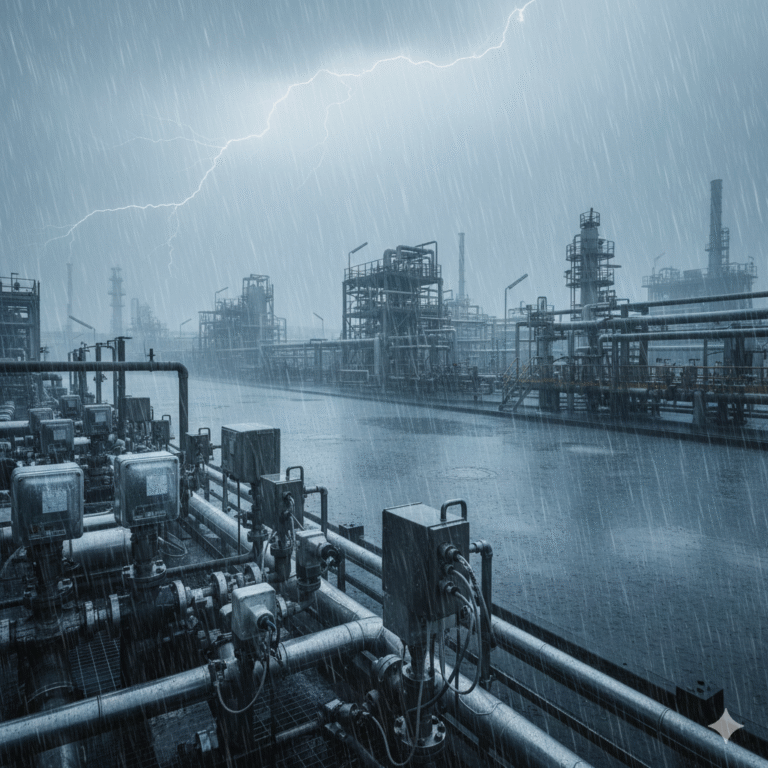

Industrial instrumentation in chemical plants is highly vulnerable during the rainy season due to moisture intrusion, condensation, lightning surges, corrosion, and cable insulation degradation.

This document provides a systematic and actionable protection strategy based on four principles:

Prevent Water Ingress • Prevent Moisture & Condensation • Prevent Lightning & Surge Damage • Prevent Corrosion & Short-Circuit Failures

The recommendations are organized across four dimensions:

environmental preparation, instrument protection, electrical safeguarding, and inspection & maintenance, forming a complete “proactive prevention + real-time monitoring + emergency response” system.

1. Environmental Preparation – Eliminating Water and Moisture at the Source

1.1 Outdoor Area Waterproofing (blocking rainwater pathways)

• Field instruments

Install curved stainless-steel rain shields (SUS304), with a downward tilt of ≥30° and overhang extending ≥10 cm beyond cable entries.

Mount instruments ≥1.5 m above ground to avoid splash zones and drainage channels.

Ensure surrounding areas have no standing water; any accumulated water must drain within 24 hours.

• Instrument cabinets / Junction boxes

Add splash-proof bottom plates (≥15 cm above ground).

Install rain drip edges + EPDM sealing strips (inspect every 3 months).

Drill two φ10 mm drainage holes at the cabinet bottom (with dust screens).

Use a rain-proof exhaust fan (≥0.3 m³/h) to maintain slight positive pressure.

• Cable trenches / Conduits

Maintain trench slope ≥2‰, install sump pits every 50 m with automatic submersible pumps.

Seal both ends of conduits using waterproof sealing compound + heat-shrink tubing; ensure pipe ends slope 5° downward.

Apply epoxy anti-corrosion coating to sidewalls (thickness ≥1.5 mm).

• Corrosive environments (acid/alkali workshops)

Add FRP rain hoods with internal anti-condensation insulation to prevent moisture dripping onto instruments.

1.2 Humidity Control – Preventing Condensation

• Control rooms / Instrument cabinets

Install dehumidifiers + humidity alarms; maintain humidity ≤60%.

Place silica gel packets inside cabinets (inspect every 15 days).

Air-conditioners should operate in “dehumidification mode” during rainy season.

• Outdoor integrated instruments

Prefer models with internal heaters (auto-start when T < 5°C or RH > 70%).

Heater power typically 5–10 W, depending on enclosure volume.

