During instrument installation, engineers often face environments unsuitable for safe equipment setup, such as explosive, flammable, cold, dusty, high-humidity, and regions with strong electrical or magnetic fields. In these environments, specific precautions must be taken to ensure safety and compliance.

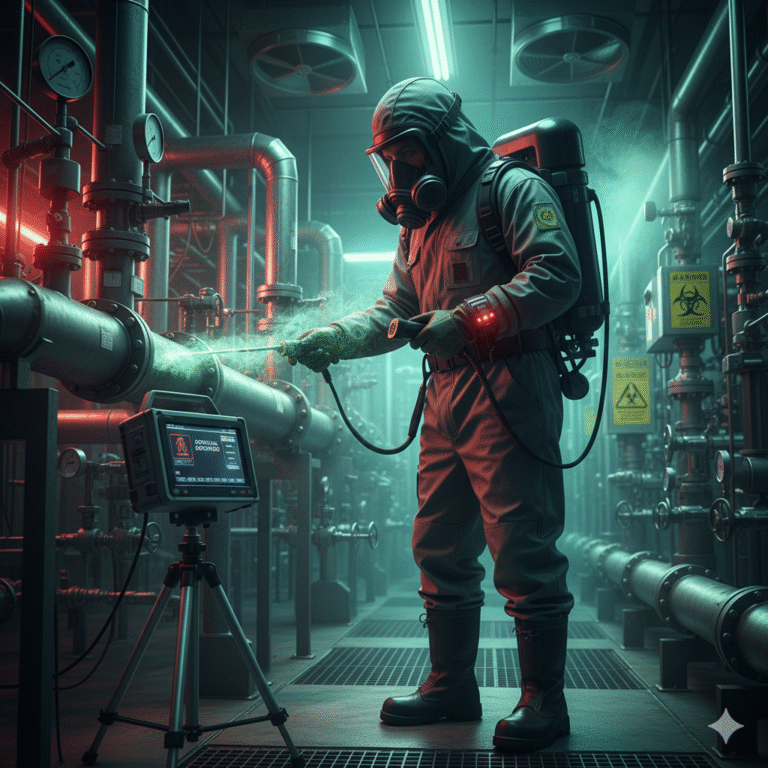

Installation in Toxic Environments

When installing instruments in environments with toxic media, careful attention to leak prevention in pipelines is essential. The risk of hazardous situations arises when toxic substances leak into the environment. Therefore, high standards are required for pressure transmission tubes, fittings, valves, pipeline construction, welding, and testing. This includes strength, tightness, and gas-tightness tests.

For new projects, health safety measures may not be necessary. However, for expansion or renovation projects, reliable safety protocols must be in place. Ventilation systems must be installed to ensure air circulation and remove toxic gases immediately in case of a leak, ensuring the safety of workers. Additionally, appropriate personal protective equipment (PPE), such as gas masks and protective clothing, should be available to handle any leakage.

In such environments, gas detection instruments and alarms must be used. Work can only proceed within the safe warning range; if it exceeds the warning level, work must cease immediately.

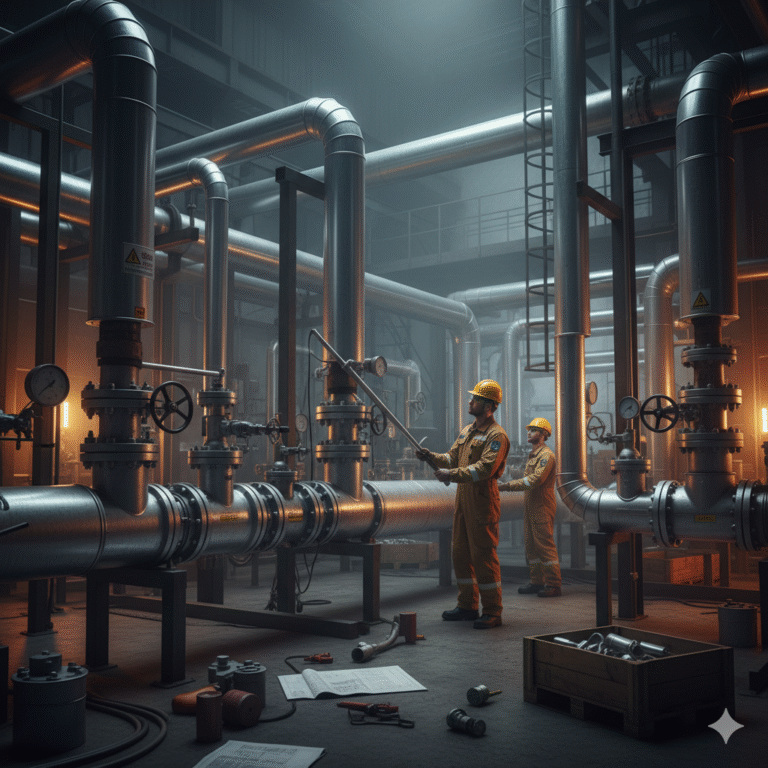

Installation in High-Temperature and High-Pressure Environments

High-temperature and high-pressure media are common in chemical production. Instrument pipelines, devices, and cables should be installed as far from high-temperature process equipment as possible to minimize temperature impacts. High-temperature pipelines and devices typically require insulation. Before installation, check the thickness of the insulation layer to ensure the first point of installation is outside of it. When selecting components like thermometer supports, longer options should be chosen (e.g., selecting supports of at least 140mm in length instead of 60mm).

