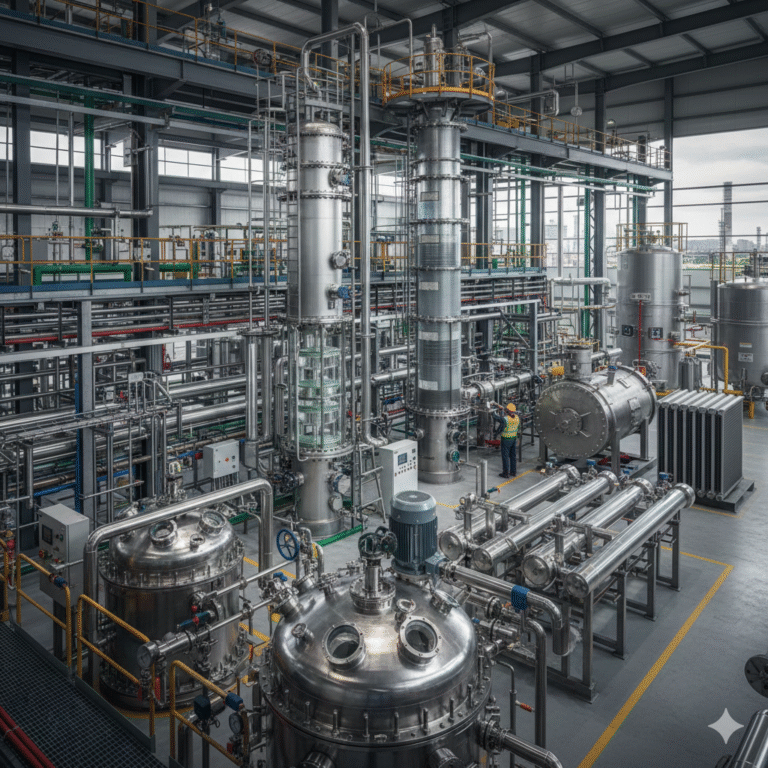

The stability, scalability, and long operational cycles of the chemical industry are not built on the process package alone. At its core, it relies on the chemical equipment system that can withstand high temperatures, high pressures, corrosion, erosion, multiphase flow, and complex reaction conditions over time.

Chemical equipment is more than just “hardware”—it is an integration of reaction engineering, thermodynamics, fluid mechanics, materials science, safety engineering, and control systems. The design, manufacturing, and operational quality of these systems directly determine the limits of a plant’s capabilities.

1. Reaction Equipment

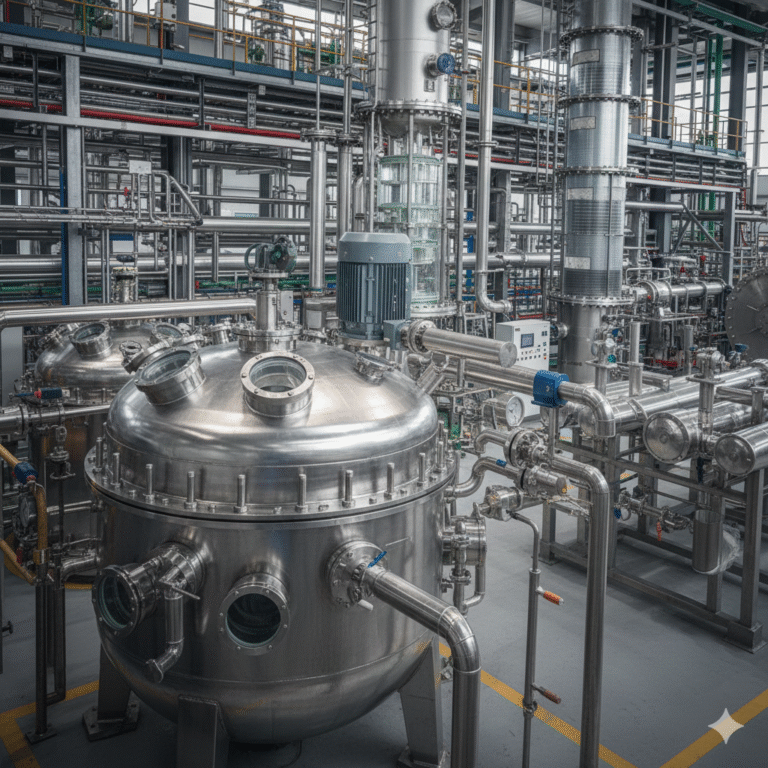

Batch Reactors

Widely used in batch or semi-continuous reaction processes, batch reactors are essential in fine chemicals, where they mix, react, heat, cool, disperse, or dissolve materials. The basic principle involves using a stirrer to generate a specific flow pattern, ensuring uniform contact of materials and maintaining heat and mass transfer. Heat is exchanged through jackets or internal coils to maintain an optimal reaction temperature.

