Cable manufacturing is a highly integrated process involving raw material preparation, conductor processing, insulation and sheathing extrusion, quality testing, and final packaging. To maintain stable product quality and support long-term customer reliability, manufacturers must optimize across the entire production chain.

This article summarizes eight key dimensions of optimization that significantly enhance product quality, reduce defects, improve efficiency, and ensure compliance with international standards.

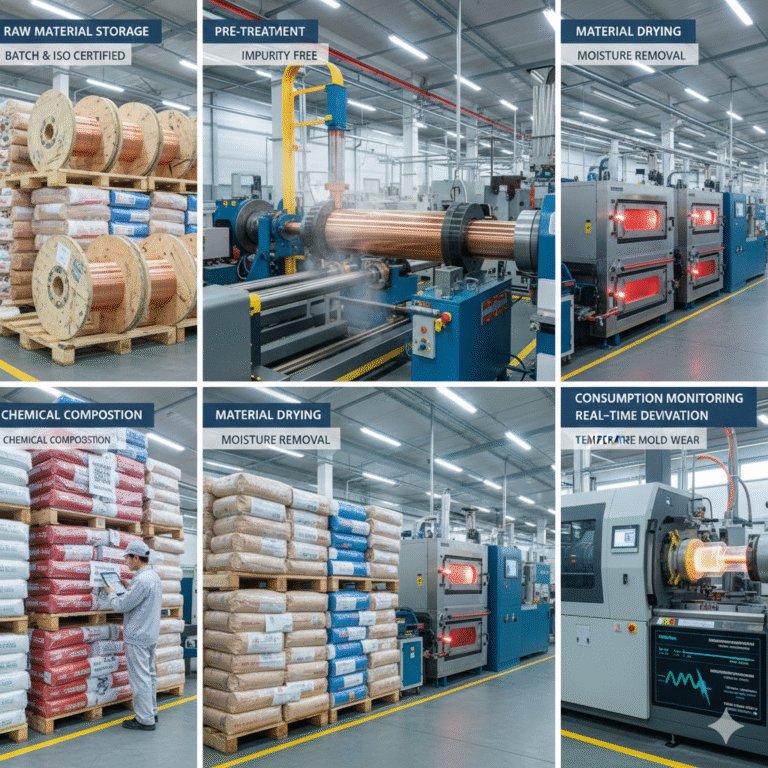

1. Raw Material Control: Ensuring Quality from the Source

Raw materials directly determine the electrical, mechanical, and environmental performance of cables. Effective material control greatly reduces defect rates.

Supplier Management

Establish an A/B/C supplier rating system, prioritizing ISO-certified manufacturers.

Require each batch to include chemical composition, mechanical properties, and weather/temperature resistance reports.

Use dual sourcing for critical materials such as copper conductors and XLPE compounds to avoid supply interruptions.

Material Pre-Treatment

Copper/Aluminum Rods:

Inspect diameter tolerance and oxidation levels.

Clean with hot air and ethanol to avoid impurities entering the conductor.

Insulation & Sheathing Compounds:

Pre-dry materials to remove moisture and prevent bubbles or pinholes during extrusion.

Store by batch and material grade to prevent mix-ups.

Consumption Control

Set standard consumption values for each cable type. Monitor deviations in real time and trace causes such as temperature fluctuation or mold wear.

2. Core Process Optimization: Improving Manufacturing Consistency

2.1 Conductor Stranding

Control stranding pitch to ensure proper flexibility and prevent resistance deviation.

Use tension-synchronized devices to prevent loose stranding or broken wires.

Apply online polishing and dust removal to eliminate metal burrs that may damage insulation.

2.2 Insulation and Sheath Extrusion

Create customized temperature profiles for materials such as XLPE, PVC, and HDPE.

Maintain stable extrusion pressure and line speed to ensure uniform insulation thickness.

Use high-precision molds to improve concentricity and reduce insulation eccentricity.

2.3 Crosslinking (for XLPE Cables)

Control temperature, pressure, and crosslinking time according to insulation thickness.

Implement controlled cooling to prevent internal stress or cracks after crosslinking.

