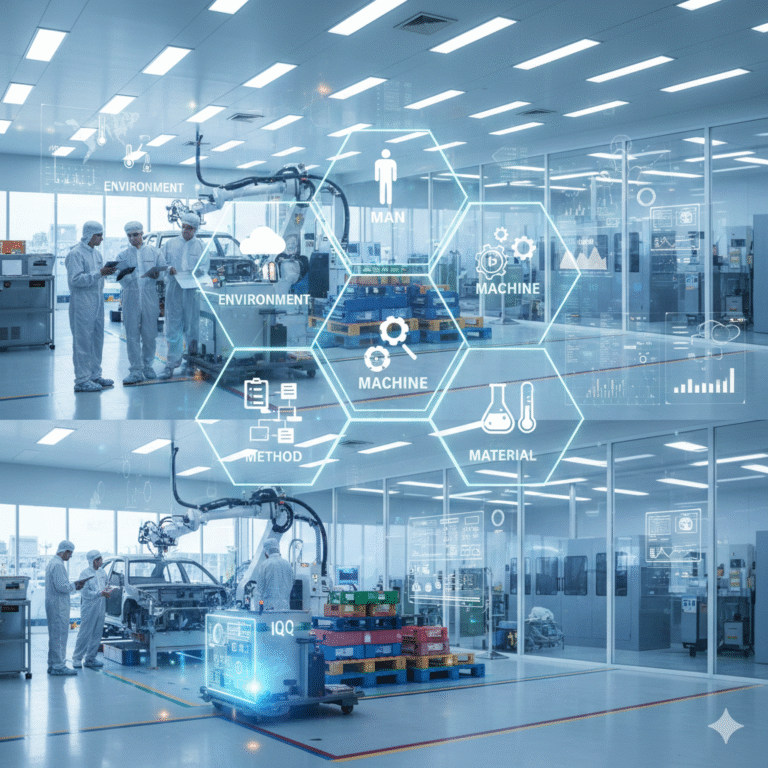

In the manufacturing industry, there exists a cross-industry analysis framework—Man (Human), Machine, Material, Method, and Environment—which serves not only as an essential quality management concept but also as a systematic approach for identifying issues, improving efficiency, and ensuring stable production. The five elements are dynamic, not static; they represent five dimensions of production activities, with any abnormality arising from deviations in one or more variables.

For frontline engineers, transitioning from an experience-based approach to a systematic one often means being able to identify problems more quickly, make more accurate judgments, and maintain a more stable production line rhythm.

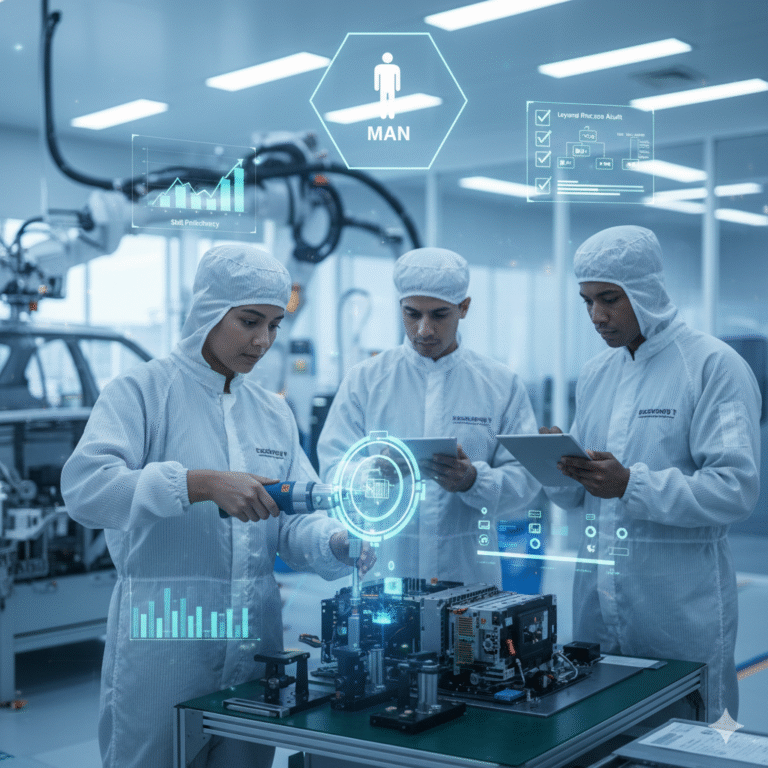

1. Man (Human)

1.1 Sources of Personnel Variation

In manufacturing systems, “human” is the most variable element but also the most trainable and moldable. It refers to the capabilities, consistency in operations, workload, behavior habits, and quality awareness of personnel involved in on-site operations, inspections, and process execution.

