Introduction

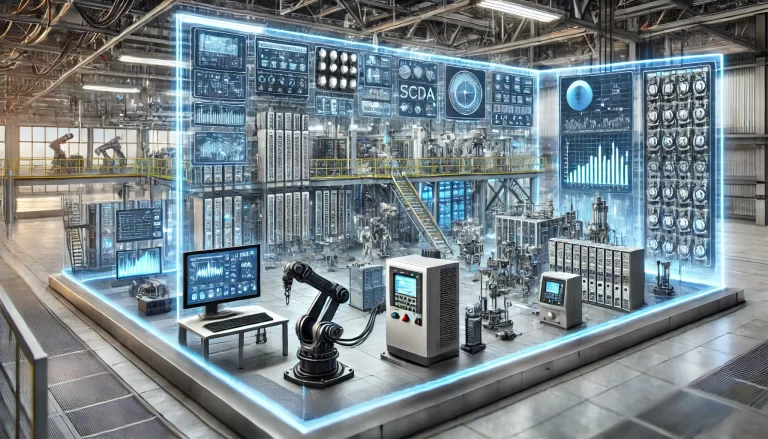

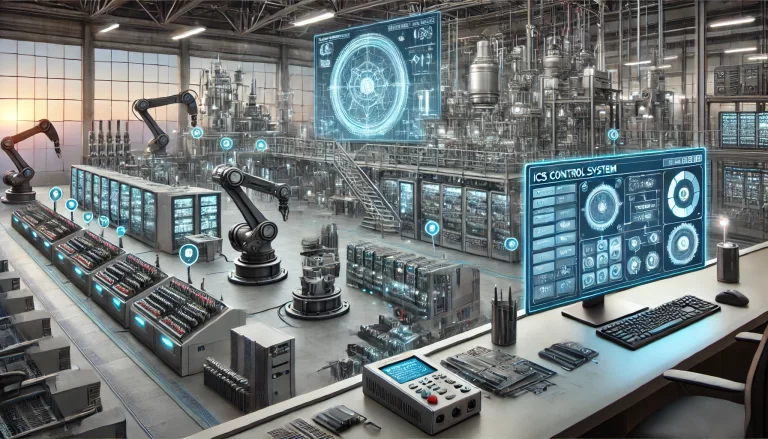

Industrial Control Systems (ICS) play a critical role in monitoring and controlling equipment and processes in various industrial environments. These systems are indispensable in industries such as manufacturing, energy, transportation, and infrastructure, ensuring efficiency, quality, and safety. The core of ICS involves technologies and components like Programmable Logic Controllers (PLC), Supervisory Control and Data Acquisition (SCADA) systems, and Distributed Control Systems (DCS).

This article explores the fundamental concepts of ICS, its key components, operational principles, security challenges, and strategies for effective management. To provide additional clarity, we will include practical examples, visual aids, and an outlook on future trends.

1. Understanding the Basics of ICS

Industrial Control Systems refer to a broad category of automation systems designed to control industrial processes. These systems integrate hardware, software, networks, and protocols to oversee the operation of machines and systems within industrial facilities.

Key Examples:

PLC: Controls robotic arms on production lines.

SCADA: Manages pumps and valves in a water treatment plant.

The primary objective of ICS is to ensure the safe and efficient operation of industrial processes through real-time data collection, analysis, and control.

Types of ICS:

Distributed Control Systems (DCS): Used in complex, continuous processes like chemical plants and oil refineries.

SCADA Systems: Suitable for geographically dispersed systems such as energy grids and transportation.

PLC Systems: Focused on localized, discrete automation tasks.

2. Core Components of ICS

2.1 Programmable Logic Controllers (PLC)

PLC is a robust industrial computer designed to perform real-time control tasks. It collects data from input devices (e.g., sensors) and executes control commands via output devices (e.g., actuators).

Advantages:

High reliability.

Strong resistance to environmental interference.

Flexibility in programming and scalability.

Application Example: A PLC on a car manufacturing line controls robotic welders, ensuring precision and safety.

2.2 Supervisory Control and Data Acquisition (SCADA)

SCADA systems oversee large, distributed networks and are vital in sectors like power distribution and transportation.

Components:

Sensors: Collect real-time data.

Remote Terminal Units (RTUs): Transmit data to the control center.

Human-Machine Interfaces (HMIs): Allow operators to visualize and control processes.

Application Example: A SCADA system in a power grid monitors transformer loads and adjusts output to maintain system balance.

2.3 Distributed Control Systems (DCS)

DCS is designed for processes requiring continuous control. It distributes control tasks among multiple local control units.

Key Features:

Redundancy for fault tolerance.

High precision in process control.

Application Example: A DCS in a chemical plant regulates temperature and pressure for optimal reactions.

2.4 Sensors and Actuators

Sensors: Measure variables like temperature, pressure, and flow.

Actuators: Perform physical actions like opening valves or starting motors.

Example: In an HVAC system, temperature sensors detect room conditions, and actuators adjust airflow to maintain comfort.

3. How ICS Works

The operational workflow of ICS typically involves three key stages:

Data Acquisition: Sensors capture real-time process data (e.g., flow rate of a liquid in a pipeline) and send it to controllers.

Data Processing and Decision-Making: Controllers analyze data using algorithms like PID control to determine necessary actions.

Command Execution: Actuators execute commands (e.g., increasing the pump speed to match the desired flow rate).

A Visual Example: Imagine a brewery. Sensors measure temperature during fermentation, and the PLC adjusts cooling systems to ensure the yeast operates within optimal conditions.

4. Security Challenges in ICS

As digitalization and the Industrial Internet of Things (IIoT) advance, ICS systems are increasingly interconnected, creating new vulnerabilities. Historically, ICS were isolated from external networks, but integration with IT systems has exposed them to cyber threats.

Common Security Risks:

Malware Attacks: E.g., the infamous Stuxnet attack targeting PLCs.

Physical Sabotage: Tampering with critical sensors or actuators.

Data Breaches: Unauthorized access to operational data.

Mitigation Strategies:

Network Segmentation: Isolating ICS from external networks.

Authentication Mechanisms: Multi-factor authentication for system access.

Encryption: Securing communication between devices.

Regular Audits: Periodic reviews to identify and rectify vulnerabilities.

5. Future Trends in ICS

Adoption of IIoT:

Enhanced interconnectivity between devices.

Real-time monitoring and predictive maintenance.

Digital Twins:

Virtual replicas of physical systems for simulation and optimization.

AI and Machine Learning:

Advanced analytics for decision-making.

Autonomous systems for dynamic process adjustments.

Increased Focus on Cybersecurity:

Development of ICS-specific security frameworks.

Greater collaboration between IT and operational teams.

Conclusion

Industrial Control Systems are the backbone of modern automation, ensuring seamless operation across industries. While the integration of advanced technologies is unlocking new possibilities, it also introduces complex challenges, especially in cybersecurity. By understanding ICS fundamentals and staying informed about emerging trends, organizations can harness the full potential of ICS while safeguarding their operations against potential threats.

Through continuous improvement and innovation, ICS will remain pivotal in driving industrial growth and resilience.