Radio frequency impedance (RFI) technology is a new type of level measurement that has developed from capacitive technology. It is more reliable, accurate, and versatile, addressing the limitations of traditional capacitive level sensing. RFI technology is considered an upgrade to capacitive level measurement.

What is Radio Frequency Impedance (RFI)?

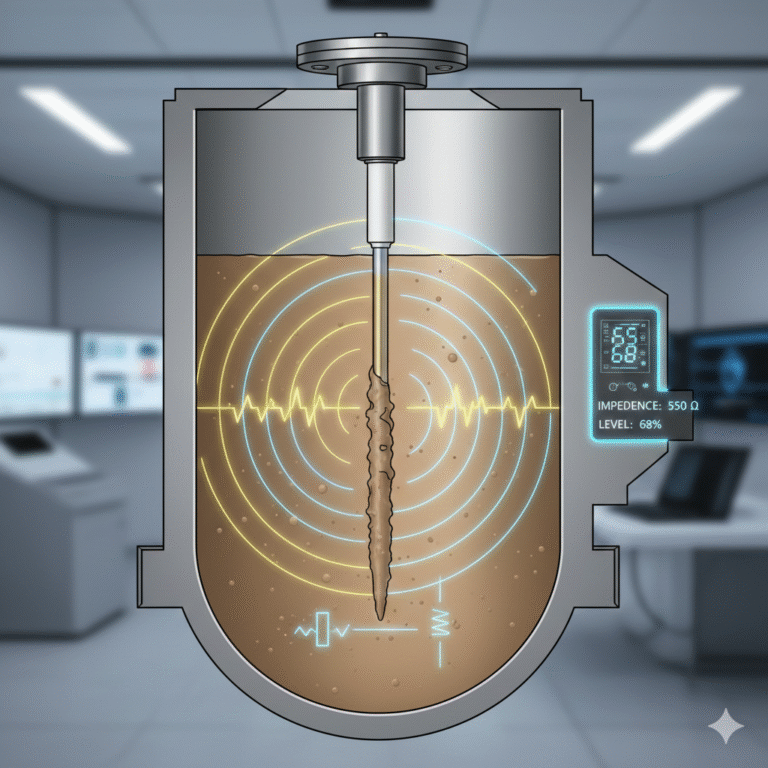

Impedance refers to the reciprocal of electrical resistance and is a combination of resistance, capacitance, and inductance components. Radio frequency refers to high-frequency electromagnetic waves. Therefore, radio frequency impedance is a technology that uses high-frequency radio waves to measure the impedance (or admittance) of a material.

During operation, the sensor of the instrument forms an impedance value with the container wall and the measured medium. As the level changes, the impedance value changes accordingly. The circuit unit then converts this impedance value into a level signal output, enabling accurate level measurement.