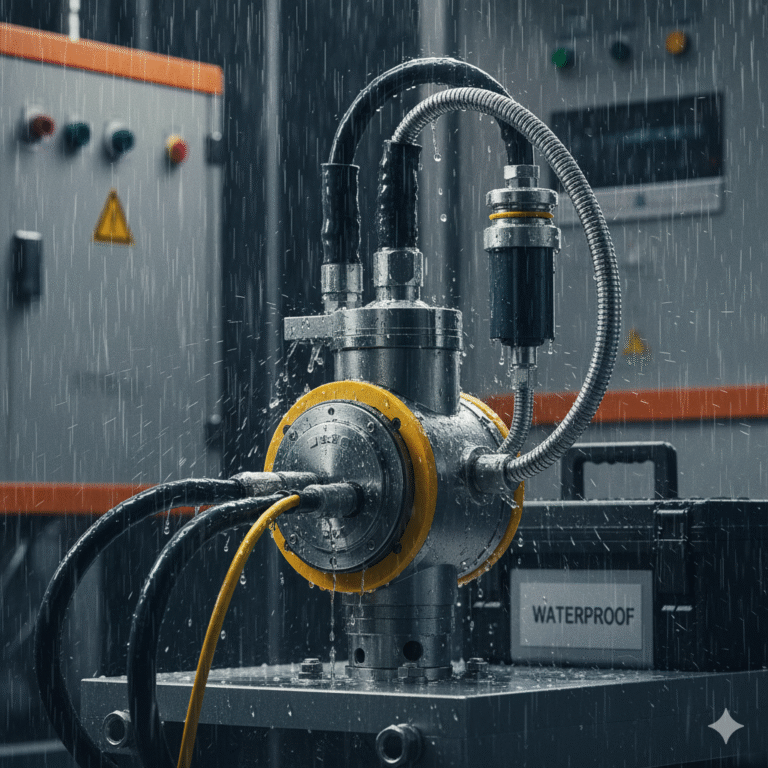

2. Instrument Protection – Reinforcing Sealing and Suitability

2.1 Sealing Measures – Eliminating Water Entry Points

• Housing sealing

Tighten all enclosure screws; replace missing washers.

Use PTFE gaskets (≥3 mm) at flange interfaces.

Cable entries: apply IP-rated cable glands, waterproof tape + heat-shrink tubing.

Never leave cable joints exposed; perform splicing only inside a waterproof junction box filled with sealing gel.

• Sensor protection

Use dual O-ring + compression cap for insertion probes (material: FKM/Viton).

Protect sensor cables using stainless-steel flexible conduit.

• Portable instruments

Store in waterproof toolboxes with silica gel; use protective bags outdoors; wipe dry after use.

2.2 Correct Instrument Selection – Prioritizing Anti-Rain / Anti-Moisture Models

• Protection ratings

Outdoor general use: IP65 or above

Frequent rain / temporary immersion: IP67

Coastal or corrosive environments: IP68 + Anti-corrosion coating (PTFE ≥2 mm)

• Special instruments

Thermocouples / RTDs

Use waterproof terminal heads (IP65) with internal desiccant.

Apply conformal coating (acrylic) to terminal blocks.

Pressure / Differential pressure / Level transmitters

Prefer welded diaphragm seals to avoid micro-leaks.

Ensure enclosures include a condensation drain port.

Mount transmitter head upward; diaphragm downward.

Analytical instruments (pH, DO, conductivity)

Use electrodes with waterproof vent valves.

Select shielded waterproof cables.

