In industrial operations, safety is like a sword of Damocles hanging overhead — any negligence could trigger catastrophic consequences. One key defense mechanism widely adopted across industries is SIL, or Safety Integrity Level. But what exactly is SIL, and why is it so crucial? This article offers a detailed exploration of SIL’s definition, standards, applications, and certification process.

1. What Is SIL?

SIL, short for Safety Integrity Level, is a quantitative measure of a safety instrumented system’s (SIS) ability to perform its safety function under defined conditions and within a specified timeframe. It reflects the reliability of the SIS in preventing or mitigating hazardous events.

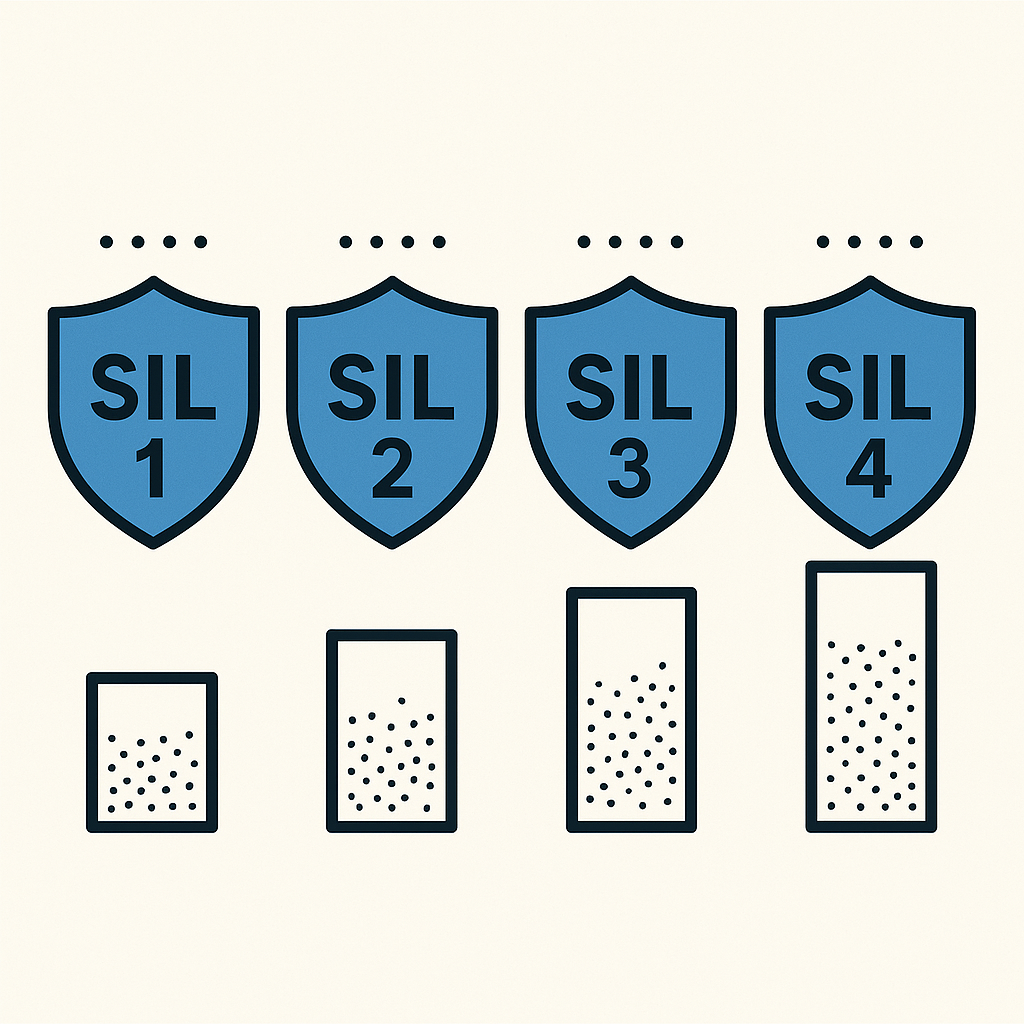

The IEC 61508 standard published by the International Electrotechnical Commission (IEC) defines four SIL levels:

| SIL Level | Probability of Failure on Demand (PFD) | Risk Reduction Capability | Typical Applications |

|---|---|---|---|

| SIL1 | 10⁻² to 10⁻¹ | Basic | Low-risk environments |

| SIL2 | 10⁻³ to 10⁻² | Medium | Common industrial processes |

| SIL3 | 10⁻⁴ to 10⁻³ | High | High-risk operations |

| SIL4 | < 10⁻⁴ | Very high | Mission-critical systems |

Higher SIL levels correspond to lower acceptable failure probabilities and greater risk reduction.

