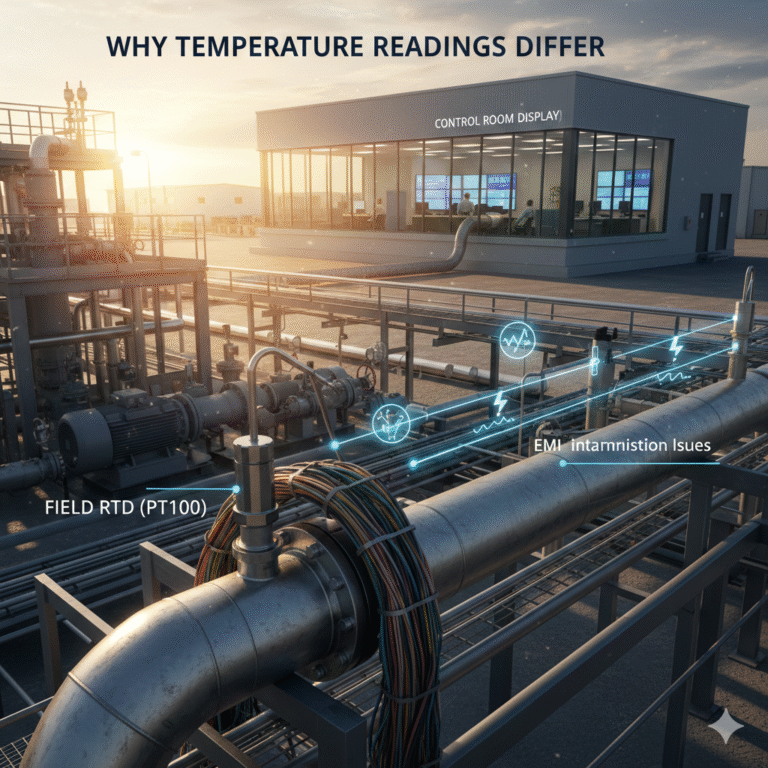

Resistance Temperature Detectors (RTDs), such as PT100 sensors, often show differences between the temperature measured at the field and the value displayed in the control room. These deviations are mainly caused by signal transmission losses, wiring conditions, environmental effects, and instrumentation accuracy. The detailed explanation is as follows.

1. Transmission-Related Errors (Primary Cause)

RTDs measure temperature based on resistance changes. When the signal is transmitted from the sensor to the control room, several factors can introduce additional resistance or noise, resulting in measurement deviation.

1.1 Lead Wire Resistance

Long cable runs introduce resistance into the measurement loop.

Two-wire RTDs: Lead wire resistance is added directly to the sensor value

→ results in higher temperature readings.Three-wire RTDs: If the three wires do not have identical resistance or if one wire has poor contact, the lead-wire compensation becomes inaccurate.

Four-wire RTDs: Provide the best compensation, but faults in any lead can still create error.

Example:

A 2 Ω total lead-wire resistance added to a PT100 equals approximately 5–6°C error.

1.2 Absence of Local Transmitter

If the RTD signal is transmitted directly as a resistance/voltage signal over long distance, the system is highly sensitive to:

voltage drop

cable resistance imbalance

electrical noise

Using a local 4–20 mA temperature transmitter eliminates most distance-related errors.

1.3 Electromagnetic Interference (EMI)

Signal cables routed near:

motors

VFDs

power cables

solenoids

UPS units

can pick up electromagnetic noise, causing fluctuating or shifted readings.

Proper shielding and grounding (single-end grounding) are essential.

1.4 Contact Resistance

Loose terminals, oxidized connectors, or poorly crimped lugs create unstable additional resistance, leading to intermittent or drifting values.

2. Device and Environmental Influences

2.1 Temperature Effects on Lead Wires

Lead wire resistance increases with ambient temperature.

A 10°C change can alter a long cable’s resistance enough to cause 1°C or more of temperature error in a PT100 loop.

2.2 Control Room Input Module Accuracy

The reading shown in the control room depends on:

ADC bit resolution

calibration accuracy

temperature drift of the input card

linearization errors

Lower-end modules may introduce ±0.3–0.5% error even when the RTD signal is perfect.

3. Sensor Installation-Related Errors

Sometimes the field reading itself is inaccurate due to installation conditions:

insufficient insertion depth

sensor not fully in contact with the media

measuring pipe wall temperature instead of process temperature

improper thermowell design

These errors may be misinterpreted as transmission issues.

4. Recommended Troubleshooting Procedure

Verify wiring type (3-wire or 4-wire recommended for industrial use).

Measure the lead-wire resistance and check whether wires are symmetrical.

Use a precision resistor box at the control room to validate the input module accuracy.

Temporarily install a local transmitter to compare 4–20 mA vs. raw RTD signal.

Check cable routing and ensure proper shielding and grounding.

Inspect terminals for oxidation or loose connections.

Validate field installation (insertion depth, thermowell contact, etc.).

5. Conclusion

Differences between field RTD measurements and control room readings are usually caused by:

lead-wire resistance

wiring imbalance

EMI interference

temperature drift

inaccurate input modules

or installation-related issues

Optimizing wiring (preferably 3-wire or 4-wire RTDs), adding local transmitters, improving shielding/grounding, and ensuring correct RTD installation can significantly improve measurement consistency and accuracy.