Technical Improvements Over Capacitive Technology

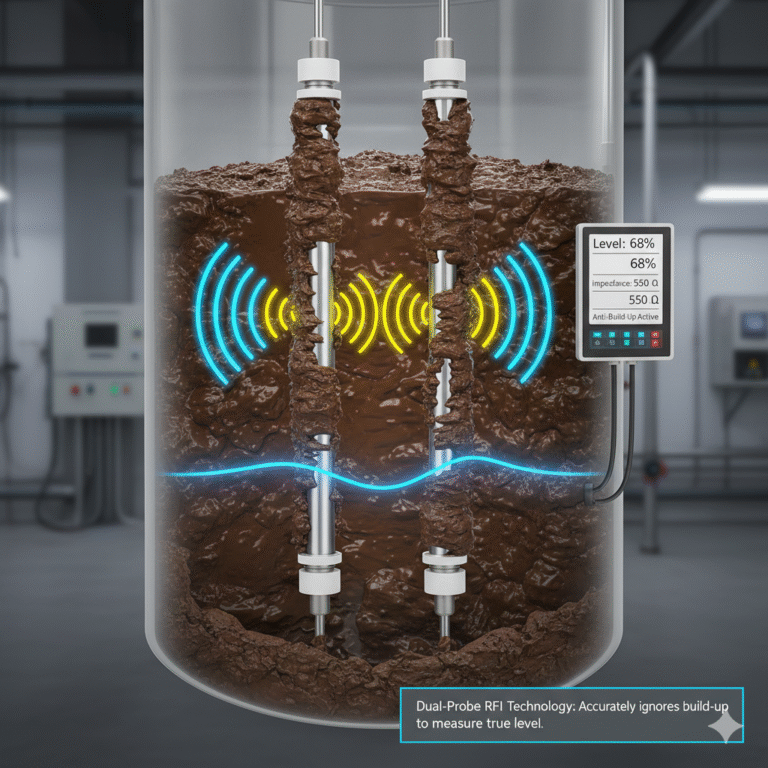

In addition to the improvements mentioned above, RFI technology also incorporates two key electrical circuits, a result of the significant findings in dealing with conductive material build-up. These innovations are critical for ensuring the reliability of measurements, even in challenging conditions.

The two additional circuits are the oscillator buffer and the AC modulation chopper driver.

Oscillator Buffer: In containers with highly conductive media, the contact point may act as a pure capacitor, and when material builds up on the sensor, it becomes a complex impedance due to the resistive properties of the build-up. The oscillator buffer ensures the energy consumed by the impedance does not drop the oscillator voltage, avoiding measurement errors.

AC Modulation Driver: For conductive media, the sensor’s insulating layer’s contact point extends the effective capacitance measurement to the top of the material build-up, causing measurement errors. The AC modulation driver circuit helps differentiate between the capacitance and resistance of the build-up, eliminating these errors.

With these technical enhancements, RFI technology has proven to be highly effective in real-world applications.

Advantages

Excellent Anti-Hanging Material Ability

A core advantage of RFI technology. Traditional capacitive level meters suffer from build-up of sticky materials like asphalt, paint, or wet cement on the probe, which can lead to inaccurate readings. RFI technology uses a dual-probe or coaxial probe structure along with specialized electronics to compensate for the admittance changes caused by material build-up, accurately ignoring the build-up and measuring the true level.

Wide Application Range

Medium Type: RFI technology works well for liquids, solids, powders, and even corrosive or high-temperature media.

Dielectric Constant: It has a low requirement for the dielectric constant (insulating properties) of the material. It can even measure materials with low dielectric constants, like plastic pellets or dry sand, making it more versatile than some other instruments.

Good Stability and High Reliability

Due to its strong anti-interference and anti-hanging material design, RFI level meters have excellent long-term operational stability in complex environments, with minimal maintenance. The electronic components are typically industrial or military-grade, ensuring durability in harsh environments.

Flexible Installation

RFI level meters offer multiple probe types, such as rod, cable, or coaxial probes, suitable for various container shapes and installation requirements. They also support top or side mounting.

High Degree of Intelligence

Modern RFI level meters often feature self-diagnostics, on-site calibration, parameter settings, and communication protocols like HART or PROFIBUS, making them ideal for integration into automated control systems for remote monitoring and management.

Disadvantages

Relatively High Price

Compared to traditional level meters like float or static pressure types, RFI meters have more complex technology and higher manufacturing costs, making them more expensive to purchase initially.

High Installation Requirements

To ensure measurement accuracy, the probe must maintain sufficient distance from the container wall to avoid errors caused by wall effects. If the container has internal structures like agitators or heating pipes, careful installation is required to avoid physical collisions or interference, which can lead to inaccurate readings.

Potential Electromagnetic Interference

Although RFI instruments are designed to be resistant to interference, strong electromagnetic fields from sources like large motors, frequency converters, or other high-power equipment nearby can still disrupt the high-frequency signals and affect measurement stability.

Challenges in Extreme Conditions

Long Measuring Range: For very tall tanks (tens to hundreds of meters), cable probes may experience signal attenuation and swinging issues. In such cases, radar-based level meters might be a better choice.

Turbulent Surfaces: If the material’s surface is highly turbulent (e.g., liquids under strong agitation), although damping time can be adjusted to smooth out readings, real-time measurement may still be impacted.

Probe Susceptible to Physical Damage

Probes, particularly rod or cable types, are exposed inside the container. If the material drops with high impact or if there are moving components inside the container, the probe may be damaged or bent.

Conclusion

Radio frequency impedance level meters are advanced, reliable instruments, particularly suited for measuring complex materials that tend to adhere to surfaces, are corrosive, or have varying dielectric constants. If your application involves these types of materials and the budget allows, RFI level meters are an excellent choice. However, for simple, clean liquid level measurement with a lower budget, more economical options may be better suited.