Level measurement may seem basic in process control, but its reliability directly impacts safety, efficiency, and production continuity.

Across industries—especially chemical and petrochemical—engineering teams are increasingly replacing ultrasonic level transmitters with radar technology.

Why is this shift happening? The answer lies in physics, performance, and field experience.

1. How They Detect Level: Radar vs. Ultrasonic

Radar Level Transmitters

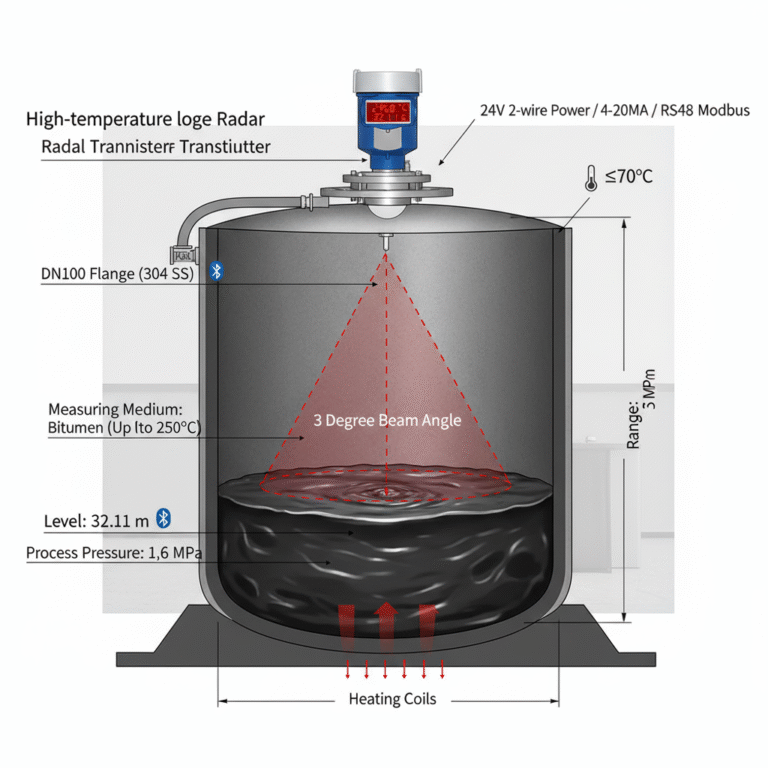

Radar instruments emit microwave or millimeter-wave electromagnetic pulses toward the medium.

The signal reflects from the product surface and returns to the antenna.

By measuring time of flight, the system calculates the height of the material.