Personnel variation largely stems from skill proficiency, workload, and on-site behavior mechanisms. The ability of personnel directly affects action accuracy, rhythm stability, anomaly identification, and quality awareness; behavioral consistency determines process repeatability and process capability.

1.2 How to Enhance Personnel Consistency

Standard Operating Procedures (SOPs) and Key Action Definitions: Use action breakdowns, visual instructions, and training videos to make key actions (such as alignment during assembly, welding posture, inspection steps) visible and trainable.

Layered Process Audits (LPA): Regular checks by management and technical staff to ensure key actions are consistently followed, such as tool usage, fixture positioning, and inspection confirmation procedures.

Workload Optimization: Utilize action analysis tools to assess operational risks, reduce unnecessary movements and attention shifts, and improve operational stability.

Error-proofing Mechanisms: Implement structural positioning, quantity sensing, and tool binding to prevent errors at the system level rather than relying on individual memory or attention.

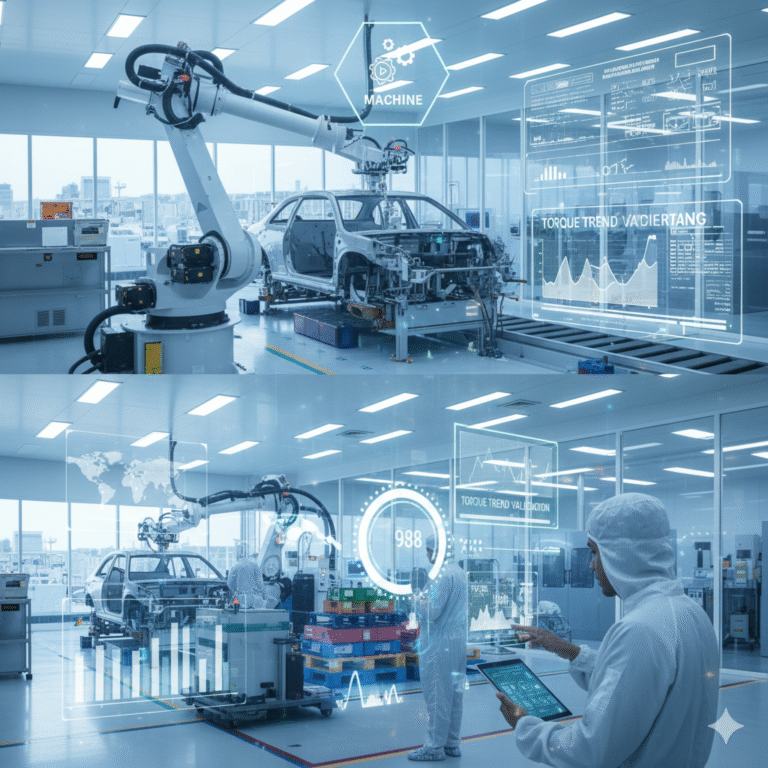

2. Machine

This refers to all equipment used for processing, assembly, inspection, and transportation, including their capacity limits, performance stability, maintenance status, and precision retention capabilities. Machines form the physical foundation of process stability, but their performance changes dynamically over time and requires systematic management.

2.1 The Essence of Equipment Status: Capability Range

Machines wear out over time, experience performance drift, and lose repeatability. Many quality fluctuations arise not from outright failure but from gradual shifts in equipment performance, so the focus of equipment management should be on trend monitoring and capability validation.

Machines should not be viewed simply as “good or bad” but as dynamically operating within a defined capability range. Factors like wear, temperature changes, vibration, and power fluctuations can cause performance drift, reducing process stability.

