In industrial measurement and control, pressure transmitters are everywhere. But in vacuum systems, environmental monitoring, and high-precision applications, you may notice that engineers prefer absolute pressure transmitters instead of the more common gauge pressure transmitters.

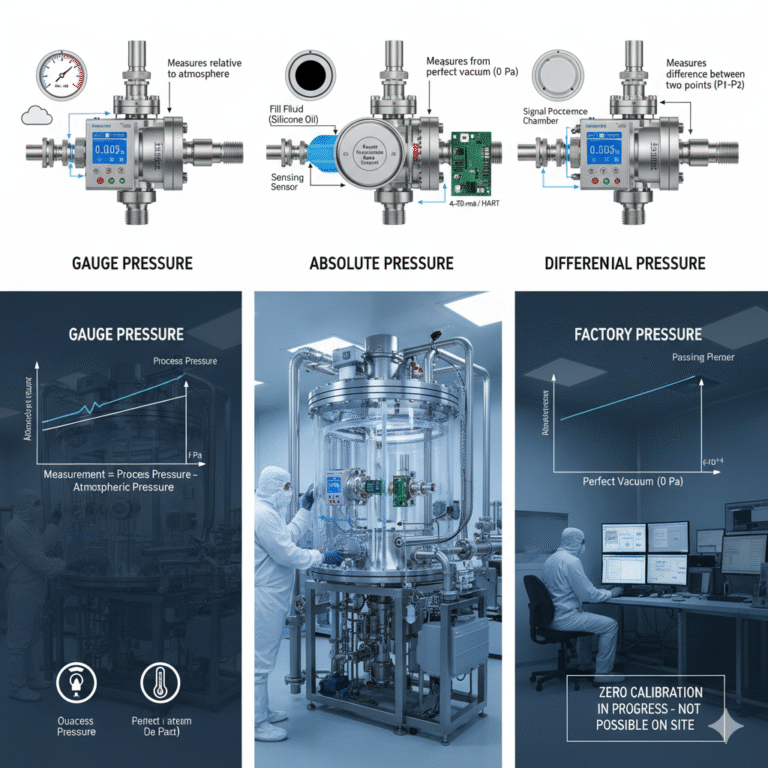

At first glance, they look similar, but the reference point and measurement logic behind them are fundamentally different:

Gauge pressure measures “How much higher than atmospheric pressure?”

Absolute pressure measures “How far away from a perfect vacuum?”

Understanding this difference is the key to selecting the right instrument and achieving reliable accuracy.

What Is an Absolute Pressure Transmitter?

An absolute pressure transmitter measures pressure relative to a perfect vacuum (0 Pa).

According to GB/T 17614.1-2015 Measurement Standard, absolute pressure takes complete vacuum as its reference point.

This means the transmitter’s internal reference chamber is permanently sealed and evacuated.

Unlike gauge pressure transmitters—which reference the atmosphere and therefore fluctuate with weather or altitude—an absolute pressure transmitter provides a true, stable reading independent of environmental changes.

In simple terms:

Gauge Pressure (Pg): Pg = Process Pressure − Atmospheric Pressure

Absolute Pressure (Pa): Pa = Process Pressure (since vacuum = 0)

Gauge pressure measures a difference, while absolute pressure measures the actual value.

Structure and Working Principle

An absolute pressure transmitter typically consists of these components:

