Level measurement is a critical component in industrial processes. Choosing the right level measurement technology is essential for improving operational efficiency, reducing maintenance costs, and ensuring safe operation. Three commonly used level measurement technologies are radar, ultrasonic, and capacitive technologies. Each has its advantages and disadvantages, making them suitable for different applications. This article will explore the working principles, advantages, disadvantages, and appropriate use cases of these technologies, and provide guidance on selecting the right technology for specific needs.

1. Radar Level Measurement Technology

Radar level sensors measure the level of a substance by emitting electromagnetic waves and analyzing the reflected signal. This principle is similar to radar systems used in the military and aviation sectors. The time taken for the signal to travel to the surface and return is used to calculate the distance between the sensor and the material.

Advantages:

- High Precision: Radar waves are not affected by the shape, density, temperature, or pressure of the material being measured, providing highly accurate readings.

- Versatile: It operates effectively in harsh environments, including high temperatures, high pressures, and corrosive settings.

- Non-contact Measurement: The sensor does not need to come into direct contact with the medium, preventing issues related to wear and contamination.

Disadvantages:

- High Cost: Radar sensors are more expensive to install and maintain compared to other technologies.

- Installation Space: Proper installation requires sufficient space and a clear line of sight for accurate signal reflection.

Applications:

- High-temperature and high-pressure environments (e.g., the petrochemical industry)

- Level measurement in corrosive substances (e.g., acids, alkalis)

- Storage tanks and silos where non-contact measurement is required

2. Ultrasonic Level Measurement Technology

Ultrasonic level sensors work by emitting sound waves and measuring the time it takes for the waves to return after hitting the material’s surface. The speed of sound varies depending on factors such as temperature, humidity, and the density of the gas in the environment, which can impact the accuracy of the readings.

Advantages:

- Low Cost: Ultrasonic sensors are typically more affordable than radar devices, making them a cost-effective solution for many applications.

- Ease of Installation: These sensors are non-contact and easy to install, especially in situations where accessibility may be limited.

- Suitable for Liquids and Solids: Ultrasonic technology is effective for measuring both liquid levels and solid materials, making it versatile for various industries.

Disadvantages:

- Environment Sensitivity: Ultrasonic measurements are influenced by environmental factors such as temperature, humidity, steam, and dust. These factors can degrade accuracy.

- Lower Accuracy: Compared to radar technology, ultrasonic sensors generally provide lower precision, especially in challenging environments.

Applications:

- Measuring levels of clean liquids in stable environments

- Level monitoring in silos and warehouses containing solid materials

- Environments with relatively stable temperature and humidity

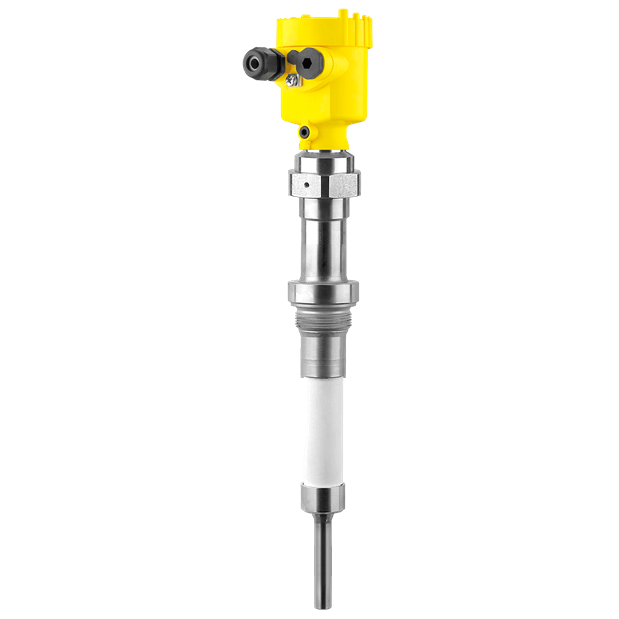

3. Capacitive Level Measurement Technology

Capacitive level sensors measure the change in capacitance as the level of the material changes. When the level of the medium rises or falls, the capacitance value changes, which is then converted into a level reading. Capacitive sensors offer high precision, particularly for liquids.

Advantages:

- High Precision: Capacitive sensors are highly accurate, particularly for measuring liquid levels, and can detect small changes in level.

- Wide Applicability: Suitable for measuring liquids, powders, and granular materials, capacitive sensors can be used in a variety of industries.

- Non-contact: Like ultrasonic sensors, capacitive sensors do not require contact with the measured medium, making them suitable for a range of applications.

Disadvantages:

- Sensitivity to Material Properties: The measurement can be affected by changes in the dielectric constant or conductivity of the material being measured.

- Environmental Sensitivity: Factors such as humidity, temperature, and changes in material properties can influence the accuracy of capacitive readings.

Applications:

- Measuring liquid levels, especially in transparent or low-dielectric liquids

- Level monitoring in silos containing powders and granular materials

- Environments with dust or powders, where non-contact measurement is needed

4. How to Choose the Right Level Measurement Technology

Selecting the appropriate level measurement technology depends on various factors, including the characteristics of the material being measured, the environmental conditions, and the specific requirements of the application. Here are some key considerations:

1. Material Properties:

Each level measurement technology is sensitive to different material characteristics. For example:

- Radar is ideal for measuring high-temperature, high-pressure, or corrosive materials, as it is less affected by the material’s properties.

- Ultrasonic is suitable for liquid and solid materials in stable environments, where temperature and pressure variations are minimal.

- Capacitive is best for liquids and granular materials with stable dielectric properties.

2. Environmental Factors:

Environmental conditions such as steam, dust, temperature, and humidity can influence sensor performance:

- Radar is highly resistant to environmental interference, making it suitable for challenging environments.

- Ultrasonic can be affected by steam, dust, and other atmospheric conditions, which may lead to inaccuracies.

- Capacitive sensors may also suffer from environmental factors like humidity and temperature fluctuations.

3. Accuracy Requirements:

If precision is crucial, radar typically provides the highest accuracy. Ultrasonic and capacitive sensors are more affordable but may be less accurate, especially in difficult environments.

4. Cost and Maintenance:

Ultrasonic and capacitive sensors generally have lower initial costs and require less maintenance, making them attractive for budget-conscious applications. However, radar sensors, while more expensive, offer superior performance and durability in harsh conditions.

Conclusion

Radar, ultrasonic, and capacitive level measurement technologies each offer unique advantages and limitations. The choice of the most suitable technology should be based on factors such as the material being measured, environmental conditions, required accuracy, and budget. By understanding the strengths and weaknesses of each technology, users can make informed decisions that enhance operational efficiency, reduce costs, and improve safety in their processes.