2.2 How to Make Equipment Behavior Predictable

Key Parameter Monitoring Windows: Set optimal, acceptable, and risk zones for parameters such as temperature, pressure, torque, and vibration, so that deviations can be detected in the early warning phase.

Parameter Trend Recording: Regularly record and trend parameters like temperature, back pressure, operating current, and positional accuracy, as this approach can uncover potential issues better than single-point checks.

R2R Precision Validation Fixtures: Use quick verification tools to check machine accuracy, such as press force-displacement curves, tool compensation checks, and calibration of positioning points.

TPM and Optimized Inspection: Simplify inspection items and use visual inspection checklists to help operators detect early anomalies.

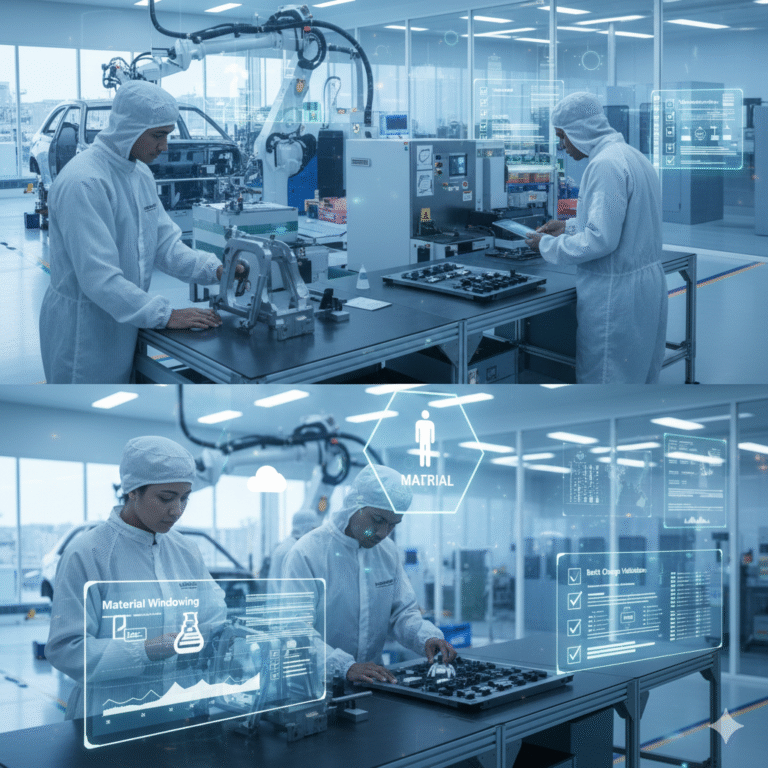

3. Material

Material refers to the components, raw materials, semi-finished products, and others entering the process, whose chemical, physical, and processing properties directly impact process performance. Material variation is a major source of manufacturing instability.

3.1 The Impact of Material Behavior on Process Stability

Materials are influenced by multiple factors such as supply, batch, transportation, and storage conditions. Even slight variations in material properties can lead to unstable assemblies, increased processing difficulty, or decreased welding reliability. Thus, material consistency is essential for process stability.

3.2 Turning Material from “Input” to “Controllable Variable”

Batch Change Validation: Execute size, appearance, fit, and performance validation when switching batches to confirm consistency and prevent differences from entering production.

Material Windowing: Establish usable ranges for key materials, such as flowability, hardness, thickness deviation, and surface cleanliness, to provide clear engineering parameters.

IQC Incoming Inspection + PQC Joint Verification: Control incoming material quality through inspections, while process verification confirms compatibility between materials and processes, ensuring stability.

Traceability: Record material batches for key processes, allowing traceability of any anomalies back to their source.

Storage Condition Control: Categorize and store moisture-sensitive, heat-sensitive, and easily contaminated materials, and maintain records and labels in accordance with operational guidelines.

4. Method

Method refers to process documentation, operation procedures, parameter settings, sequencing of steps, and inspection methods—it is the “operational logic” of the manufacturing system. The quality of the method determines whether the system can produce consistent outputs across different operators and conditions.

4.1 The Value of Process Documentation

Process documents should reflect the logical flow of the process, parameter guidelines, and operational details. However, if the documentation does not align with on-site practices, the issue often lies not in execution but in the process design’s failure to consider operational feasibility. Therefore, process methods must balance principles and practicality.

