Introduction to PID Control

PID (Proportional-Integral-Derivative) control is one of the most widely used and effective control algorithms in engineering. Its popularity stems from its ability to address fundamental control system requirements: stability, responsiveness, and accuracy. Despite the emergence of modern control methods, PID remains at the core of most automation systems.

By tuning PID parameters, engineers can achieve a balanced trade-off among load handling, disturbance rejection, and system accuracy. This article outlines the fundamental principles and step-by-step procedures for PID parameter tuning, offering practical insights for beginners and experienced practitioners alike.

Why Is PID So Widely Used?

PID control addresses the fundamental challenges of control systems:

- Stability: Ensures the system remains steady under disturbances.

- Responsiveness: Allows quick adaptation to input changes.

- Accuracy: Minimizes the steady-state error, achieving close adherence to target values.

The inclusion of an integral term eliminates steady-state errors, while the derivative term predicts error trends, enhancing the overall system dynamics.

Fundamentals of PID Control

PID control combines three key components:

Proportional (P) Control:

- Adjusts the control output proportionally to the current error.

- Pros: Simple and immediate response.

- Cons: Steady-state errors may persist.

Integral (I) Control:

- Addresses steady-state errors by accumulating error over time.

- Pros: Eliminates steady-state errors.

- Cons: Can introduce oscillations if not tuned properly.

Derivative (D) Control:

- Reacts to the rate of change of the error.

- Pros: Predicts and reduces overshoots.

- Cons: Amplifies noise and may cause instability if overused.

The combined action of these three components ensures precise and efficient system behavior.

Open-Loop vs. Closed-Loop Systems

Open-Loop Control: The controller acts without considering the actual output. This system lacks feedback, which limits accuracy and adaptability.

Closed-Loop Control: Utilizes feedback to adjust the controller’s output. Negative feedback is preferred for stability, where the feedback signal counteracts the input signal.

PID Tuning Principles

Proper tuning ensures optimal performance. Below are key principles to follow:

Start with P-only Control:

- Remove I and D components (set Ti=0, Td=0).

- Gradually increase the proportional gain P until oscillations occur, then reduce it to 60–70% of that value.

Adjust the Integral Term (I):

- Start with a large integral time constant Ti, then gradually decrease it until the system oscillates. Set Ti to 150–180% of this value.

Add the Derivative Term (D):

- If needed, introduce Td. Gradually increase Td to reduce overshoot, ensuring the system remains stable. Typically, Td is set to 20–30% of the value where oscillations begin.

Iterative Fine-Tuning:

- Test the system under load and no-load conditions.

- Adjust parameters slightly to achieve desired performance.

Step-by-Step PID Tuning Procedure

1. Confirm Negative Feedback

Ensure the system uses negative feedback. For example, in a motor control system, increasing motor speed should result in a higher feedback signal.

2. Determine Proportional Gain (P)

- Remove Ti and Td.

- Increase P gradually from a small value. Stop when oscillations appear.

- Reduce P to 60–70% of this value.

3. Tune Integral Time Constant (T_i)

- Set Ti to a high value initially.

- Gradually reduce Ti until the system oscillates, then increase it to 150–180% of this value.

4. Fine-Tune Derivative Time Constant (T_d)

- Typically, set Td=0.

- If needed, gradually introduce Td to dampen overshoots, using 20–30% of the oscillatory limit value.

5. System Testing

- Test the system under varying conditions, such as load changes.

- Perform final adjustments to ensure stability, responsiveness, and accuracy.

Applications and Examples of PID Control

1. Industrial Examples

- Temperature Control: Ensures stable oven temperatures for consistent production quality.

- Pressure Regulation: Maintains stable pressures in pipelines.

- Flow Control: Accurately regulates fluid flow in chemical processes.

2. Practical Example

For a temperature control system:

- Start with P=50%, Ti=300 seconds, and Td=100 seconds.

- Gradually adjust based on the system’s response to achieve smooth temperature changes without overshoots.

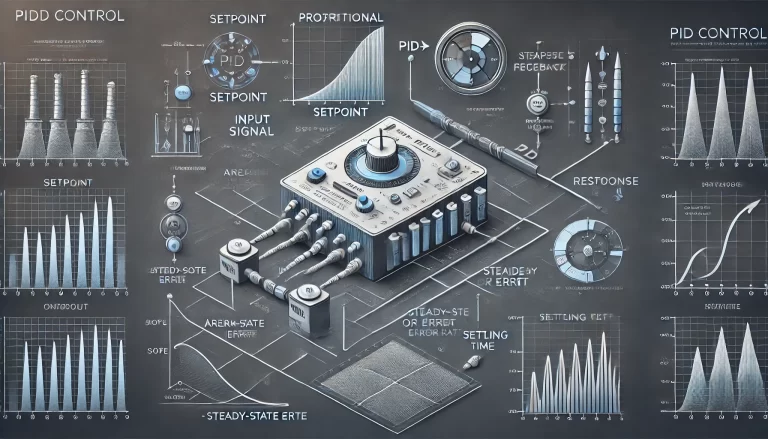

Visualizing PID Behavior

Adding charts and diagrams to demonstrate step responses under varying PID parameters can greatly enhance understanding:

- Step Response Graphs: Show the impact of P, I, and D on overshoot, settling time, and steady-state error.

- Tuning Workflow Diagrams: Highlight each step in the tuning process.

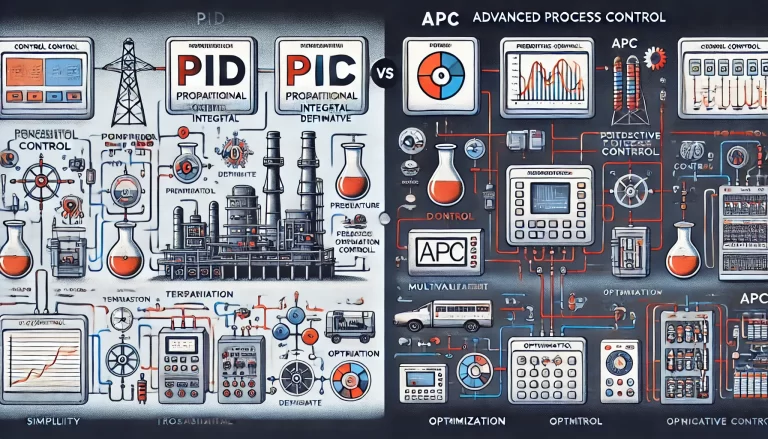

Advanced Topics

For complex systems, consider modern PID controllers with adaptive tuning and intelligent features. These controllers automatically adjust parameters based on real-time feedback, eliminating the need for manual tuning.

Conclusion

PID control is a cornerstone of automation, combining simplicity with robust performance. By understanding its principles and following structured tuning methods, engineers can achieve optimal system performance, even for diverse and complex processes.

With advancements in intelligent control systems, the adaptability and efficiency of PID control continue to expand its relevance in modern industry.