Structure

A typical batch reactor consists of a vessel body, head, stirring shaft, blades, baffles, and jackets or internal coils. The type of blade used determines the flow field:

Propeller blades: Produce strong axial circulation and are suitable for low to medium viscosity systems and solid suspension scenarios.

Rushton blades: Generate strong radial flow, ideal for gas-liquid dispersion.

Anchor and frame blades: Used for high-viscosity materials, they primarily improve mixing near the wall.

Common Issues

Insufficient heat transfer, temperature control lag, local hotspots, and viscosity-induced heat exchange deterioration are common problems. Specifically:

Slow temperature rise is often linked to reduced heat transfer area, scaling in the heat exchanger, or insufficient heat exchange media.

Difficulty in cooling could result from peak exothermic reactions, uneven stirring, or thickened media.

A steady temperature display may not indicate a risk-free internal condition, especially during highly exothermic reactions where local hotspots might be masked.

Typical Failures

Stirring issues usually manifest as abnormal motor current, increased vibrations, or mechanical seal leakage. Poor mixing can cause changes in product color, higher impurity levels, and increased batch-to-batch variability. Heat exchange decay is reflected in prolonged heating or cooling times under the same operating conditions. Understanding the relationship between “stirring—heat transfer—physical property changes” helps in accurately diagnosing production anomalies.

Tubular and Fixed Bed Reactors

Used for continuous reactions, particularly those requiring precise residence time control, temperature gradient management, or reliance on catalysts, fixed bed reactors are commonly employed in catalytic processes.

Operating Principle

In tubular reactors, materials flow through narrow pipes, where heat control is achieved via heat exchange with the walls, operating close to plug flow. In fixed bed reactors, materials pass through a catalyst bed where reactions are catalyzed, and the reaction heat release and pressure drop along the bed length vary, requiring special attention to changes along the length of the bed.

Typical Phenomena

In real-world conditions, ideal plug flow is rarely achieved. Flow behavior often exhibits residence time distribution, wall effects, and radial temperature gradients. In fixed bed reactors, pressure drops gradually rise over time due to catalyst fouling or particulate accumulation, and temperature along the bed can become uneven, with local hotspots often forming near the inlet.

Common Operational Issues

For fixed bed reactors, a sudden increase in pressure drop usually indicates blockages or local coking at the inlet. Temperature shifts might be caused by gas-liquid distribution anomalies or localized catalyst aging. A decline in conversion rates is often due to catalyst deactivation or distributor issues. Long-term data trends in “temperature—pressure drop—flow rate” are more valuable than single-point measurements in troubleshooting.

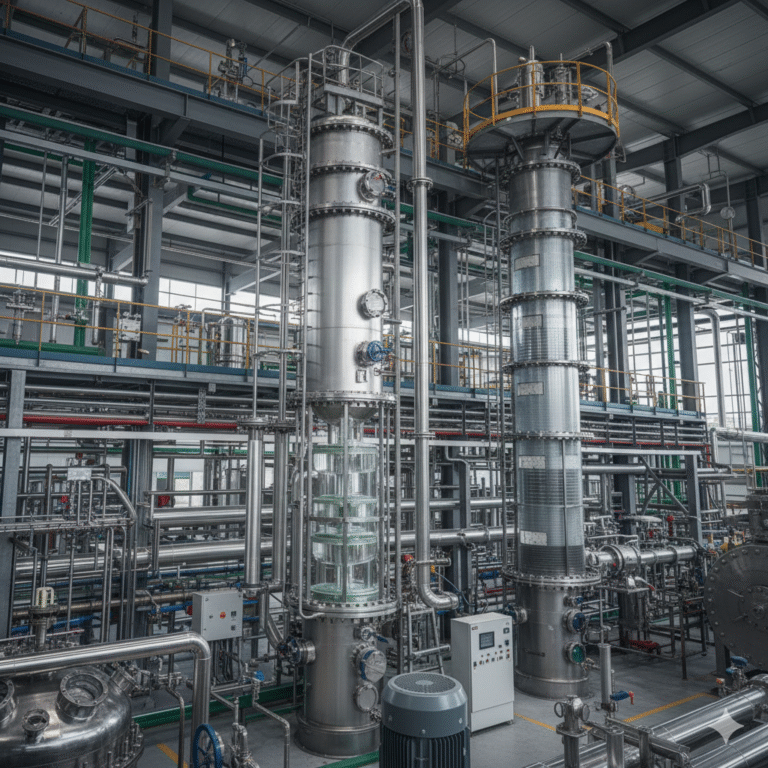

2. Column Equipment

Tray Columns

Tray columns are used for distillation, absorption, and desorption processes, where gas-liquid contact leads to component separation. The principle relies on gas rising through holes in trays, while liquid forms a layer and flows down through downcomers to the next tray. Separation efficiency depends on liquid layer height, gas velocity, and tray structure.