For high-pressure systems, the following special requirements apply:

High-pressure pipes, fittings, and fasteners must undergo strict testing, in accordance with the “GBJ 235-82 Industrial Pipeline Construction and Acceptance Code” (for metallic pipelines).

High-pressure pipes should only be cold-bent once; repeated bending is not allowed.

When branching high-pressure pipelines, the use of tees is required. These must be inspected, and the material must match the pipeline.

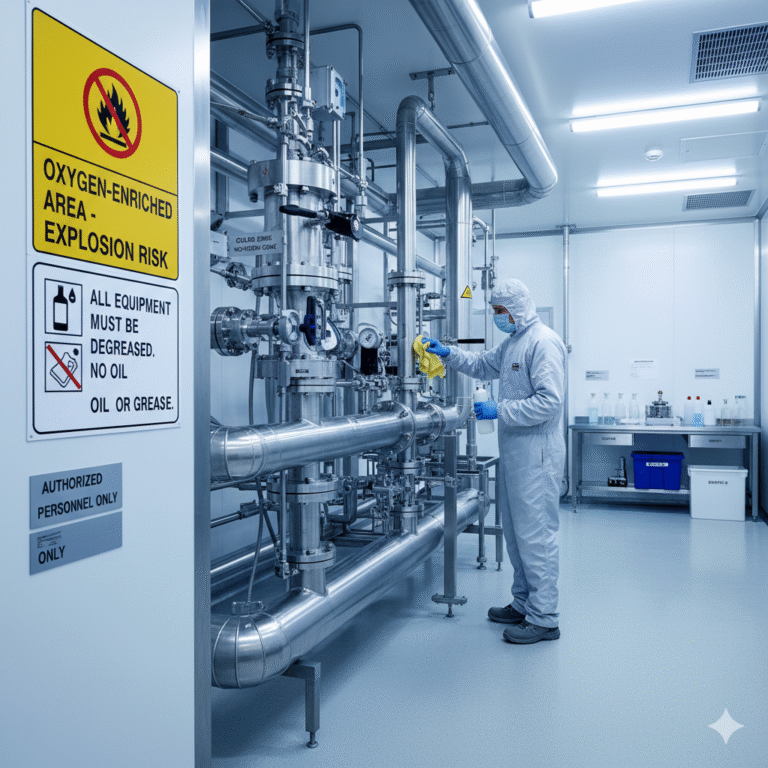

Installation in Oxygen-Enriched Environments

Oxygen supports combustion. If oil or grease is present on pipelines or equipment, it may ignite, potentially leading to explosions when exposed to open flames. Therefore, all instruments, valves, and equipment in oxygen-enriched environments must undergo degreasing treatment.

Common Degreasing Solvents:

Industrial Ethylene Dichloride: Suitable for degreasing metal components.

Carbon Tetrachloride: Suitable for ferrous metals, copper, and non-metallic components.

Trichloroethylene: Suitable for ferrous and non-ferrous metals.

Industrial Alcohol (≥95.6%): For general-purpose degreasing of instruments, valves, and pipes with lower requirements.

Concentrated Nitric Acid (98%): For degreasing equipment handling concentrated nitric acid.

Alkaline Degreasing Solution: For easily cleaned, simple-shaped parts and pipes.

It is critical that degreasing solvents are not mixed or exposed to strong acids or bases. When using solvents such as carbon tetrachloride, ethylene dichloride, or trichloroethylene, ensure components are completely dry, free of moisture. Degreased instruments, valves, and pipes must be sealed to prevent oil contamination after cleaning.

Degreasing Method:

Components with visible grease or rust should first be cleaned of contaminants before degreasing.

Easily removable instruments and valves should be disassembled and immersed in the degreasing solution for 1-2 hours.

For non-removable instruments, degreasing should be done by injecting the solvent, with a soaking time of at least 2 hours.

For degreasing pipes, use immersion for 1-1.5 hours or wipe with a clean cloth soaked in degreasing solvent until clean.

Inspection of Degreasing:

The degreased instrument should be inspected for cleanliness.

Direct inspection: No oil stains should appear when wiped with clean, dry white filter paper.

Indirect inspection: No ultraviolet light reflection or organic contamination should be detectable in tests using specific solvents.

After degreasing, components should be dried with clean, dry air or nitrogen, or by steam cleaning if allowed.