Core Principle:

Temperature-related faults in electrical or industrial systems can be quickly located using the inherent resistance–temperature characteristics of NTC/PTC thermistors and the mV output characteristics of thermocouples.

By performing three diagnostic steps—static resistance check, dynamic heating/cooling test, and loop continuity/voltage measurement—more than 90% of temperature-related failures can be accurately identified.

1. Identify the Sensor Type First (Avoid Misdiagnosis)

| Sensor Type | Key Characteristics | Typical 25°C Value | Failure Estimation Logic |

|---|---|---|---|

| NTC Thermistor (home appliances, automotive) | Negative temperature coefficient: Temp ↑ → Resistance ↓ | 1kΩ / 5kΩ / 10kΩ / 50kΩ (e.g., “103” = 10kΩ) | ±30% drift → inaccurate reading; OL → open circuit; ≈0Ω → short circuit |

| PTC Thermistor (over-heat protection) | Positive temperature coefficient: Temp ↑ → Resistance ↑ sharply | Tens to hundreds of ohms | OL at room temp → open circuit; No resistance rise when heated → failure |

| Thermocouple (K/J type) | Generates mV signal; no fixed resistance | Loop resistance < 10Ω | No mV output → open circuit; mV deviation >50% → damage or wrong extension wire |

Quick Identification Tips:

NTC/PTC have a fixed resistance at room temperature.

Thermocouples do not—they show continuity but no stable resistance value.

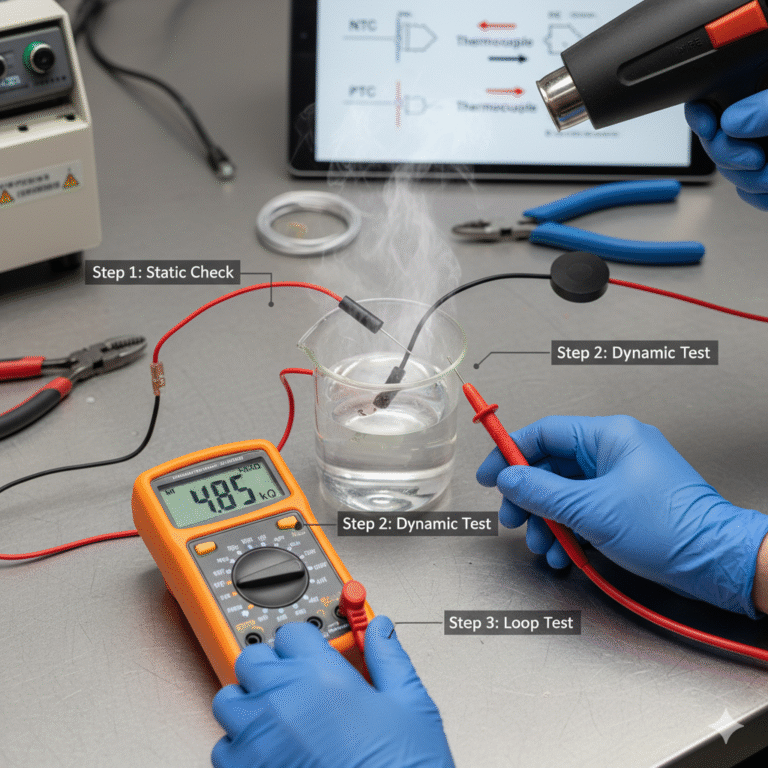

2. Three-Step Rapid Diagnosis Method

Step 1 — Static Room-Temperature Measurement (Identify drift/ open/ short quickly)

Power off and cool down the device to ensure the sensor returns to ~25°C.

Disconnect one lead of the sensor from the circuit to avoid interference.

Measure resistance using the correct multimeter range.

Interpretation:

Within ±10% of rated value → Sensor mostly OK; check wiring or controller.

Drift > ±30% (e.g., 10kΩ NTC showing 15kΩ or 5kΩ) → Sensor aging or drift.

OL / Infinity → Open circuit, broken wire.

Near 0Ω → Short circuit (NTC/PTC only).

Example:

A refrigerator NTC “103” reads 18kΩ at room temperature → drift → temperature reading too low → compressor may run continuously.

Step 2 — Dynamic Heating / Cooling Test (Check responsiveness)

Used when static resistance is “normal” but the device still behaves abnormally.