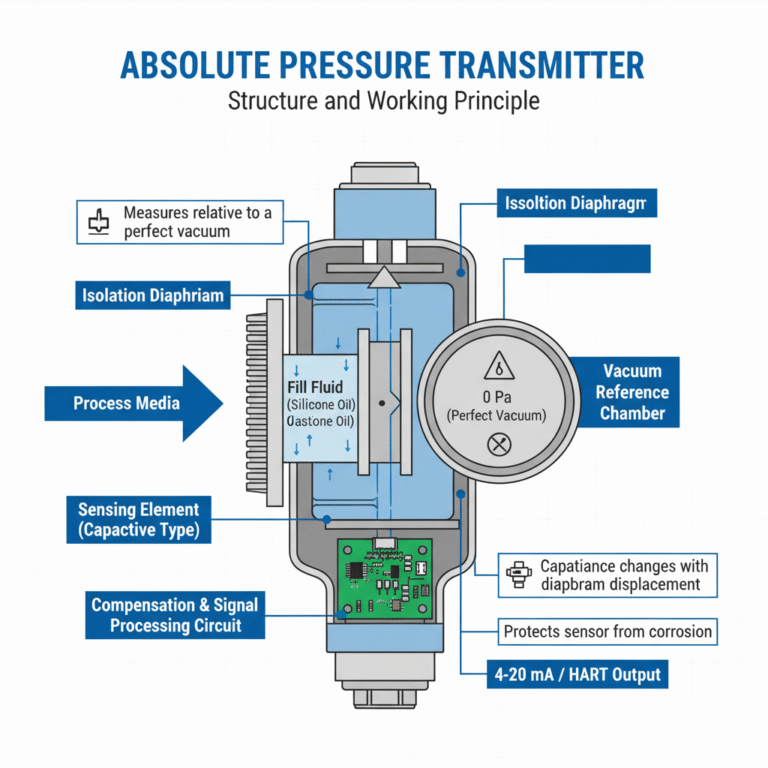

1. Isolation Diaphragm and Fill Fluid

The process media applies force to the isolation diaphragm. This force is transmitted through fill fluid (such as silicone oil) to the sensing element.

This protects the sensor from corrosion or contamination.

2. Vacuum Reference Chamber

One side of the sensing element is sealed in a permanent high-vacuum environment (typically <10⁻⁴ Pa).

This chamber provides the absolute “zero point”.

3. Sensing Element (Capacitive or Piezoresistive)

Capacitive sensors: Measure diaphragm displacement by detecting changes in capacitance.

Piezoresistive sensors: Detect strain on a silicon chip via changes in resistance.

4. Compensation and Signal Processing

The analog signal goes through temperature and linearity compensation before being output as:

4–20 mA

1–5 V

HART / Modbus digital communication

High-quality absolute transmitters can reach ±0.04% FS accuracy and long-term stability better than 0.1% FS per year.

Zero Calibration — Why It Cannot Be Done On Site

Unlike gauge pressure transmitters, where zero equals atmospheric pressure, the zero point of an absolute pressure transmitter is a perfect vacuum.

Key calibration facts:

Factory calibration: Must be performed under controlled vacuum using a high-vacuum chamber.

Field calibration: You cannot simulate a vacuum at the job site; only minor trimming is possible.

Do not attempt full re-zeroing in the field—it will compromise accuracy.

Engineering tip:

If your accuracy requirement is better than ±0.05% FS, always rely on the factory’s vacuum-based zero calibration.

Typical Applications of Absolute Pressure Transmitters

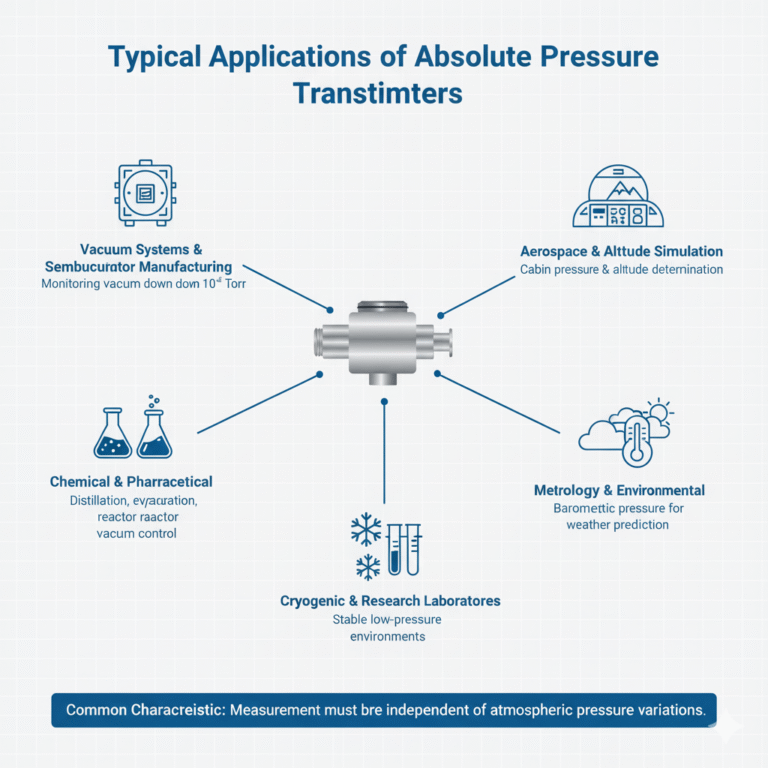

Absolute pressure transmitters are used where atmospheric fluctuations would cause unacceptable measurement errors.