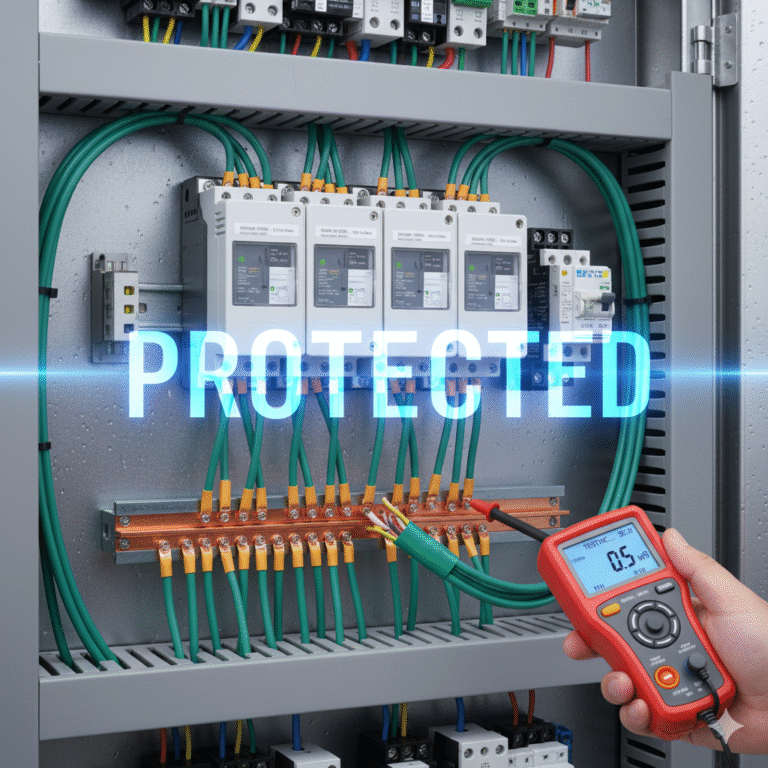

3. Electrical & Circuit Protection – Preventing Surge, Short-Circuit, and Insulation Failures

3.1 Lightning Surge Protection

• Install Surge Protective Devices (SPD) at key locations

Signal loops (4–20 mA, RS485)

Install signal-type SPD

Response time ≤25 ns

Ground resistance ≤4 Ω

Power supply lines (220 VAC / 24 VDC)

Use power-type SPD

Surge capacity ≥20 kA

Add spark gaps between neutral and ground

Outdoor instruments

Each instrument should have individual SPD protection (avoid sharing).

• Grounding system

Use single-point grounding for housings, shielding, SPDs

Ground grid resistance ≤4 Ω

Keep instrument grounding separate from power grounding (distance ≥5 m)

3.2 Cable & Insulation Protection

• Cable selection

Use armored waterproof cables (PE/PVC sheath, steel tape/wire armor).

Avoid standard rubber cables outdoors.

• Insulation resistance testing

Before rainy season, test insulation using 500 V megger:

Signal cables: ≥20 MΩ

Power cables: ≥10 MΩ

• Redundancy

Safety-critical loops should adopt dual redundancy + isolation,

isolation rating ≥2500 VAC.

4. Inspection & Maintenance – Dynamic Monitoring and Early Risk Elimination

4.1 Daily Inspection

Check housings, rain shields, junction boxes for water marks or damage.

Ensure cables are not soaking in water.

Monitor displays for drift or abnormal values.

Check cabinet humidity (≤60%) & temperature (15–30°C).

Verify cable glands, flanges, connectors are dry and tight.

Ensure drainage holes and exhaust fans operate properly.

4.2 Scheduled Maintenance

• Before rainy season

Replace aged sealing strips and gaskets.

Tighten all enclosure fasteners.

Test dehumidifiers, heaters, pumps, SPDs.

Flush cable trenches; reinforce anti-corrosion coating.

• During rainy season (weekly)

Additional insulation resistance checks.

Remove debris from rain shields.

Inspect grounding terminals for rust/looseness.

• After rainy season

Open junction boxes, perform low-temperature drying with heat gun.

Apply conformal coating if needed.

Recalibrate 4–20 mA loops (≤±0.5% FS error).

Replace damaged cables, corroded probes, or wet components.

