In this article, we will discuss the fundamental principles of passive input modules in Digital Input (DI) systems, specifically for Distributed Control Systems (DCS). The content will cover detailed explanations of the hardware, working process, connection methods, advantages, and common issues encountered in practical applications.

1. Core Definitions and Fundamental Differences

A Passive Input (often referred to as dry contact) means that the input module does not provide a power source to the field equipment. It simply detects whether a switch or contact from the external device is open or closed, acting as a signal receiver without supplying power to the circuit.

To better understand this, it is important to compare it with Active Input:

Passive Input:

Power Source: Provided by the field device or an external independent power source.

Module Role: Purely a detector or receiver.

Signal Flow: Field power → Field switch → DI module input → Common ground → Field negative.

Metaphor: Like using a flashlight without a battery to check if an electrical outlet has power. The flashlight itself doesn’t generate power, it only indicates whether power is present when it lights up.

Active Input:

Power Source: Provided internally by the DI module (e.g., 24V DC).

Module Role: Both a power provider and detector.

Signal Flow: Module power → Output to common → Field switch → DI module input → Internal detection circuit → Module internal power negative.

Metaphor: Like using a flashlight with its own battery. When you press the switch (close the circuit), the flashlight lights up, powered by the module itself.

Core Difference: The key difference lies in the source of the power supply, which affects the wiring, noise immunity, and the specific applications of the input modules.

2. Hardware Composition and Circuit Analysis

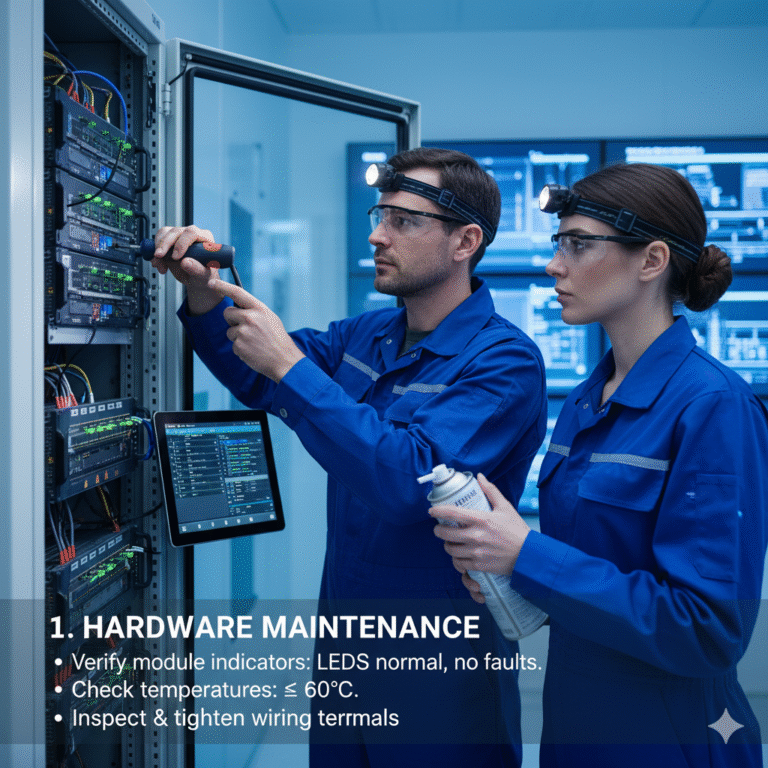

A typical passive DI module input channel consists of several critical components, each playing a vital role in ensuring reliable operation:

Input Terminal: The physical interface for connecting the signal wire from the field equipment.

Surge/Over-voltage Protection Circuit: Uses components like varistors or transient voltage suppressors (TVS) to protect the internal circuitry from high-voltage surges caused by lightning, electrostatic discharge, or other factors.

Current Limiting Resistor: A precision resistor designed to prevent excessive current and ensure the proper operation of components like optocouplers.

Optocoupler: The heart of the circuit, it converts the external electrical signal into light signals and then back into electrical signals, providing crucial electrical isolation between the field side and the system side. This ensures noise immunity and safety.

Output Buffer & Schmitt Trigger: The Schmitt trigger provides hysteresis to suppress noise and signal bouncing, ensuring clean, stable digital logic levels for the CPU.

CPU Interface: The final processed signal is sent to the DCS CPU for reading and processing.

3. Working Process

Let’s walk through the working process using a simple example: a field switch being closed to trigger the DI point to “ON”:

Initial State: The switch is open, no current flows into the DI module input terminal. The optocoupler’s LED is off, and the phototransistor is off. The Schmitt trigger detects low voltage, sending a “0” to the CPU, indicating “OFF.”

Field Action: The operator presses the button, closing the switch.

Signal Flow: The circuit is completed. Current flows through the optocoupler LED, causing it to emit light, which activates the phototransistor, changing the voltage detected by the Schmitt trigger.