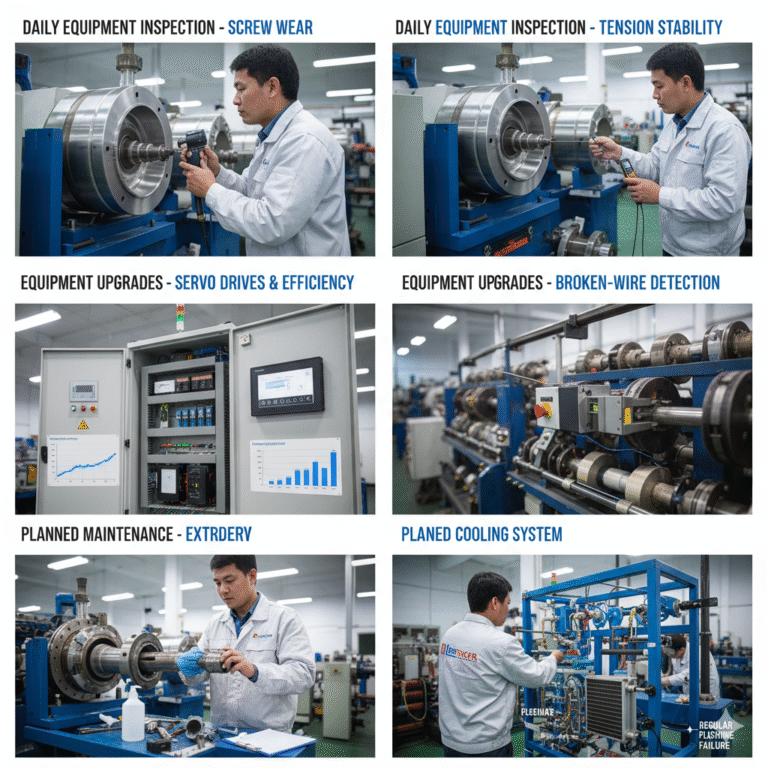

3. Equipment Management: Reducing Downtime and Ensuring Stability

Daily Equipment Inspection

Key checkpoints include:

Screw wear on extruders

Temperature controller accuracy

Stranding machine tension stability

Calibration of spark testers and diameter gauges

Equipment Upgrades

Replace outdated control systems with servo and variable-frequency drives to reduce energy consumption and speed fluctuations.

Add broken-wire detection to stranding machines.

Upgrade crosslinking lines with automatic temperature/pressure control systems.

Planned Maintenance

Perform regular maintenance on extruder screws, bearings, and cooling systems to prevent unexpected failures.

4. Quality Assurance: Detecting Defects Early

A robust QA system allows manufacturers to identify defects at the earliest stage.

FQC – First Article Inspection

Before mass production, test:

Conductor resistance and surface quality

Insulation thickness and concentricity

Spark test performance

IPQC – In-Process Inspection

Conduct inspections after key processes such as stranding, extrusion, crosslinking, and sheathing.

OQC – Final Inspection

Tests include:

Insulation resistance

Withstand voltage

Mechanical bending and tensile strength

Weathering and oil resistance

Defect Traceability

Use 5-Why analysis to identify root causes and implement corrective actions.

5. Production Efficiency: Reducing Cycle Time

Lean Production Planning

Group orders by material and size to reduce mold-changing time.

Use daily production plans linked with QC checkpoints.

Solving Bottlenecks

Use dual crosslinking chambers for continuous operation.

Apply multi-head stranding for large conductors.

Introduce automatic take-up and wrapping machines to improve packaging efficiency.

