With the continuous advancement of science and technology, radar level meters, as an advanced measurement technology, have been widely used in the industrial field.

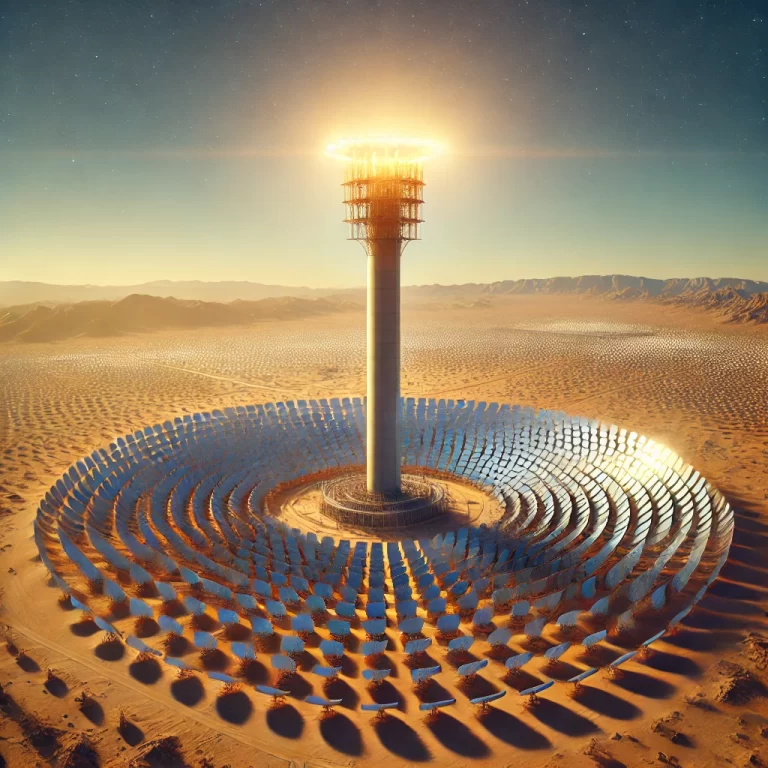

Especially in solar thermal power plants, the application of radar level meters not only improves the accuracy of monitoring, but also enhances the safety and efficiency of the production process.

This article will deeply explore the application of radar level meters in solar thermal power plants and the many benefits they bring.

Radar level meters measure the liquid or material level of a material by emitting electromagnetic waves and receiving their reflected waves. When the electromagnetic waves encounter the surface of the material, part of the wave is absorbed, while the other part is reflected back to the radar sensor.

By calculating the time it takes for the electromagnetic waves to go back and forth, the position of the material can be accurately calculated.

This non-contact measurement method enables it to work stably in harsh environments such as high temperature, high pressure, and strong corrosiveness.

In CSP power plants, radar level meters are mainly used to monitor the molten salt level in the molten salt storage tank. As a heat transfer medium, molten salt plays a vital role in CSP systems.

Therefore, real-time and accurate monitoring of the molten salt level is essential to ensure the stability and safety of system operation. Traditional level measurement methods, such as float or pressure sensors, are susceptible to corrosion in high-temperature molten salt environments, resulting in reduced measurement accuracy.

The radar level meter can measure without direct contact with the measured medium, greatly improving the accuracy and reliability of the measurement.

By continuously monitoring the level of the molten salt tank, operators can adjust system parameters in a timely manner, optimize the circulation and heat distribution of the molten salt, and thus improve the energy efficiency of the entire CSP system.

If the molten salt overflows or leaks, it may cause serious safety accidents. The radar level meter can monitor the level changes in real time, and once an abnormality is detected, it can immediately alarm to effectively prevent accidents.

Since the radar level meter does not need to contact the measured medium, it reduces the wear and maintenance frequency of the equipment, extends the service life of the equipment, and thus reduces the operation and maintenance costs.

The application of radar level meter in CSP power plant demonstrates its excellent performance in the field of industrial measurement.

By providing high-precision and high-reliability liquid level monitoring, radar level meter not only optimizes the operating efficiency of CSP system, but also enhances the safety performance of the system, thus ensuring the long-term stable operation of CSP power plant.