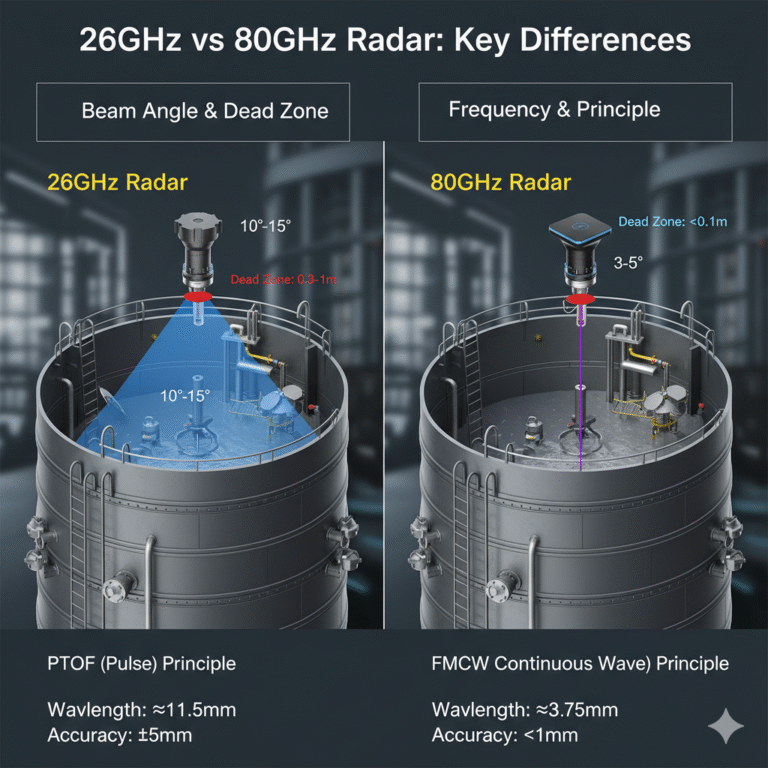

Typical operating frequencies: 6–80 GHz

Minimal influence from temperature, pressure, vapor or humidity

High-frequency radar provides sharper separation of echoes and better performance in challenging conditions

This makes radar highly tolerant of

✔ steam,

✔ dust clouds,

✔ agitation,

✔ and closed vessels.

Ultrasonic Level Transmitters

Ultrasonic transmitters operate using acoustic waves, typically in the 20–200 kHz range.

Echo time is converted into level, similar to radar.

Advantages:

Simple design

Lower hardware cost

Easy installation

However, acoustic waves are strongly influenced by environmental conditions, which limits reliability in industrial processes.

2. Performance Under Real Industrial Conditions

Industrial tanks are rarely “clean and quiet.”

Steam, turbulence, foam, temperature gradients, and pressure fluctuations are commonplace.