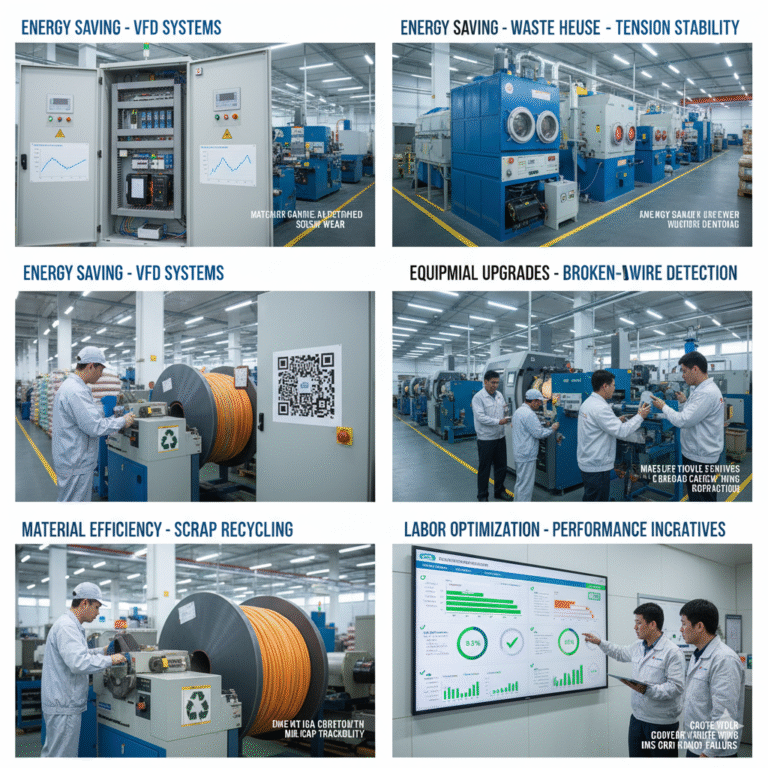

6. Cost Optimization: Reducing Waste Without Sacrificing Quality

Energy Saving

Install variable-frequency drivers on major equipment.

Reuse crosslinking waste heat for drying materials.

Apply LED lighting and automation in non-production zones.

Material Efficiency

Optimize extrusion parameters to minimize scrap.

Recycle non-critical scrap materials under controlled ratios.

Use QR-code labels to reduce paper waste and improve traceability.

Labor Optimization

Train multi-skill operators.

Combine related positions to reduce redundancy.

Implement performance-based incentives linked to yield, energy use, and material consumption.

7. Compliance & Environmental Protection: Meeting Industry Standards

Compliance

Follow GB/T, IEC, and relevant national standards for power and control cables.

Maintain certification such as CCC and production licenses.

Keep raw-material and QC documentation for a minimum of five years.

Environmental Management

Treat VOCs using activated-carbon and catalytic oxidation systems.

Recycle cooling water and maintain zero wastewater discharge.

Categorize and recycle metal and plastic waste according to environmental regulations.

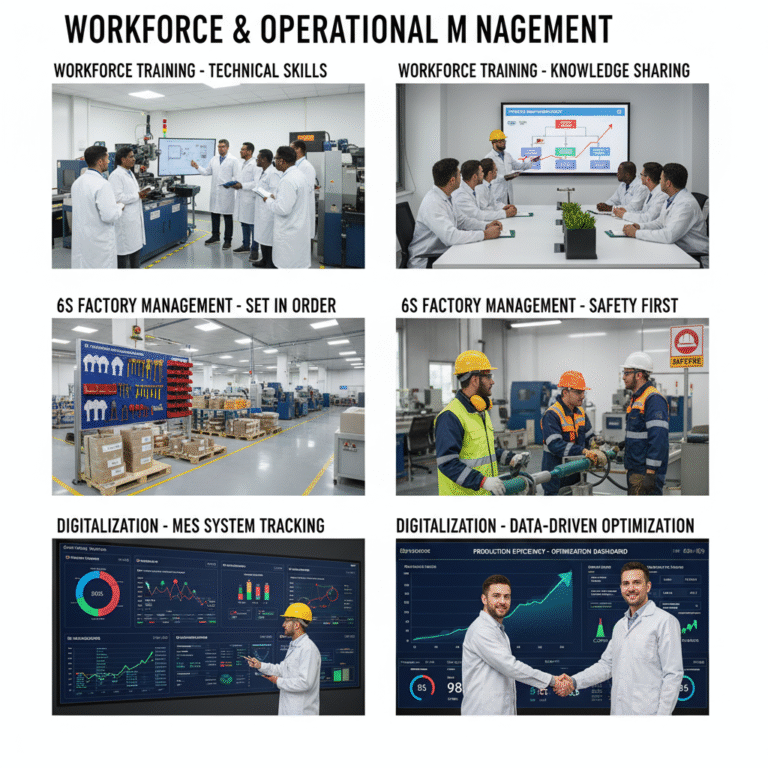

8. Workforce & Management: Building a Strong Operational Foundation

Training System

Provide structured onboarding, technical training, and periodic testing.

Share process-improvement case studies to strengthen team skills.

6S Factory Management

Implement Sorting, Set-in-Order, Shine, Standardize, Sustain, and Safety across all workshop areas.

Digitalization

Introduce MES systems to track:

Machine parameters

Material usage

QC results

Production efficiency

This enables data-driven optimization across the factory.

Conclusion

Optimizing cable manufacturing requires a comprehensive approach across raw materials, core processes, equipment, quality assurance, cost control, environmental compliance, and workforce development. By strengthening each link of the production chain, manufacturers can significantly improve product stability, reduce overall cost, and enhance competitiveness in global markets.