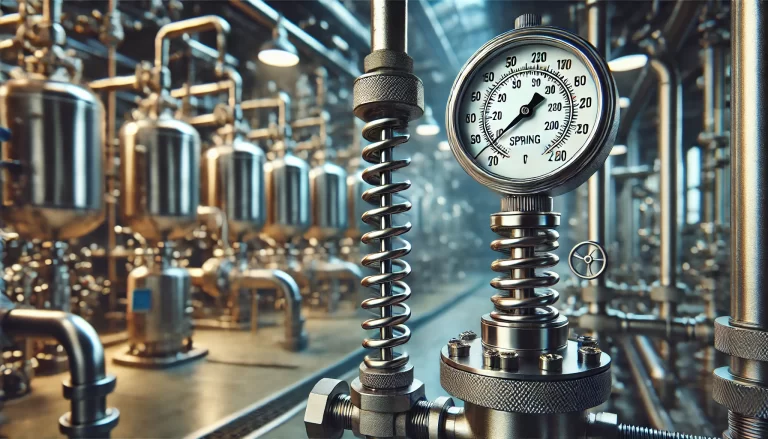

Pointer Condition: The pointer should be securely mounted, free of bends or misalignments, and capable of moving smoothly without obstruction. It should not be loose or stuck at any position.

2. Glass and Protection Features

The protective cover over the dial plays a critical role in maintaining the readability and longevity of the thermometer. The appearance and quality of this component must meet the following criteria:

Transparency: The cover glass (or plastic) must be clear and free from bubbles, scratches, or cloudiness that could hinder readability.

Sealing Quality: The glass must be tightly sealed to prevent dust, moisture, or foreign particles from entering the dial face. An improper seal can lead to condensation buildup, which obscures visibility and may damage internal components.

Impact Resistance: If designed for harsh environments, the glass should be made of shatter-resistant material such as reinforced glass or durable plastic.

3. Identification and Labeling

A well-marked bimetallic thermometer ensures correct usage and traceability. The following labeling features must be present and in good condition:

Model and Specification Markings: The thermometer should have clear, non-fading labels indicating the model, measuring range, and division value.

Unit of Measurement: The temperature unit (°C, °F, or dual-scale) should be explicitly marked and legible.

Manufacturer Information: The manufacturer’s name, logo, or serial number should be printed or engraved on the body to ensure traceability.

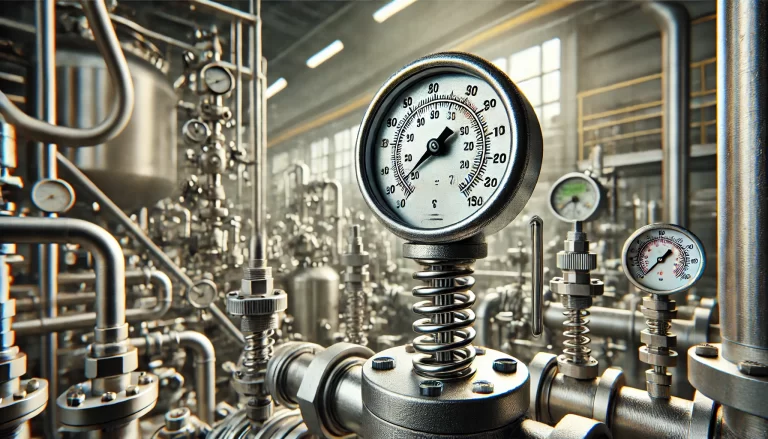

4. Mechanical Components and Probe Condition

The functional parts of a bimetallic thermometer, such as the sensing probe and mounting threads, should meet strict appearance requirements:

Probe Surface Quality: The probe should be free of scratches, deformations, or oxidation. It must have a smooth and uniform surface to ensure accurate temperature transfer.

Threaded Connection Integrity: If the thermometer includes a threaded connection for installation, the threads must be well-machined, free of burrs, and properly aligned to allow easy and secure attachment.

Mechanical Stability: The connection between the probe and the casing should be firm, with no visible gaps or looseness.

5. Functional Appearance and Responsiveness

Beyond its structural attributes, a bimetallic thermometer should visually demonstrate its ability to function correctly:

Zero Position Calibration: If the thermometer has an adjustable zero position, it should be correctly set with no signs of misalignment.

Smooth Needle Movement: The needle should move smoothly in response to temperature changes, without jerky or erratic motion.

No Visible Defects: There should be no visible contaminants, rust, or foreign objects inside the thermometer that could interfere with its operation.

Conclusion

A bimetallic thermometer’s appearance is a crucial factor in ensuring its accuracy, durability, and ease of use. By adhering to strict appearance requirements—including clear labeling, smooth surfaces, precise dial markings, and robust mechanical construction—manufacturers can produce high-quality thermometers suitable for a variety of demanding applications. Proper inspection and maintenance further ensure that these devices remain reliable throughout their operational lifespan.