2. Key Standards for SIL

IEC 61508: Functional Safety of E/E/PE Safety-Related Systems

A general safety standard covering electrical, electronic, and programmable electronic systems. It outlines requirements across the system lifecycle, including design, development, operation, and maintenance.

IEC 61511: Functional Safety for the Process Industry

Derived from IEC 61508, this standard is tailored for process industries such as petrochemicals, pharmaceuticals, and food production. It details how to define safety functions, assess risks, and implement SIL-based SIS in complex environments.

ISO 26262: Functional Safety for Automotive Systems

A safety standard for electrical and electronic systems in the automotive industry. It ensures that systems like braking, steering, and engine control meet rigorous safety integrity requirements, especially important for autonomous and electric vehicles.

3. SIL Applications in Different Industries

Petrochemical Industry

In processes involving flammable, explosive, or toxic substances, high-SIL-rated SIS are essential. For example, during a chemical reaction, high SIL systems monitor temperature and pressure. If thresholds are exceeded, the system triggers emergency shutdown or pressure relief to prevent explosions or leaks.

Power Industry

In power plants, especially nuclear facilities, high SIL-rated systems control reactor power levels and prevent critical failures. In thermal and hydroelectric stations, SIL-rated relays detect faults and isolate circuits to ensure operational safety and grid stability.

Transportation

Aerospace: Flight control and engine management systems require SIL3–SIL4 compliance to handle failures in extreme conditions.

Rail: Signaling and braking systems depend on SIL-certified components to avoid collisions and enable safe emergency stops.

4. SIL Certification Process

← (Insert visual process flow)

Step 1: Define the Safety Requirements Specification (SRS)

Identify the SIS functions, operating conditions, and performance targets. For example, a chemical reactor SIS may require emergency cooling within 1 second if temperature exceeds 300°C.

Step 2: Risk Assessment

Use methods such as HAZOP, FTA, or FMEA to evaluate potential hazards, likelihood, and consequences.

Step 3: SIL Determination

Based on risk level, determine the appropriate SIL requirement using risk matrices or Layer of Protection Analysis (LOPA).

Step 4: System Design and Development

Develop hardware and software aligned with the required SIL level. Components such as sensors, logic solvers, and actuators must meet relevant reliability criteria.

Step 5: Verification and Validation

Conduct functional testing, code reviews, and failure simulations to verify that the system meets the SRS and SIL standard.

Step 6: Third-Party Certification

Accredited agencies (e.g., TÜV, EXIDA) audit the process and issue an official SIL certificate upon successful evaluation.

5. Why SIL Matters

✅ Protects Human Life

High SIL systems detect risks like gas leaks or overpressure early and activate alarms or shutdowns to prevent accidents and injuries.

✅ Safeguards Equipment and Environment

Reduces unplanned shutdowns, costly repairs, and environmental contamination from hazardous releases.

✅ Ensures Regulatory Compliance

Compliance with regional or industry-specific safety regulations (e.g., ATEX in the EU) often mandates SIL-rated systems for high-risk operations.

✅ Boosts Corporate Credibility

Having SIL-certified systems demonstrates commitment to safety, improves public image, and strengthens competitiveness in project bidding and partnerships.

Conclusion

SIL is more than a technical metric — it is the backbone of industrial safety. From petrochemicals to aerospace, implementing SIL-rated safety instrumented systems is a proactive approach to reducing risk, protecting lives, and maintaining operational integrity. As industrial automation and digitalization evolve, the importance of SIL will only continue to grow.