Tray Operating Regions

Low-load region: Liquid leakage occurs, and the liquid layer is hard to maintain, leading to low separation efficiency.

High-load region: Liquid flooding can happen, increasing pressure drop and even carrying over material.

Normal region: The liquid layer is stable, and gas-liquid contact is efficient.

Common Issues

Flooding, which causes a sudden rise in pressure and instability in the top temperature, leads to a drop in product quality. Leaking liquid, which results in continuous efficiency losses, might not cause significant pressure changes. Tray damage, such as downcomer blockages or deformations, will worsen distribution.

Structured Packing Columns

Structured packing is used for low-pressure drop separation operations, such as in distillation or extraction. It is sensitive to liquid distribution, which plays a critical role in efficiency. The liquid flows as a thin film on the packing, while gas flows upward for mass transfer.

Liquid Distribution Effects on Efficiency

Efficient distribution of the liquid results in a stable film of liquid on the packing, ensuring high mass transfer. Poor distribution leads to dry or wet spots, drastically reducing efficiency. Causes may include distributor blockages, uneven liquid flow, or packing settling. Monitoring changes in pressure drop and product quality sensitivity can indicate distributor issues.

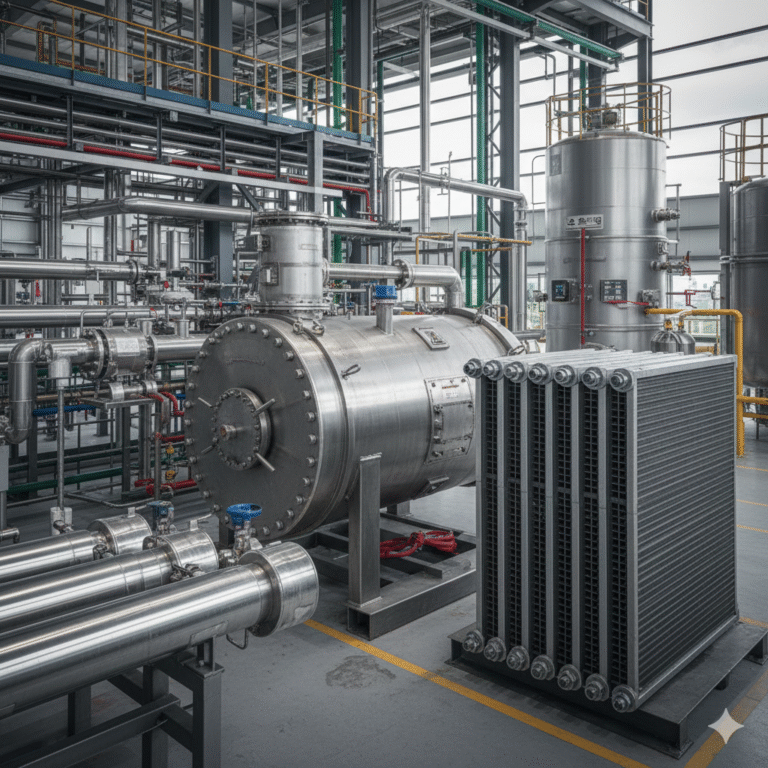

3. Heat Exchange Equipment

Shell-and-Tube Heat Exchanger

One of the most commonly used heat exchangers, the shell-and-tube type is applied in heating, cooling, condensation, and reboiling processes. It works by allowing hot and cold fluids to flow through separate channels (shell and tubes), with heat transferred through the tube walls.

Operation Issues

Heat transfer degradation is evident when the inlet-outlet temperature difference decreases, or the heating or cooling time increases. Pressure drops can gradually rise due to fouling, while sudden changes may indicate blockages or leaks. Cross-contamination between media is another concern, leading to performance degradation.

Plate Heat Exchanger

Used for high-efficiency heat exchange, especially in scenarios with low viscosity and high temperature differential requirements, plate heat exchangers use corrugated plates for heat transfer.

Typical Problems

Sealing issues, blockages from unprocessed particles, or cross-contamination due to leaks are common. Regular tightening of bolts, monitoring for contaminants, and frequent cleaning can help mitigate these issues.