1. Introduction

Temperature transmitters play a crucial role in the field of industrial automation and instrumentation. Unlike sensors, which simply convert physical quantities into electrical signals, transmitters further process and amplify these signals, ensuring accurate and reliable measurements. A common issue that users may encounter with temperature transmitters is a “no output” condition. This article analyzes the possible reasons for this issue and provides troubleshooting methods to help users effectively diagnose and resolve it.

2. Function of Temperature Transmitters

2.1 Amplification and Signal Processing

Temperature transmitters not only convert temperature variations into measurable electrical signals but also amplify and process these signals for transmission over long distances with minimal loss. There are different types of temperature transmitters, including:

Thermocouple Temperature Transmitters: These devices consist of a reference source, cold junction compensation, amplification unit, linearization circuit, voltage-to-current (V/I) conversion, open-circuit protection, reverse polarity protection, and current limiting circuits. They convert the thermoelectric potential generated by the thermocouple into a linear 4–20mA current signal.

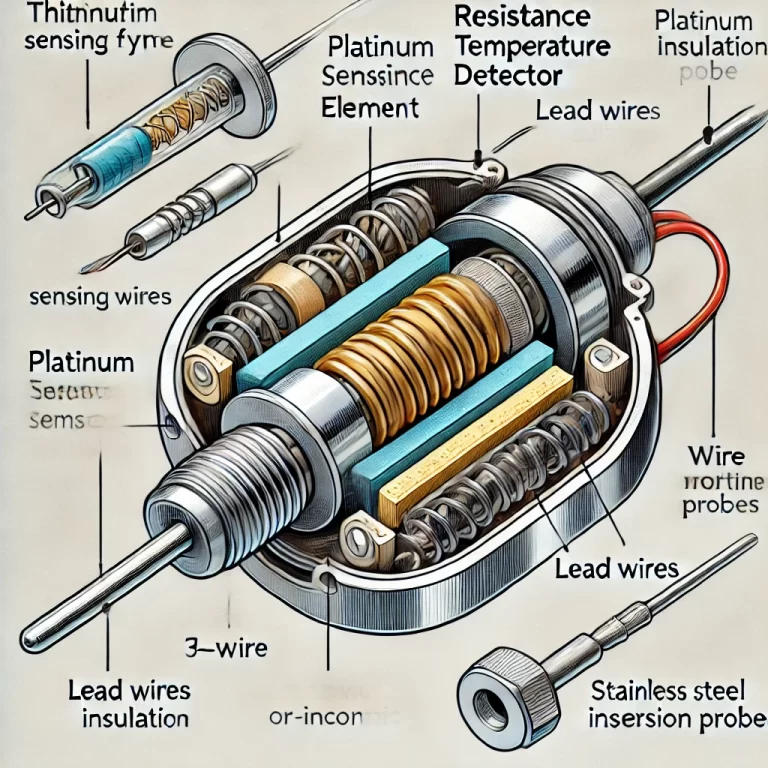

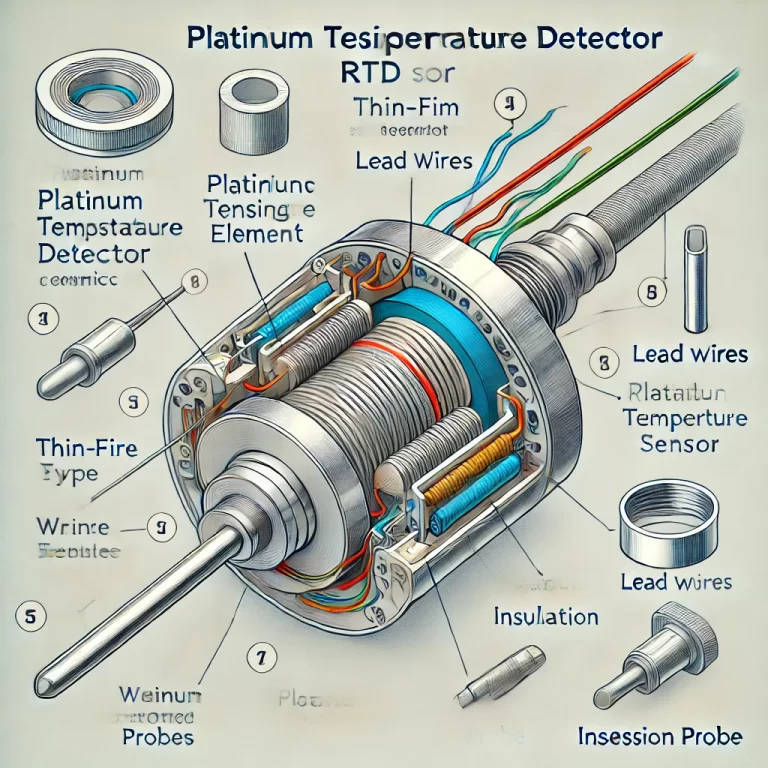

Resistance Temperature Detector (RTD) Transmitters: Comprising a reference unit, resistance-to-voltage (R/V) conversion unit, linearization circuit, reverse polarity protection, current limiting protection, and V/I conversion unit, these transmitters process RTD resistance changes and output a corresponding 4–20mA signal.