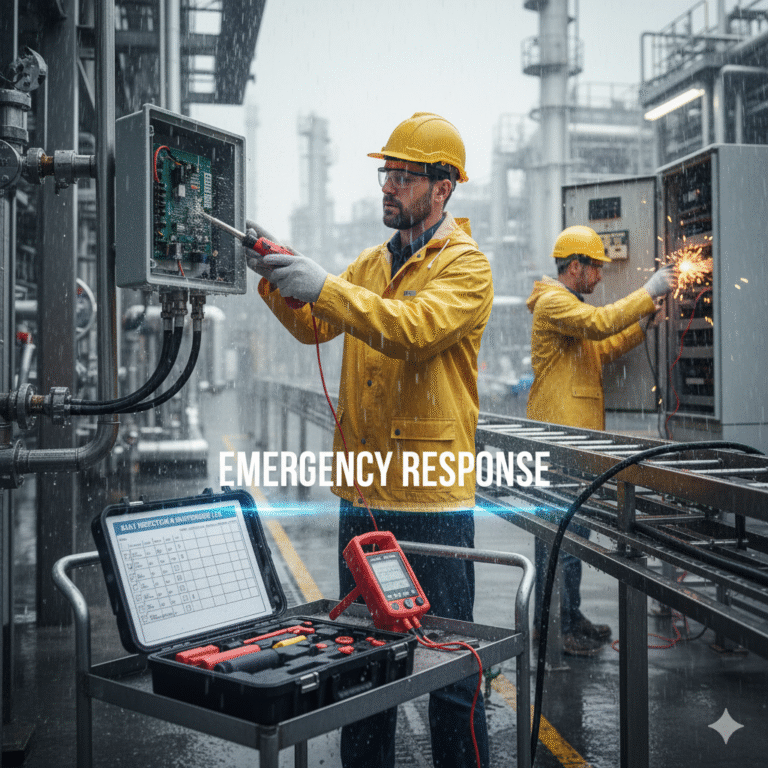

5. Emergency Handling Procedures

5.1 Water ingress / Short-circuit

Immediately cut power.

Disassemble terminals; blow with nitrogen (0.3 MPa, ≥5 minutes).

Dry thoroughly, perform insulation test → restore power only if qualified.

If PCB is burnt, replace instrument.

5.2 Surge damage

Check SPD status (indicator color, fuse).

Replace SPD and retest loop insulation.

Recalibrate or replace affected instruments.

5.3 Condensation-related signal drift

Activate internal heaters.

Run dehumidifier until humidity <60%.

Re-zero and re-range transmitter.

Increase inspection frequency.

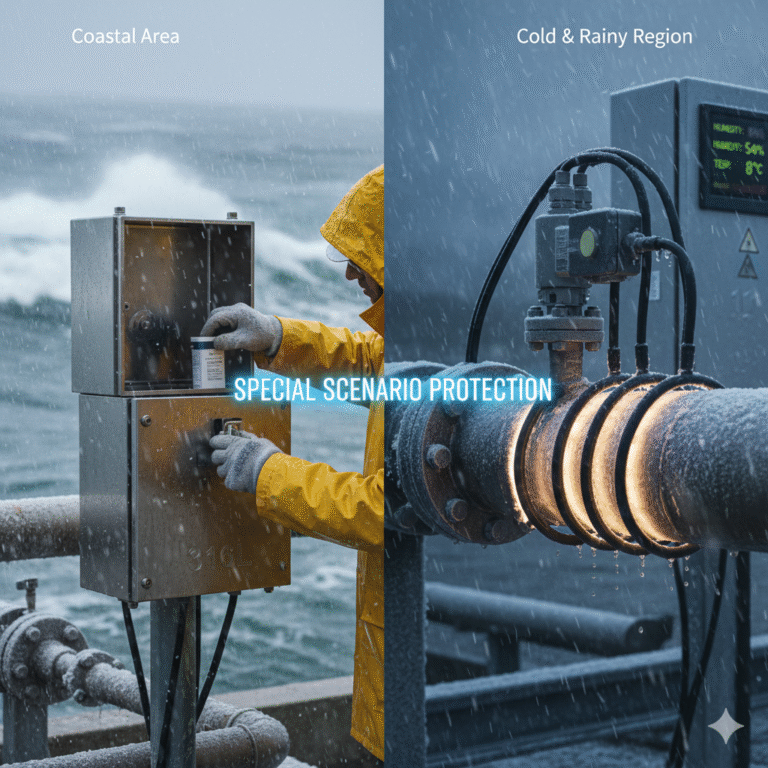

6. Special Scenario Protection

6.1 Coastal Areas (salt spray + heavy rainfall)

Use 316L housings with fluorocarbon coating (≥2 mm).

Install salt-filter cartridges in junction boxes (replace every 10 days).

Use IP67 anti-corrosion SPDs.

6.2 Cold & Rainy Regions (condensation + icing)

Install heat tracing on cable and sensor body (set to 5–10°C).

Keep cabinet heater running continuously.

Target humidity ≤55%.

6.3 Hazardous Areas (explosion-proof zones)

All rain shields, junction boxes must match Ex rating.

Install explosion-proof SPDs.

Use explosion-proof flexible conduits for grounding and wiring.

Conclusion

A robust rainy-season protection system for chemical plant instrumentation requires the integration of:

• Proper environmental design

• Reliable sealing & material selection

• Surge & electrical protection

• Dynamic inspections

• Timely emergency response

Implementing the above measures minimizes signal drift, short circuits, instrumentation failures, and prevents unplanned shutdowns—ensuring stable, safe, and continuous plant operation throughout the rainy season.