Typical industries include:

Vacuum systems and semiconductor manufacturing

Monitoring vacuum chambers down to 10⁻³–10⁻⁶ Torr.Aerospace and altitude simulation

Cabin pressure monitoring and altitude determination.Chemical and pharmaceutical processes

Controlling distillation, evaporation, and reactor vacuum levels.Meteorology and environmental monitoring

Measuring barometric pressure for weather prediction or altitude compensation.Cryogenic and research laboratories

Ensuring stable low-pressure environments.

Common characteristic:

Measurement must be independent of atmospheric pressure variations.

Absolute vs Gauge vs Differential Pressure — How to Choose

| Application Scenario | Recommended Type | Typical Range | Calibration Basis |

|---|---|---|---|

| Steam pipelines, tanks | Gauge pressure | 0–2 MPa | Atmospheric zero |

| Vacuum drying oven | Absolute pressure | 0–100 kPa abs | Vacuum zero |

| Semiconductor chamber | Absolute pressure | Ultra-low pressure | High-vacuum reference |

| Filter clogging or flow | Differential pressure | ±50 kPa | Dual-side calibration |

Selection principles:

Want to know pressure relative to environment? → Gauge type

Need the true physical pressure value? → Absolute type

Need pressure difference between two points? → Differential type

Common Misunderstandings and Correct Interpretations

Misconception 1: Absolute pressure transmitters can be zeroed on site

❌ Not true — zero = perfect vacuum, which cannot be generated in normal field conditions.

Misconception 2: Absolute types are “more advanced”

❌ They are not more advanced—they simply use a different reference point.

Accuracy depends on model, not the measurement type.

Misconception 3: Gauge and absolute transmitters can be interchanged

❌ They cannot.

An absolute transmitter reads about 101.3 kPa higher than a gauge transmitter under atmospheric conditions.

Engineering Insights and Practical Takeaways

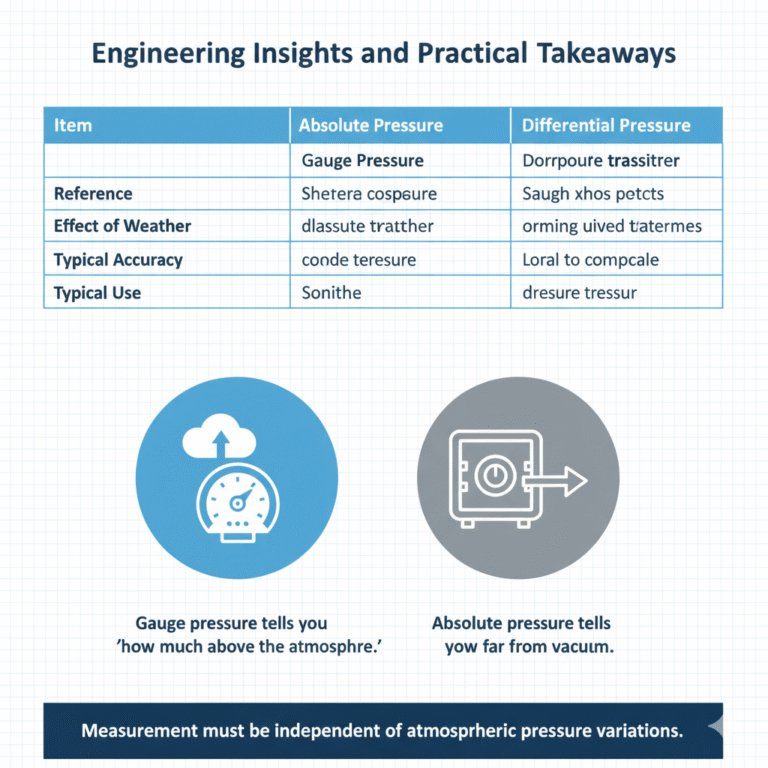

| Item | Gauge Pressure | Absolute Pressure | Differential Pressure |

|---|---|---|---|

| Reference | Atmosphere | Vacuum | Two process points |

| Effect of Weather | Yes | Minimal | Depends on system |

| Typical Accuracy | Medium | High | High |

| Typical Use | Process lines, liquid level | Vacuum, barometric, aerospace | Flow, filter monitoring |

In essence:

Gauge pressure tells you “how much above the atmosphere.”

Absolute pressure tells you “how far from vacuum.”

Conclusion

Absolute pressure transmitters are not simply “more advanced versions” of gauge transmitters.

They serve a different purpose and provide a measurement that remains stable even when atmospheric pressure changes.

Whether you are working with vacuum processes, semiconductor equipment, aerospace systems, or precision research instruments, understanding absolute pressure is essential for achieving accurate, reliable, and traceable measurement results.