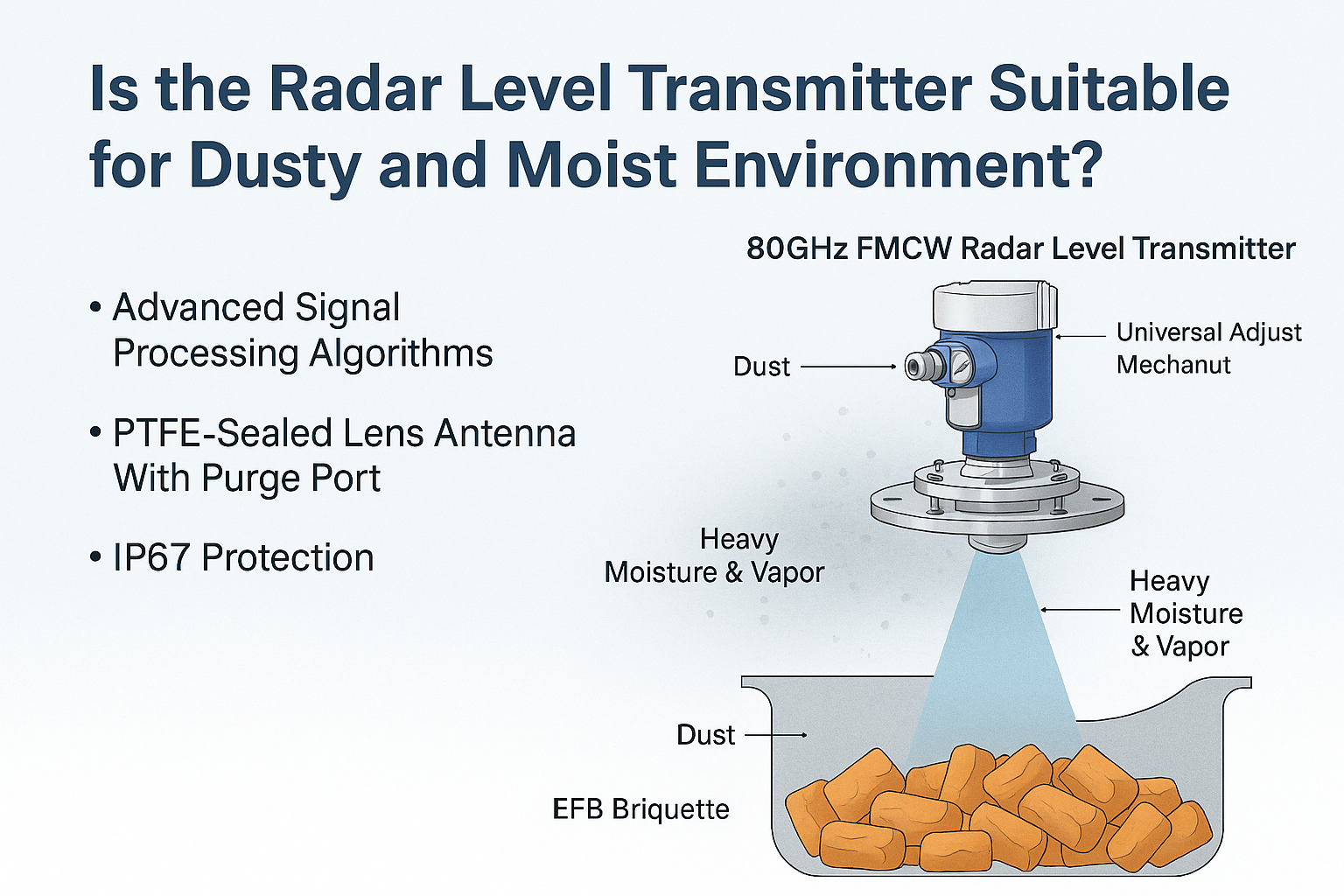

Radar in Harsh Environments

Radar inherently resists:

High temperature & high pressure

Foam and vapor layers

Heavy dust

Noise from mixers and falling product

Because electromagnetic signals are mostly unaffected by gas-phase properties, radar maintains stable echoes even when conditions change rapidly.

Ultrasonic Limitations

Acoustic waves do not travel as consistently:

Temperature shifts → change speed of sound → create errors

Vapor and foam → absorb or scatter sound

Dust → weakens echo signal

Pressure variations → distort measurement path

Result: ultrasonic readings may fluctuate or drop out entirely in demanding service.

3. Accuracy and Measuring Range

Radar

Modern radar level sensors achieve:

Accuracy to ±1 mm

Measuring ranges up to 100–150 meters

Suitable for tall vessels, silos, or bulk solids storage

Ultrasonic

Typical range < 15 meters

Works well in open tanks or water treatment systems

Performance declines sharply with disturbances

4. Cost Is More Than the Purchase Price

Ultrasonic – Lower Initial Cost

Ultrasonic instruments are attractive for basic applications due to:

Minimal upfront investment

Rapid commissioning

But maintenance grows over time:

Parameter drift

False readings

Higher service frequency when process conditions change

Radar – Lower Lifecycle Cost

Radar hardware pricing has fallen significantly as technology matured.

When combined with lower maintenance demand, radar often delivers:

Better uptime

Less engineering supervision

Fewer technician interventions

Higher long-term cost efficiency

5. Digitalization: Radar Becomes a Smart Measurement Node

New-generation radar instruments go beyond measurement.

Advanced capabilities include:

Bluetooth commissioning via mobile app

Local wireless setup without opening housings

Cloud monitoring and remote diagnostics

OTA (over-the-air) firmware upgrades

Adaptive echo learning algorithms

These features:

Reduce on-site workload

Improve troubleshooting accuracy

Enable remote support

Support predictive maintenance

Extend instrument lifetime without shutdown

For many chemical plants, this digital transformation is the deciding factor.

6. Practical Selection Guide

| Condition | Recommended Technology |

|---|---|

| Steam, foam, dust, agitation | Radar |

| Tall silo or enclosed tank | Radar |

| High accuracy requirement | Radar |

| Open water basin / wastewater | Ultrasonic |

| Strict budget, clean conditions | Ultrasonic |

Conclusion

Ultrasonic and radar level transmitters both have a place in industry.

However, as process conditions become more complex—and operational reliability becomes more critical—radar delivers superior stability, accuracy, and lifecycle value.

For:

Chemical processing,

Petrochemicals,

Mining,

Bulk solids,

High-temperature or vapor-heavy vessels,

Radar has become the preferred choice, not because ultrasonic is outdated, but because radar performs where conditions demand more.