4.2 Engineering Implementation of Methods

On-site Verification: Before updating processes, engineers and operators should verify the feasibility of actions, suitable rhythm, and parameter attainability on-site.

Localized Control Plans: Clarify the frequency, method, and responsible personnel for each process control point.

Process Control Points: Set measurement checkpoints, action confirmation points, or energy monitoring points in each process to expose deviations before product failure.

Process Capability Analysis (CP, CPK): Assess process capability (e.g., using process capability indices) to determine if the process has sufficient margin, and adjust parameters or optimize equipment as needed.

Process Change Management (MOC/ECN): Evaluate and test changes to materials, equipment, parameters, or processes, ensuring that system stability is not affected, and provide training to personnel.

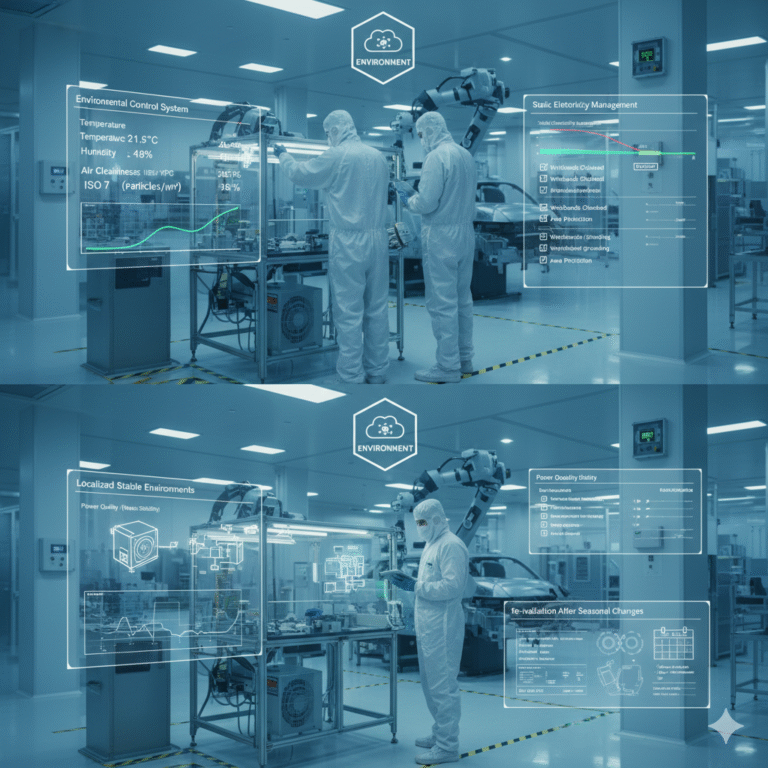

5. Environment

Environment refers to external factors such as temperature, humidity, air cleanliness, static electricity, power quality, vibration, and noise. It is one of the most subtle yet profoundly impactful elements in manufacturing systems.

5.1 The Impact of Environmental Factors on Processes

Environmental factors such as temperature, humidity, static electricity, cleanliness, and power stability can influence material and equipment behavior. For example, humidity can affect the size of moisture-sensitive materials and welding performance, while static electricity can damage sensitive components. Therefore, environmental conditions must be integrated into the process control system.

5.2 Engineering Control of Environmental Factors

Visualization and Automatic Alerts: Real-time display of temperature, humidity, or cleanliness data, with alerts or shutdowns triggered when limits are exceeded.

Static Electricity Management: Regular checks of wristbands, workbench grounding, and area protection to ensure sensitive processes are adequately protected.

Re-validation After Environmental Changes: After seasonal changes, regional upgrades, or equipment relocations, key process conditions should be re-validated.

Localized Stable Environments: Use localized air conditioning, hoods, or partitions to maintain stability in critical work areas, even when overall environmental conditions fluctuate.

6. The Interconnection of the Five Elements

When anomalies occur on-site, engineers should first identify “what has changed” and map the change to the five-element framework. By comparing normal and abnormal states, they can quickly narrow down the problem scope. Once the root cause is identified, corrective actions can be implemented, and system improvements can be solidified, continuously reducing future risks.

The five elements are not just analytical tools but also the underlying structure for understanding manufacturing system behavior.