Heating methods:

Hold the sensor between fingers (≈35–40°C)

Low-temperature heat gun (≈50°C)

Warm water (for sealed sensors)

Cooling methods:

Electronic cooling spray

Ice pack (0–10°C)

Interpretation:

NTC Thermistor

Heat → Resistance must drop significantly (e.g., 10kΩ → 3–5kΩ)

Cool → Resistance should rise

No change = sensor failure

PTC Thermistor

When heated to 60–80°C, resistance should jump from tens of ohms to thousands

No sharp increase → faulty PTC

Thermocouple

Heat the hot junction → mV output must rise

K-type approx. 1.6 mV at 40°C

No mV change → open circuit or polarity reversed

Quick field trick:

Squeeze an NTC for 3 seconds:

Resistance ↓ by ≥50% = normal

No obvious change = faulty

Step 3 — Loop Continuity & Voltage Test (Identify wiring or controller issues)

If the sensor itself is normal, the fault is usually in:

1. Wiring / harness

Test continuity between sensor leads and controller terminals

Loop resistance should be < 1Ω

OL → broken wire or oxidized connector

2. Controller-side voltage

Many NTC sensors form a voltage divider. Measure sensor terminal voltage under power.

Interpretation:

Always 0V or full supply voltage → divider resistor open / short

Voltage fluctuates irregularly → controller input failure

Example:

An automotive coolant NTC (5kΩ) always reads full 12V → divider resistor on ECU is open → sensor is actually fine.

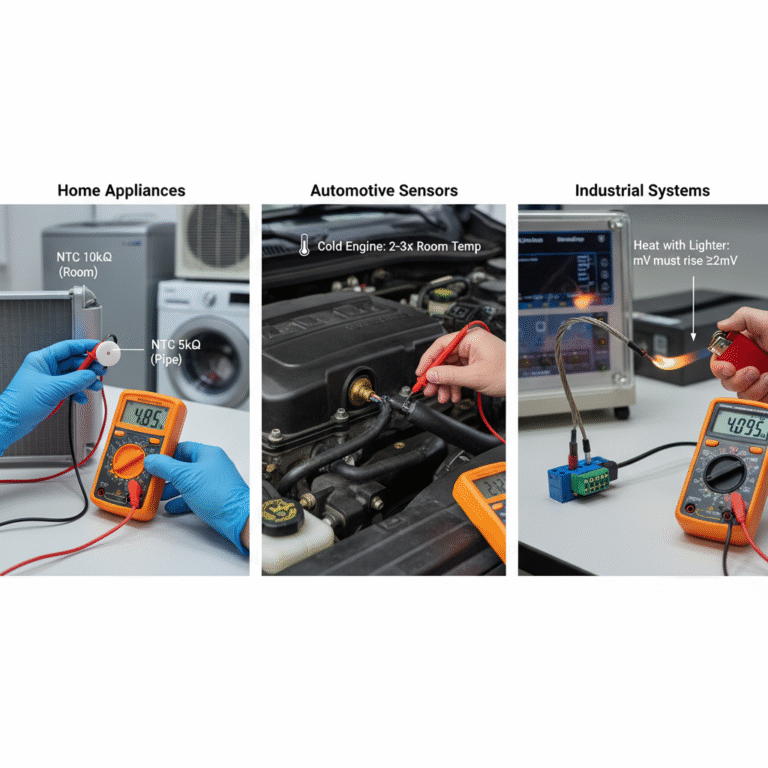

3. Application-Specific Diagnosis Tips

Home Appliances (AC, refrigerator, water heater)

Room sensor: NTC 10kΩ

Pipe sensor: NTC 5kΩ

±20% deviation → replace

Heating the sensor triggers compressor start/stop → sensor drift issue

Automotive Sensors (coolant, intake air)

Cold engine (0°C): Resistance should be 2–3× room-temp value

Hot engine (80°C): ≈1kΩ

No change → failed sensor

Wiring resistance >5Ω → connector corrosion

Industrial Systems (thermocouples)

Loop resistance <10Ω

K-type: 100°C ≈ 4.095 mV

Heat with lighter → mV rises by ≥2 mV

No rise → open circuit or wrong extension wire (very common)

4. Five Key Points to Avoid Misjudgment

Always measure resistance with power off.

Prefer measuring directly at sensor pins.

Understand NTC marking: “103” = 10 × 10³ = 10kΩ.

Meter ranges:

NTC: 20k / 200k range

PTC / wiring: 200Ω

Thermocouple: mV range

Diagnosis focuses on trend, not precise temperature (e.g., NTC must decrease when heated—if not, it’s faulty).