Integrated Temperature Transmitters: These combine a temperature sensor (thermocouple or RTD) and a two-wire electronic module into a single compact unit. They are widely used for easy installation and reliable performance in various industrial applications.

2.2 Role in Temperature Measurement

Temperature transmitters serve as an essential bridge between temperature sensors and control systems. Their primary functions include:

Signal Standardization: Converting thermocouple millivolt signals or RTD resistance variations into a standardized 4–20mA output signal.

Remote Monitoring & Control: Feeding signals into display and recording instruments for real-time monitoring.

Automation Integration: Providing input to controllers to form an automatic temperature regulation system.

Computerized Data Processing: Feeding data into computers for real-time analysis, trend monitoring, and automated control in industrial processes.

3. Common Causes of No Output in Temperature Transmitters

A temperature transmitter failing to output a signal is a common issue, but in most cases, proper troubleshooting can identify and resolve the problem. Below are the main reasons for such failures:

3.1 Power Supply Issues

Incorrect Polarity Connection: Ensure the power supply wires are connected correctly (positive to positive, negative to negative). Reverse polarity may cause the transmitter to malfunction or not operate at all.

Insufficient Power Supply Voltage: Measure the power supply voltage to confirm it provides at least 24V DC. The voltage at the transmitter input terminal should be at least 12V DC to function properly.

Faulty Power Source or Wiring Issues: Check for broken wires, loose connections, or poor-quality power sources. If power is not reaching the transmitter, inspect the wiring circuit.

3.2 Circuit & Load Resistance Issues

Excessive Load Resistance: If the connected measuring instrument (e.g., PLC, recorder) has an input impedance greater than 250Ω, it may prevent proper current flow and result in no output.

Broken Circuit: If any component in the current loop (e.g., wires, connections) is damaged or disconnected, the circuit will be open, preventing signal transmission.

Incorrect Instrument Selection: Ensure that the receiving device is correctly configured to accept a 4–20mA input signal and that its impedance does not exceed the transmitter’s maximum output capability.

3.3 Sensor & Internal Component Failures

Faulty Sensor (Thermocouple/RTD): If the temperature sensor is damaged or improperly connected, the transmitter cannot generate an output signal. Verify the sensor’s resistance or voltage output with a multimeter.

Broken Internal Circuitry: If the transmitter’s internal circuits, such as the signal amplifier or conversion unit, are damaged, there may be no output. In such cases, replacing the transmitter may be necessary.

Environmental Damage: Exposure to excessive moisture, extreme temperatures, or chemical contaminants can cause internal damage, affecting performance.

3.4 Display Malfunctions (If Equipped)

Defective Built-in Display: Some transmitters have digital displays. If the display is not working, check whether it is receiving power.

Faulty Display Connection: If a transmitter has an external display unit and the output signal appears normal, but the display does not show readings, try bypassing or replacing the display.

3.5 Misconfigured or Malfunctioning Transmitter

Incorrect Configuration Settings: Some smart temperature transmitters require configuration using specialized software or DIP switches. Ensure the settings match the required temperature range and sensor type.

Firmware or Calibration Issues: Some advanced transmitters require periodic calibration. If calibration is incorrect, it may result in zero output.

4. Troubleshooting Steps

If your temperature transmitter has no output, follow these systematic troubleshooting steps:

Check Power Supply:

Verify that the power supply voltage is sufficient and correctly connected.

Ensure no loose or broken wires exist.

Test Circuit Continuity:

Use a multimeter to measure loop resistance and verify that it falls within acceptable limits.

Check that all devices in the loop are properly connected.

Inspect the Sensor:

Measure the sensor’s resistance (for RTDs) or voltage (for thermocouples) to confirm it is functional.

Replace the sensor if readings are inconsistent or abnormal.

Check the Transmitter’s Internal Components:

If possible, test with a known working transmitter to isolate the issue.

If internal circuits are suspected to be damaged, contact the manufacturer for repair or replacement.

Verify Configuration & Settings:

Ensure the transmitter is correctly configured for the sensor type and measurement range.

If applicable, reset the transmitter to default settings and reconfigure.

Inspect Environmental Conditions:

Look for signs of moisture ingress, extreme heat, or corrosive exposure that may affect performance.

If environmental factors are causing failures, consider protective enclosures.

5. Conclusion

Temperature transmitters are essential for accurate and reliable temperature measurements in industrial applications. However, they can experience output failure due to power issues, circuit malfunctions, sensor faults, configuration errors, or environmental factors. By following a structured troubleshooting process, users can identify and resolve most issues efficiently. In cases where internal components fail, it is best to contact the manufacturer for further support or replacement.