De-dusting ash level measurement is one of the most common and important applications in industrial environments. As a reliable measuring device, a radar level meter plays an important role in dust ash level measurement. This paper will introduce the difficulties of radar level meters to measure dust ash and give a practical measurement case to illustrate the feasibility and effectiveness of its application.

Difficulties in dust ash level measurement, and dust interference In dust removal equipment, whether electrostatic precipitators, bag filters, or centrifugal precipitators, large amounts of dust are generated. This dust is dispersed in the environment and interferes with the transmission and reception of radar signals, thus affecting the accurate level measurement.

The scattering, absorption, and reflection properties of dust can cause the radar measurement signal to suffer from attenuation and distortion. High-temperature environment In the dust removal process, there are often high-temperature conditions in the industrial environment.

High temperatures not only cause certain effects on the radar equipment itself but also increase the difficulty of measurement. Thermal expansion of the metal reflecting surface and signal attenuation problems in high-temperature environments can make level measurement more complicated. Impurities or particle changes in the composition and properties of the dust removal ash may change over time during the dust removal process.

Changes in the composition of impurities and particles can have an impact on the level measurement and cause errors. In addition, changes in the shape, size, and density of the particles can also have an effect on the measurement results.

A coal-fired power plant chose to use radar level meters in order to monitor the level of dust ash in the dust collector and to adjust and control the handling of the dust in a timely manner.

However, they faced some challenges due to the presence of large amounts of dust in the environment and interference from factors such as high temperatures and particle variations.

To address these challenges, they took the following measures: Equipment location optimization: Determine the best location for the radar level meter to be installed so that it is not directly exposed to dust-ejected areas.

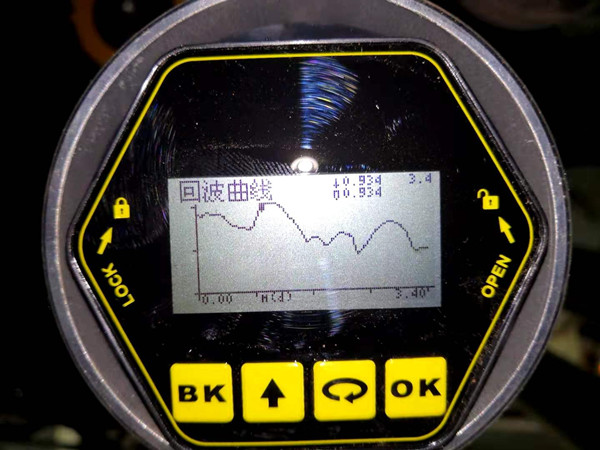

Also, ensure that the radar equipment is away from high-temperature sources to reduce the interference of temperature on the measurement. Signal processing technology: Select a radar level meter with advanced signal processing technology that can accurately identify and compensate for the impact of dust interference on the measurement signal. Improve the measurement accuracy through measures such as signal filtering and algorithm optimization.

Regular maintenance and calibration: Regular maintenance and calibration of the radar level meter include cleaning the sensors, checking the status of the equipment, and updating the calibration parameters. This helps keep the equipment working properly and the measurements accurate.

Through the above measures, the power plant successfully solved the difficult problem of dust ash level measurement. They obtained accurate and stable level data and were able to process and control the data in a timely manner, improving the efficiency of dust ash handling and production safety.

Although dust ash level measurement faces some difficulties, radar level meters, as a reliable measurement device, can overcome these challenges by optimizing the meter location, signal processing techniques, and regular maintenance.