Signal Conversion and Isolation: The signal is electrically isolated by the optocoupler and converted into a stable digital logic signal.

System Recognition: The DCS CPU reads the “1” (ON), triggering the appropriate control action, such as starting a pump or lighting an indicator.

4. Electrical Connection Methods

Passive DI modules are highly flexible, supporting various connection methods, such as:

Two-wire Switches (e.g., standard pushbuttons, limit switches):

Wiring: Field power + → Switch → DI module terminal; Switch → Common terminal → Field power -.

Three-wire Sensors (e.g., NPN or PNP proximity switches):

NPN (Open collector output): Output connects to the negative terminal when detecting an object.

PNP (Open collector output): Output connects to the positive terminal when detecting an object.

Four-wire Sensors: Typically have independent power and signal outputs (like a dry contact), making wiring similar to a two-wire switch.

5. Advantages and Disadvantages

Advantages:

High Flexibility: Can adapt to various field voltage levels (e.g., 24V DC, 120V AC, 220V AC).

Good Compatibility: Easily connects to NPN, PNP, and dry contact signals.

Electrical Isolation: Effective isolation between the field side and system side, reducing ground loop interference.

Easy Fault Diagnosis: Simple to troubleshoot by measuring voltage at the module terminals.

Disadvantages:

Complex Wiring: Requires additional power lines for each DI point, increasing cable costs and installation complexity.

External Power Required: Adds cost and maintenance for external power sources.

Higher Power Consumption: All DI points draw current from the external power source, leading to higher overall power consumption.

Potential Single Point of Failure: If multiple DI points share a single power source, failure of that source can impact all points.

6. Design Considerations and Common Issues

Design Considerations:

Safety and Isolation: Ensuring maximum isolation between the field and system side is critical to protecting the DCS.

Universal Compatibility: Offering a flexible “detection platform” for various field devices enhances the system’s versatility.

Cost Sharing: By shifting the power supply burden to the field side, the module design can be simplified and made more cost-effective.

Common Issues & Solutions:

Signal Jitter: Often caused by mechanical switch bounce.

Solution: Use hardware debounce (Schmitt trigger) and software filtering in the DCS configuration.

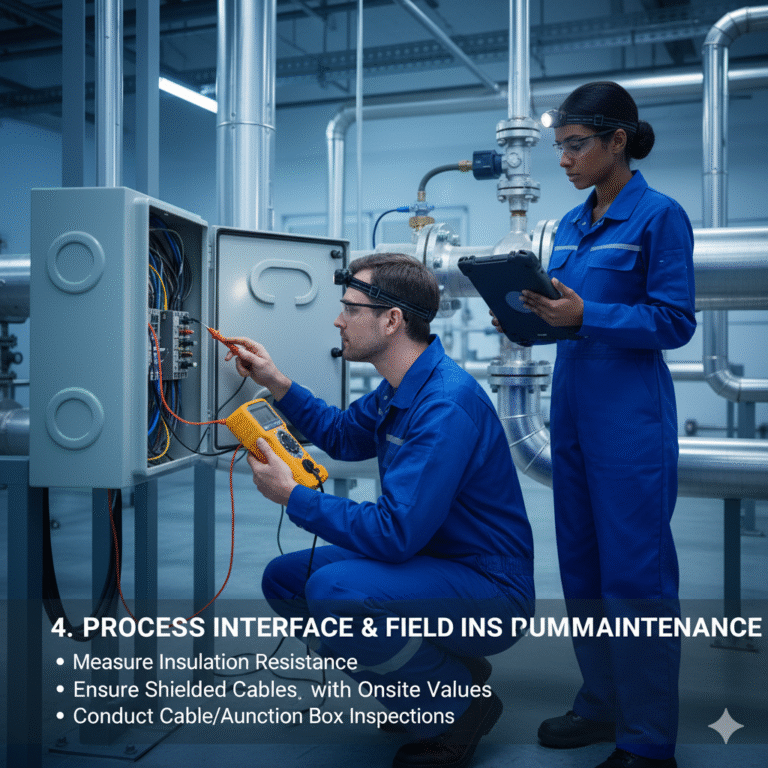

Electromagnetic Interference (EMI): Can cause erroneous signals even when the switch is idle.

Solution: Use shielded cables, filter software settings, and ensure proper grounding of the cables.

Incorrect Common Terminal Wiring: If the common terminal is not connected to the correct voltage (positive for PNP, negative for NPN), the module will not function properly.

Solution: Double-check wiring according to the sensor’s specification.

Conclusion

The passive input principle in DCS DI modules is a sophisticated design that integrates electrical isolation, signal conversion, and noise suppression. Although it may be more complex in terms of wiring and external power requirements compared to active inputs, its flexibility, compatibility, and reliability make it one of the most widely used input methods in industrial automation.